Green – Lean – Digital: The Factory of the Future

Green – Lean – Digital: The Factory of the Future

Listen to the blog here:

In the discrete manufacturing, plant engineering, food & beverage, and automotive sectors, applying lean principles and automation has been and will remain evergreen when striving for efficiency gains. The golden rule appears to be: the more efficient and flexible the manufacturing processes are, the more profitable and competitive a company will be. Holding true, keeping your processes as lean as possible will build the foundation for the factory of the future, but the best process is still the one that doesn’t exist. The next big milestone on the path towards efficiency and flexibility is digitalization. Production companies already started transitioning from analog to digital information as well as collecting and connecting data throughout the value chain. Through digitalization, production complexity becomes manageable, behavior of machines and assets predictable, disturbances in supply chains transparent, production systems quickly adaptable and as a result, productivity overall rises.

However, the growing importance of sustainability as well as decarbonization of supply chains and own operations is adding additional requirements and challenges for the digital transformation of factories. There is a new goal to reach now that making production sustainable is no longer an option – it’s a must. Once your factory is lean and digital, what does it take to make it green as well? What are the key components of the factory of the future?

Trends and challenges in industrial manufacturing and production

Digitalization and technology will heavily accelerate by 2030. However, according to the World Economic Forum (WEF), over 70% of the global production sector is still languishing in pilot phases for the Industrial Internet of Things (IIoT). As a consequence, only very few companies have effectively deployed advanced digital and sustainable production at scale.The potential to untap is still vast. Simultaneously, we see digital solutions and services becoming increasingly ready-to-scale, unleashing tangible benefits of digitalization for shopfloors and manufacturing environments in all industries.

In fact, establishing a factory that is at the same time green, lean, and digital will enable companies to outperform competition in both profitability and sustainability. On the other hand, there are several key challenges to address when kick starting your factory digitalization journey.

In manufacturing, as in any other business, potential transformations will continue to take place in a VUCA (volatility, uncertainty, complexity, ambiguity) environment, which becomes even more visible in today’s turbulent times. Manufacturers will need to operate in a world that is rapidly changing. Events will become less predictable and therefore less reliable for planning. The world’s complexity and ambiguity mean risking poor decision making based on ambiguous information, especially when failing to look beyond the horizon of one’s own operations and integrating the entire ecosystem in decision making. Despite this, if one thing is certain, it's uncertainty, and it is here to stay. We just have to find a way to cope with it.

There is also a certain probability of getting lost in digitalization – a commonly observed pitfall. Companies tend to rush into the idea of implementing IIoT solutions at high speed. However, in most sectors, executives often lack the knowledge to select, adopt and scale the right technologies that could be most beneficial for the company. They tend to become infatuated with a technology without considering the impact and benefit for their business. Worst case scenario, this technology doesn’t fulfill its purpose. Furthermore, most plans and roadmaps lack prioritization, also resulting from a lack of knowledge in digitalization and automation. In short, we see plenty of organizations missing consistent knowledge to elaborate, prioritize and evaluate the benefits of factory digitalization. These organizations will always under- or overestimate the potential impact of these solutions when scaling-up. Without understanding the business value, companies might become entangled in proof of concepts and pilot phases that will never scale sufficiently. The more complex the digital environment gets, the more crucial it becomes to keep a compass with clear direction to avoid getting lost in the digitalization jungle.

In addition, there is another major challenge that shares the spotlight. An ageing population and society means that the labor market will dwindle mid-and-long-term, especially in Europe and the Americas, but also already in some Asian countries. This demographic shift will decrease the available workforces significantly. Therefore, existing staff members must be encouraged and supported by automation and digitalization to facilitate their operations and productivity for a longer period. There is also a need to relieve the shopfloor operator from physical exertion e.g., by handling robotics and automation in conveyor technology, while nourishing their intelligence and creativity supported by digital solutions e.g., through worker guidance or quality assurance. Digital transformation will not work without the right people, so keeping and training them is of highest priority.

Fourth and finally, executives must determine how to implement stricter emissions regulations to achieve sustainability targets for their supply chain and manufacturing processes. ‘Carbon neutral’ is mostly, while still perplexing, measured and realized for the process. In Europe, manufacturers are beginning to tinker with the concept of BAT (best available techniques) to limit emissions from manufacturing. As defined by the OECD; “[…] ‘best available techniques’ means the most effective and advanced stage in the development of activities […] to reduce emissions and the impact on the environment.” However, utilizing data to accurately determine the carbon footprint is highly challenging, especially as supply chains become increasingly complex.

Nevertheless, vertically and horizontally increasing connectivity within entire supply chains allows, based on common digital solutions and platforms, to create this transparency to identify the levers needed to continuously monitor, balance and reduce the carbon footprint.

North stars for the factory of the future

Addressing those challenges takes more than just a plug-and-play solution or deploying applications from an App Store in the systems and assets. The digital transformation in factories comes with a package of unique requirements and ongoing disruptions, which must be opened and addressed to reach the Factory of the Future vision. We need to realize that transformation applies to more than just the factory line or floor. Digital transformation encompasses the whole of your organization, comprising your processes and technology, with people being the stars of the show.

Before transforming your company, you need to identify your north stars. In manufacturing, there are three specific goals to shoot for to create the Factory of the Future.

Productivity is the most obvious one, and it has been there from the start. Even without digitally transforming the factory, a yearly increase of 10 percent is optimistic for many manufacturers. Without a doubt, this increase in productivity is the bottom line to creating lasting commercial success and ensuring competitiveness. These productivity boosts can already be achieved by applying classical lean processes and administration as well as connectivity and automation.

Achieving flexibility is another important destination for digital transformations. The factory of the future will need to meet market uncertainties head-on. Variations in demand, smaller lot sizes and increased uncertainty in complex supply chains will have to be tackled while avoiding, or even better, cutting waste in factory processes. Automation and cutting-edge technologies like IoT and AI, as well as the transparency achieved through their implementation, can help executives reach that flexibility destination.

Sustainability is not only critical for meeting BAT-compliant production models, but methods in manufacturing that support sustainability goals, achieved with digital transformations, are crucial for combatting climate change. Additionally, public opinion on climate change is shifting towards a demand for more sustainability. As a result, signaling the achievement of your sustainability and decarbonization goals, through digital transformation and energy efficiency, will also improve your corporate image.

Before transforming your company, you need to identify your north stars. In manufacturing, there are three specific goals to shoot for to create the Factory of the Future: productivity, flexibility and sustainability.

How to strive towards the factory of the future?

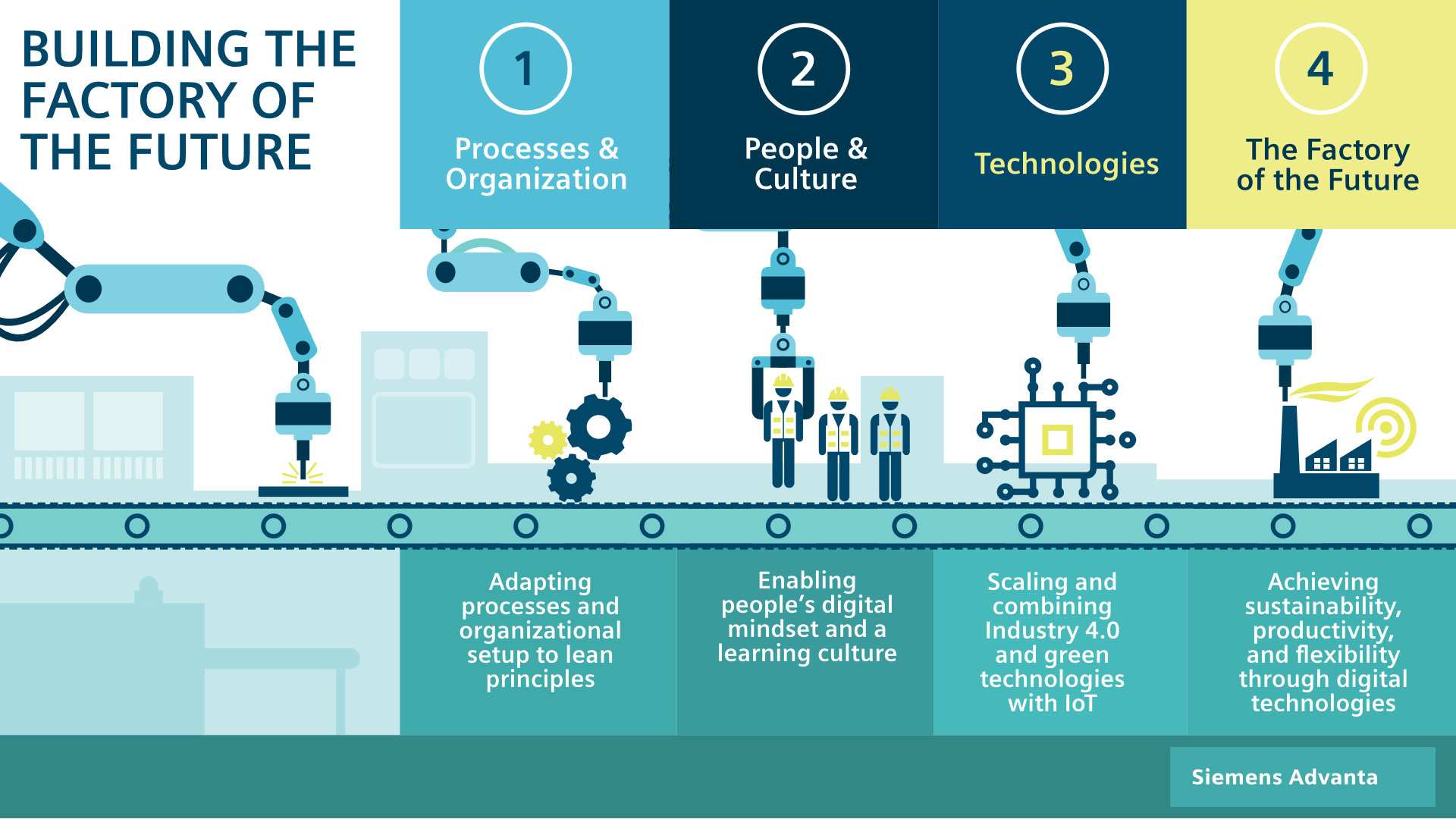

To create a sufficient backbone for the digital factory of the future, you need to foster changes in the areas of processes and organization, people and culture as well as scaling technologies. It is crucial to understand that digital transformation affects every aspect of an organization.

Adapting processes and organizational setup to lean principles

Peeking into one our client’s sites, cost pressures demand that companies streamline operations and add more digitalization to achieve higher efficiency in manufacturing processes. Siemens’ Lean Digital Factory approach offered the necessary transparency to demonstrate to our client how to successfully use digitalization in a discrete industrial manufacturing environment. What we often still see are missing interfaces for horizontal and vertical integration, overcomplex processes and systems, and many uncoordinated or even competing initiatives that over work the staff, resulting in a chaotic working atmosphere.

Companies have always been aiming for process improvements that lower costs and time-to-market. By doing so, efficient, waste-free processes are (still) the way to go to maximize the value that modern technology offers. Digital technology can be applied to all processes in production, logistic, administrative processes, and even the organizational structure. The organizational structure itself helps to efficiently organize people’s responsibilities and communication channels throughout the process.

In the factory of the future, processes are designed to be simple, built on direct communication and fewer interfaces. Building and adapting processes with a lean and digital mindset means avoiding uncertainty and unclear responsibilities. Processes and organization need to be programmed to consider the opportunities and limits of digitalization, e.g., for communication and general information flow. As a result, you can develop touchless processes that are built on data-driven decisions.

In the end, digitalization will enable progress, and it will foster innovation by giving transparency on current processes and scenarios and making data-driven decisions based on these insights. This approach will boost your productivity to new dimensions to reach your sustainability and flexibility goals.

Enabling people’s digital mindset and a learning culture

The pursuit of technological progress, efficiency and sustainability can foster a culture of continuous development, but siloed knowledge, that has traditionally rested with experienced and qualified individuals, will need to be extracted and shared company-wide. It needs to become institutional knowledge.

Broadly speaking, what needs to be fostered is an environment in which employees appreciate your company’s vision and translate it into action. There needs to be a shared vision in place to achieve the common goals across your enterprise. As a result, your digital factory can be a place where employees see a particular problem as an opportunity to improve the entire enterprise. You need to make your people part of the digital solution from the get go.

To successfully progress in digitalization, your organization needs to motivate and engage employees to build a culture with digital elements. Initiating the change to an employee digital mindset will coincide with raising curiosity of the new digital work environment. This can range from building expert communities, that work together across organizations and hierarchies, to re-thinking your collaboration in interactive online events and workplace planning.

This change requires constant training and aiming towards attaining and building the right mix of competences. In order to do this, you need to identify your individual skills gap and areas for improvement. In many cases, this means re-thinking job profiles and offering individual learning opportunities. You must also make sure to foster digital learning and give employees the stage to share their knowledge. Mentoring and coaching can be a great addition to the set methods of learning from within and from outside your organization. Remember, people make digital transformations happen while technologies are only the tools needed to get there.

Scaling and combining Industry 4.0 and green technologies with IoT

Technological advancements have been the main driver of past industrial revolutions and are still essential for industry 4.0 development. Modern technologies such as cloud computing, machine learning and the industrial internet of things (IIOT) create a connected organizational environment that allows constant exchange and analysis of data between systems and physical assets.

To ensure a consistency of successful implementation, project companies require scalable and proven solutions that build on interfaces and scalable design. This is facilitated by using reference architectures and choosing from existing best practice solutions from an established solution library. To achieve net zero, this library should also include solutions that serve the main purpose of neutralizing the carbon footprint.

The crux lies in the successful implementation of these digital solutions. You need to make sure your strategy allows you to collect accurate and continuous data, and this is only realistic when building on blueprints and design principles for infrastructure and leveraging scalable solutions.

Connecting the worlds of information technology (IT) and operations technology (OT) will do the trick to build the factory of the future. While these areas did not particularly overlap in the past, the full integration of IT and OT will create unique insights generated from plant and operations data. With data-enabled technology platforms, the organization can gain transparency and smooth access to existing and planned digital solutions. In the end, choosing the right green and digital solutions, connecting them based on existing blueprints, and making them scalable will be the success factors for your factory of the future. The technology to tackle the climate crisis is here – we just need to leverage it correctly.

By doing so, cloud-based networks, AI, and automation will cause more disruption in the next five years than anything we’ve seen before, like in the Automotive sector.

Conclusion

The factory of the future will realize its full potential for sustainability, productivity, and flexibility by transforming not only processes but people, organization and technologies. Scalable digital solutions will play a key role in this transformation. Only with a holistic factory digitalization approach in the palm of your hands will your factories be able to address the challenges of tomorrow.

Digital solutions will also be our only hope when trying to tackle the climate crisis. Producing goods in the most resource efficient and sustainable way will only be possible if you have the data prepared and analyzed to make the right decisions. Remember, there is no sustainable transformation without a digital one.

Siemens Digital Industries has launched an ongoing program that has been in place for four years. Involving over 30 plants, Siemens has taken more than 800 measures in five key areas resulting in an 8% increase in productivity. The program is currently scaled up to incorporate more factories, regions, and businesses. This way, Siemens will reach its ambitious goal of staying competitive in the market and paving the way for its sustainable and carbon neutral future: Green, Lean and Digital – the Factory of the Future!

Free whitepaper

Based on our unique experience in digital factory environments, we identified several company as well as use case specific factors to make the groundbreaking decision between edge and cloud. Download our whitepaper and learn which factors to consider when unlocking the full potential of your IIoT journey!

Our expert

Author

Digitalization with Purpose

Digitalization with Purpose – Uncovering Data to Create Utility Stakeholder Value

All data is not equal and data access alone will not deliver value to your enterprise.

For a simple statement, it is one that carries significant consequences. For every bit and byte of data exchanged from central, enterprise platforms to edge and connected devices or assets, there is a specific cost and value to the business and its stakeholders.

At a unit level the TOTEX (total expenditure, including upfront capital outlay and ongoing operational costs) associated with each byte of data may be small; however, with the exponential growth of data, related costs will continue to rise.

While that rise may not be as steep as the growth in data volume overall, the continuing fall in the cost of data storage is flattening out, meaning businesses need to look more closely at how they manage their data to keep costs under control.

The accumulation of data in isolation does not yield outcomes or deliver business returns. Data must be consolidated and consumed to turn it into value.

Data offers new opportunity

So how should data be viewed strategically, if not as a direct source of value but one with an inherent cost? Ultimately, data is an enabler – it enables use cases and applications, which solve the business challenges of today and support the ongoing advancement of an organisation for its stakeholders.

The potential value of data is equally reflected within the art of the possible – the emerging topics and innovative ideas that are yet to be conceptualised by the best and brightest of our global society yet to be brought to market which will increasingly rely on data to disrupt and progress.

Clearly data and information provide a basis to construct value and insight, which would be inaccessible without it. The emerging data-driven solutions of today and tomorrow will be a key facet within the necessary evolution and transformation of our utilities, cities and societies, as part of a net carbon zero future.

However, Rome was not built in a day and digitalisation represents more of a journey than a destination. It is vital, therefore, that we acknowledge that there is no silver bullet when it comes to digital and data enablement.

Challenges will be witnessed throughout the journey of individual organisations, evolving based on the maturity and capability of the existing systems, strategy and personnel at their disposal.

Understanding digitalisation challenges for utilities

As we uncovered during my last blog, global spend within the Industrial Internet of Things (IIOT) is rising. In 2020 it was valued at USD 216.13bn, 20% of which is directly attributable to the energy sector. Investment at this scale will create transitional risks for utilities, but these can be mitigated with a prudent approach to business digitalisation strategy, planning, implementation and management.

As data volumes grow throughout the energy sector, there will be an unequivocal need to provide robust cyber security, auditability, standards adherence etc, and to control processes for stakeholder access to data. With individual platforms and systems, this can be challenging enough; when considering the wider direction of enterprise IT/OT integration, these headaches will be compounded.

A greater focus upon platform and system integration will increase the pressures on legacy systems to scale and meaningfully participate within an increasingly open digital environment. It is not too far-fetched, therefore, to suggest that there will be a push from both internal stakeholders and external suppliers to procure new, digitally native, application rich products and systems which can critically scale.

This increases the risk of stranded assets throughout the enterprise estate, both today and tomorrow. For example, how confident are businesses that software and products procured today will scale and grow with your organisation, aligned to your respective digitalisation strategy, throughout the mid-to-long term?

The sunk cost of data

Stepping away from technology, challenges also emerge when considering the sunk cost of data and its management, not just in storage and communications, as noted previously, but also in terms of the digital fluency of a workforce.

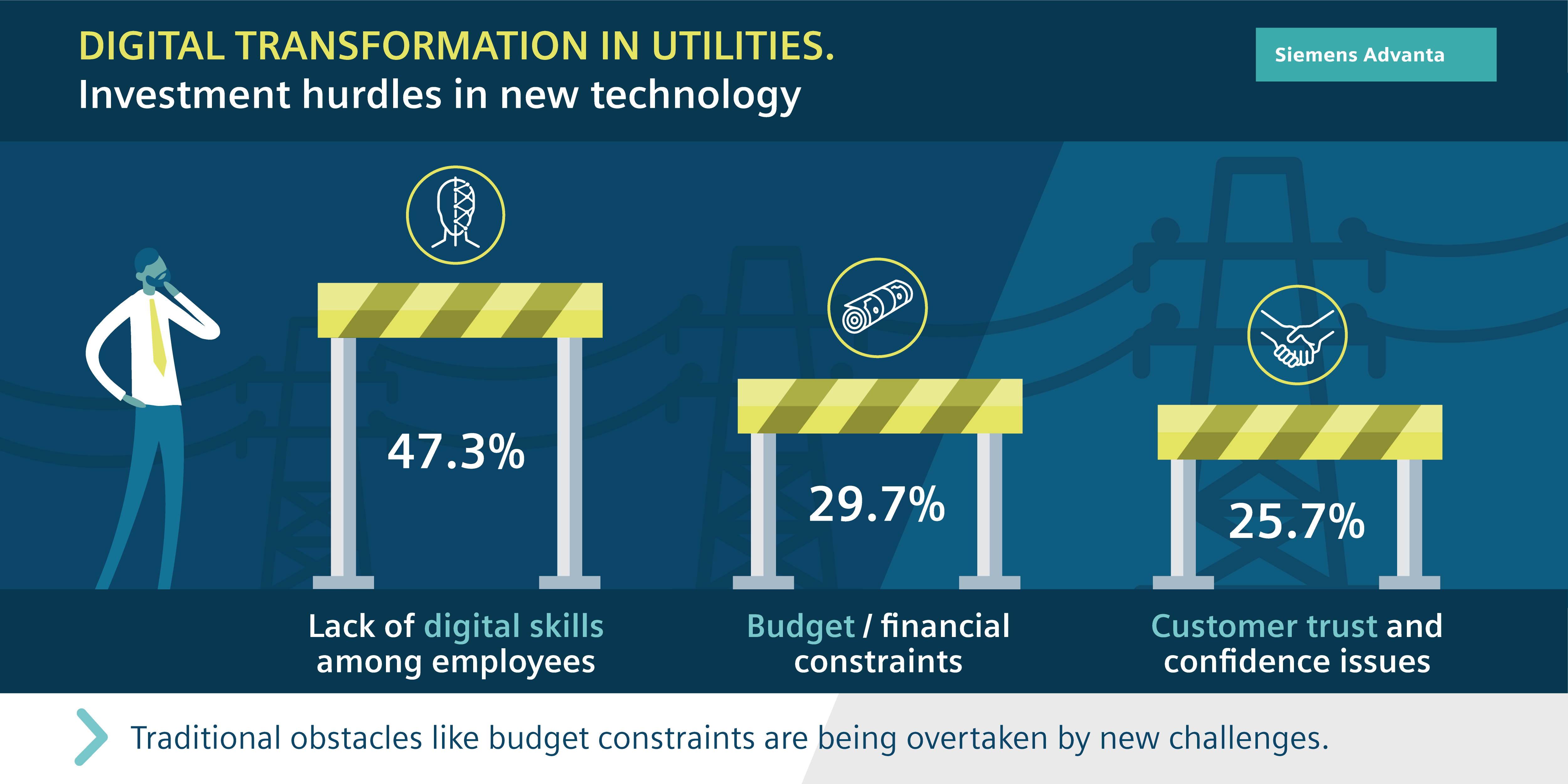

Tellingly, 47.3% of European transmission and distribution operators questioned in IDC's 'Utilities Core Business Transformation Survey 2021' confirmed that a lack of digital skills amongst employees was the largest internal challenge when investing in new technology. In comparison, the second highest challenge was budget and financial constraints, capturing 29.7% of the respondents’ concerns.

Then consider the challenge associated with determining the business impact of these investments. How frequently is Return on Investment (ROI) calculated and evaluated within digital procurement? How is this tracked throughout the operational lifecycle of the system?

Furthermore, how are the associated Environmental, Social and Governance (ESG) benefits monitored? These are aspects that are becoming increasingly important within the push for meaningful change in terms of reduced in carbon consumption over the coming decade. If businesses are unable to accurately document determine these required outcomes and benefits ahead of procurement up front, it is highly likely such KPIs will not be monitored nor realised during the lifecycle of the solution.

These points contextualise some of the typical challenges faced by utilities as part of digital transformation programmes. It is increasingly clear that the success of digitalisation initiatives depends on the provision of a client-orientated solution and outcomes, rather than potentially siloed digital products and offerings.

Avoiding pitfalls – how can digitalisation be de-risked?

Regardless of macro similarities, no two utilities are the same. Each business requires results consistent with its strategic direction, encompassing the underlying enterprise estate.

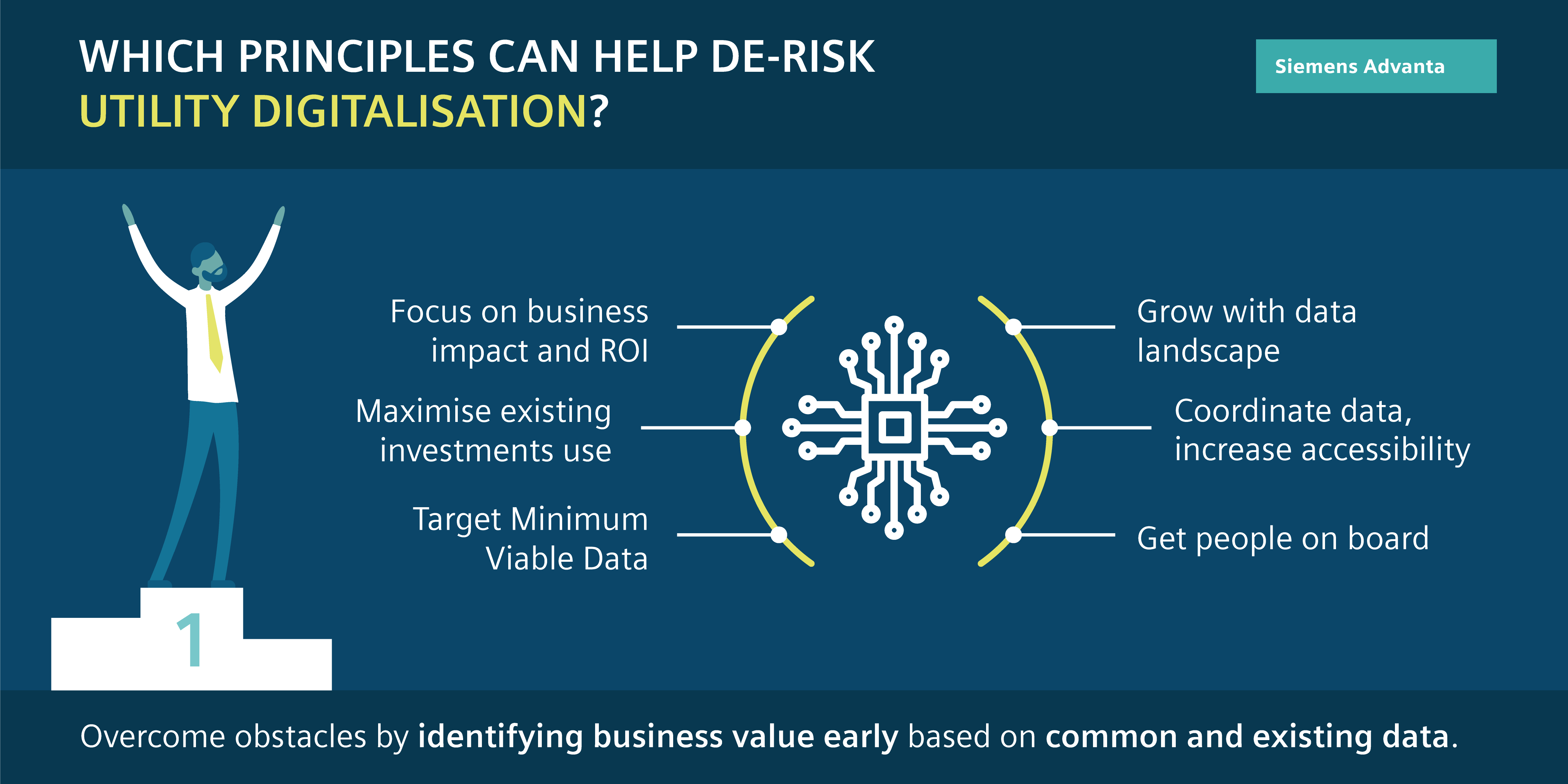

A client-driven solution goes some way to addressing nascent risk, though equally important is that solutions are underpinned with best-in-class common values – an effective set of guiding principles. Guiding principles offer consistency in approach, incorporating decades of best practice to minimise inherent risk within complex delivery.

Focus on business impact and ROI – All things data and digitalisation have inherent cost but this need not be a barrier to progression. The supporting business case for each investment should demonstrate where and how value can be created throughout the organisation.

Transparency in terms of target ROI and ESG benefits is critical because these elements provide justification as part of a robust business and investment case. Documenting how a utility company will benefit against its individual operational and strategic KPIs is a must.

Maximising the use of existing client investments – Throughout the operational lifecycle of any system there will be the need to maintain and even extend or enhance – activities which bear consequential cost. Driven by client need, building around and upon existing core systems to focus efforts within the enterprise IT estate can maximise existing capabilities and skills throughout the business, whilst limiting investment in new technologies.

If, for example, core systems can be enhanced to sanitise valuable data for wider use, this is likely to reduce investment cost in the enabling efforts and associated spend, thus improving ROI when creating new data-driven value.

Target Minimum Viable Data (MVD) – If not all data is equal, the task of prioritising which data offers most utilisation potential and consistency to support impactful use cases and applications is a vital activity. Determining what data exists, and what is accessible, creates a bespoke data landscape for your business – the MVD baseline.

Grow with your data landscape – As digitalisation is a journey rather than a destination, generating the MVD baseline to rapidly enable value with accessible data is critical. As your business and its ecosystem of increasingly connected technologies and digital personnel develop, so can the MVD baseline itself.

Therefore, providing a mechanism through open and scalable APIs for example, to integrate additional data from existing or emerging sources is essential to enrich and unlock additional digital value.

Coordinate data and increase accessibility – In collating a reusable MVD baseline, the opportunities to increase transparency and structurally open access to internal business stakeholders (subject to relevant access and governance requirements) becomes increasingly compelling.

How could the business benefit with an increasingly transparent approach to inter-departmental data access? What business challenges could be solved in new and innovative ways? In post-COVID operations, could data access and transparency support social cohesion for remote staff and increase digital fluency of the workforce?

The recent Gartner CDO Survey suggests it could. According to the survey, data and analytics leaders who increased data sharing led teams that were 1.7 times more effective at showing demonstrable, verifiable value to stakeholders.

Get your people on board – Early buy-in from employees, from the conceptualisation to implementation stages, helps to mitigate the scepticism often felt within a business in times of change. As presented within this Siemens Advanta blog, it is important to consider that digital transformation can often be as much a cultural transformation as it is a technical one.

Early engagement of your staff in the journey itself will help determine native digital fluency throughout the business, supporting the identification of internal experts, plus those areas that require future training and development.

These principles are constructed upon time-proven best practice and decades of solution implementation experience, underpinned by common sense. They are designed to directly reduce the risk and effort associated with data-led value enablement.

Embedding these principles supports the goals of early identification of business value based on common and existing data, and minimising enablement cost and business disruption in terms of systems and personnel alike. Consequently, these principles can be directly mapped within a wider strategic digital transformation approach, known as the ‘Digital Core’.

What is digital core?

Digital Core is a term occasionally used in the industry to describe technology platforms and applications that support business transformation, enabling organisations to address the needs of nascent and evolving markets considered within the digital economy.

Central to our Digital Core thesis is the consideration that existing and legacy systems cannot and will not be replaced overnight. Certainly, there will be times when operational systems reach the end of their working life, fail to integrate or even scale, at which point strategic product replacement will lead the way.

However, it is reasonable to assume that the constellation of operational systems in place throughout today’s modern utility landscape is likely to broadly reflect the enterprise environment in operation towards the end of the decade.

Therefore, to our team at Siemens Advanta, the Digital Core represents a mindset and approach, as much as technology and solution.

The Digital Core enables facilitates transformation; its adoption enables businesses and their stakeholders to build upon existing investments and extract data from operational core systems with focussed investment, to create new business value, underpinned with a clear business rationale. This, in essence, is harnessing the data that is being created and stored today throughout your organisation.

Digital core: systematic engagement and analysis

From a methodology and engagement standpoint, the Digital Core requires a baseline of technologies and systems which are strategically relevant over the mid-to-long term for a client. The theory is that each will represent the anchor for digitalisation initiatives over the coming years.

We consider the data from these core systems to be of principle value, as it is likely to be increasingly consistent and even enhanced, throughout a given time horizon, thus worthy of accessing for repetitive re-use.

Analysis of these core systems enables the creation of the MVD baseline, an activity that identifies what data and information exists and documents what is subsequently accessible today from these core systems. This environmental analysis of strategically and operationally relevant systems documents the data landscape and digital maturity of each core system.

Additionally, robust engagement sets out to understand and document the challenges faced by clients. In discussing business pain points and framing strategic and operational hurdles, it is feasible to derive data-driven resolutions in the form of new use cases and applications. Each of these can be subjected to cost-benefit analysis to calculate independent ROI.

Furthermore, this analysis includes consideration of the typical input data expected to bring individual use cases to fruition, tying the value directly back to the enabling, underlying data itself.

A gap analysis follows, assessing generated/accessible data from the business against highlighted use cases and input data. Any significant gaps can be either addressed via business change management to trigger additional data discovery or, where relevant, with targeted access to third party data, such as Metrological data. Armed with this insight, use cases could be reprioritised based on the MVD baseline and cost to supplement or extend. The outcome of this consultative process is to derive a common MVD landscape, which encompasses the following elements:

- MVD baseline – an overview of the data generated within the business from identified key systems, acknowledging which is and is not accessible to the business.

- Business challenges and resolutions – highlighting defined use cases alongside the common data required to enable each.

- Data gap analysis – available data versus use case comparison.

- ROI review – framing cost-benefit of key use cases from existing business data

As a consolidated activity, this gives a robust insight into the digital environment of any client, documenting how current data can address key challenges and create new value when enabled via the digital core.

Digital core: a client-driven solution

The Digital Core is not only a consulting activity but also the provision of a client-orientated solution. Tasked to access the MVD baseline from core business systems, it facilitates the creation of impactful use cases via a reusable and accessible integrated solution.

In creating a common, reusable and accessible data framework or MVD baseline, the intention is to enable client stakeholders to rapidly ideate, test and develop parallel data-led innovations. At every step of the Siemens Advanta Digital Core journey, value is created, either in analysis and understanding or with rapid prototyping and testing of ideas based on common data.

Depending on the respective requirements of each business, the form of the digital core solution will change. This is to balance the need for on-premise versus cloud technologies and for creating a single source of truth, like the master data of the business data versus a reflective data extract from core systems.

Once available, this promotes wider internal access to useful data, away from critical business systems, with governance factored into the solution. Thus, the need to really understand what data you have, where it came from, where it goes, security implications and its quality is satisfied. Such technical considerations will be explored further in a later blog.

As the digitalisation journey progresses, the MVD baseline can be extended with additional, richer data and information, compounding the enabling value of data held within the digital core.

In some regions, such as the UK, there is even a push towards ‘presumed open data' from the energy sector. This involves requiring that utilities, amongst others, reveal data to external parties, with the ambition to foster whole systems thinking and innovation to address sustainability and energy-related challenges.

The digital core methodology and solution accommodates even such a progressive take on data sharing, whilst providing governance and internal value creation simultaneously.

Delivering value from digitalisation should not be held to ransom over big data aspirations. Using a common or emerging MVD baseline to demonstrate quick wins in the form of a Proof of Value and Minimum Viable Products will promote longevity and acceptance of the broader digital transformation initiative.

Streamlining investment to deliver greater returns

According to a Siemens Advanta HBR pulse survey, 80-90% of respondents can’t or don’t accurately measure ROI for digitalisation initiatives. Given this, it is somewhat unsurprising that between 60% and 85% of digital transformation initiatives have failed. You can find more detail in our white paper, Internet of Things: From Buzzword to Business Case.

The paper spells out the direct costs associated with IoT/digitalisation initiatives, including applications, platform/solution, communications and devices/assets. It also quantifies the transition costs that align to the business and its adoption of new technologies.

Transition costs include the processes and tools, skills and personnel development that go alongside change management – all critical factors when considering the true cost of digitalisation.

A realistic ROI assessment will not yield a singular outcome. However, when considering variable uncertainty ranges within the calculation, the credibility of the results increases dramatically, as shown in the white paper.

The ROI analysis can, therefore, be enhanced when adopting a specific lens towards global utilities, offsetting the direct and transition costs against benefit created for the business.

As part of an activity called ‘360 business impact reflection’, analysis considers how data access and new use cases will impact the business. It addresses individual or shared challenges throughout internal departments with, for example, cost savings, efficiency benefits and improved KPI adherence.

This task includes the effort to prioritise and analyse common KPIs consistent with many utilities worldwide, based on the respective organisations. Examples include:

- Planned network interruptions

- Unplanned minutes lost

- Number of faults

- Inspection and maintenance cost

- Network reinforcement and refurbishment

- Asset health

- Customer satisfaction and complaints

- Cost to serve

- Time to connect

- Environmental management

These KPIs align within broad strategic pillars for utilities, which commonly include:

- Delivering a safe and reliable network

- Improving environmental impact

- Improving network connections

- Enhancing customer satisfaction

- Supporting vulnerable customers

360 business impact reflection in action

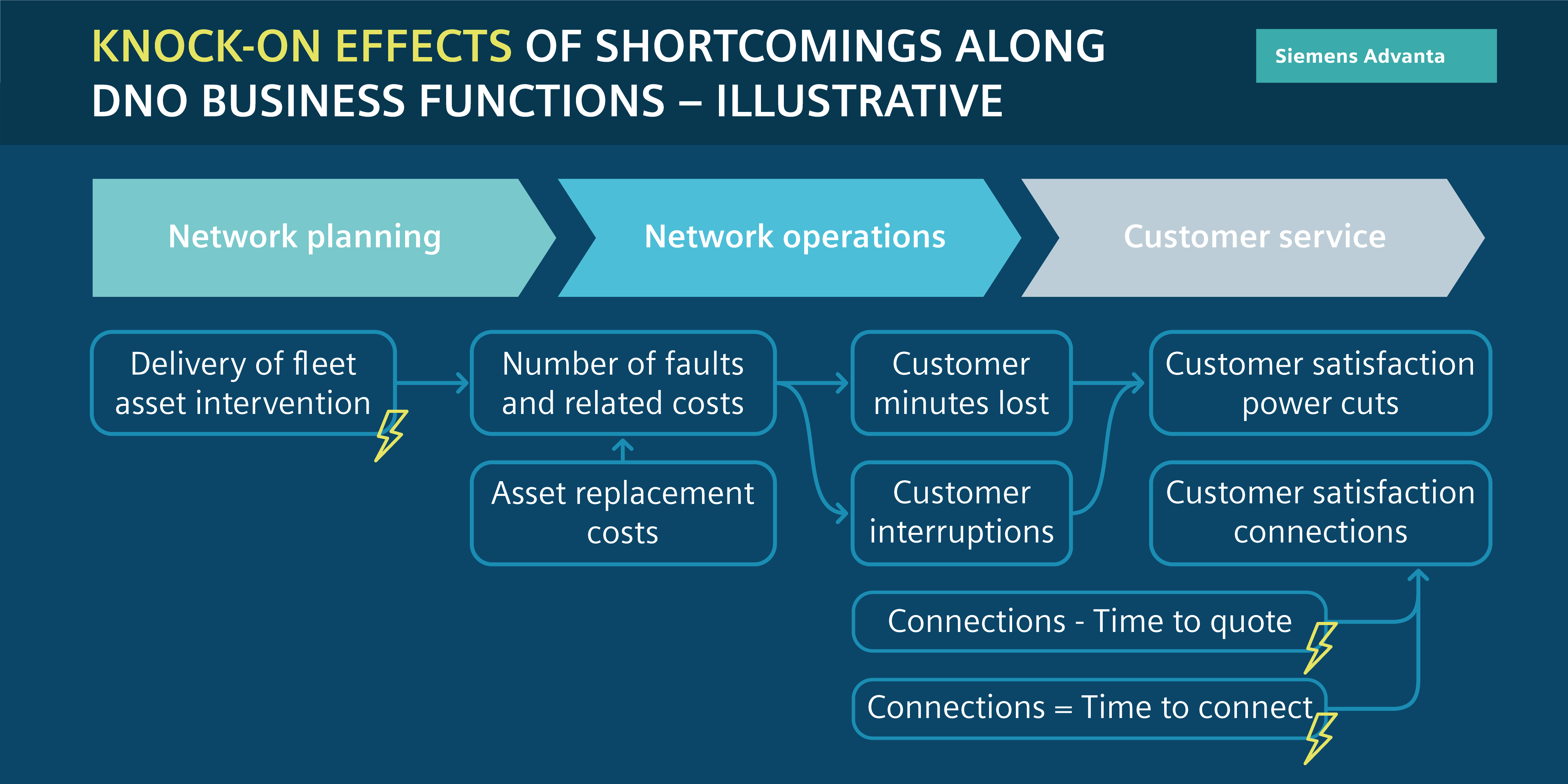

To explore the concept of 360 business impact further, let us take a specific example: heightened vulnerability of network assets due to sub-optimal network planning. In this example we’ll consider three key departments of the utility: 1) network planning, 2) network operations and 3) customer services.

- Suboptimal network planning can intrinsically increase the risk profile of the asset fleet throughout the network. 360 business impact reflection considers the effectiveness of asset intervention programmes, how asset risk is determined and the replacement/upgrade of each asset managed.

- The outcomes of this shortfall roll into network operations. Higher asset risk is likely to increase the number of faults and related costs of the network, potentially decreasing the operational lifetime of fleet assets and in turn increasing asset replacement cost.

- With increased faults come increased outages, impacting the customer in terms of minutes lost and supply interruptions. These factors are likely to come back to the customer services department, which must respond to stakeholders, both customers and regulators, as to the network performance.

- Such topics can additionally be reflected in the time to quote and connect of the connections department.

(Digital Core) Process + Solution = Outcomes

The cause and effect of decisions and activities is a constant within any operational environment and, as noted previously, digitalisation is not a silver bullet. However, what can be provided is richer, more powerful insight, using data from existing systems, manifested within new use cases, to solve current and future business challenges. As an inclusive and accommodating methodology, understanding the specific circumstances of each client, the Siemens Advanta Digital Core ensures a financially appropriate outcome is realised with clear investment rationale.

By linking the enabling and value creation activities, built upon existing client systems, and addressing specific business challenges using current and available data, it drives and unlocks impactful use cases as part of a tailored solution for your business.

Free whitepaper

Discover the Internet of Things and the challenges that need to be solved in a digital transformation. Get insights how to create value when optimizing processes or generating new business models out of data.

Our expert

Eight Key Challenges for Digital Transformation to Succeed

Eight Key Challenges for Digital Transformation to Succeed

According to the Harvard Business Review, Siemens is among the top global players for digital transformation along with firms such as Amazon, Netflix, Microsoft, and Intuit, to name just a few. Since the dawn of the digital age, Siemens has been at the forefront of digital automation, vertical software leadership, and, more recently, the Internet of Things (IoT). This means that as an organization, Siemens offers unique insights into the challenges that need to be met for digital transformation to succeed, because the company already stumbled over several roadblocks itself. If digital transformation strategies are not put in place, or enacted poorly, then companies will fail. After all, around half of Fortune 500 companies have disappeared since 2000. The same fate could befall any organization that fails to meet the challenges for digital transformation today. What are they, and why are some not as obvious as others?

Obvious business challenges of digital transformation

First, it will be best to look at some of the most obvious business challenges with digital transformation. They are a good benchmark of what every organization will need to overcome to succeed in the digital future. They are also a good starting point to think about digital transformation before the less obvious challenges start to become more evident.

One – Developing new services and products

Perhaps the most obvious of all challenges for digital transformation involves identifying new services and products to support a business's core portfolio. New customer demands force businesses to develop new products and services. However, companies often struggle to find the right solutions that fit their original business strategy and product portfolio. To take a highly successful example, Netflix began as a DVD and Blu-ray rental-by-mail firm in 1998, a service it still offers. Netflix's commitment to digital transformation in the 2000s meant it initially offered an online ordering system for its physical products. Soon, however, it had completed its digital transformation into one of the world's most popular digital streaming services, not just offering on-demand access to its customers but producing exclusive content for it as well. New business models that go beyond the traditional core business, such as Anything as a Service (XaaS), can be one digitally enabled evolution for a traditional business. A holistic data strategy can support the evaluation of the value of data for a business and identify new untapped business potentials.

Two – Digitizing internal processes and new tool implementation

Another quite obvious business challenge with digital transformation addresses the goal to optimize internal processes and procedures. While the development of new digital products and services is very much outwardly focused, transforming processes are about focusing on internal structures. In many organizations, this might boil down to adapting internal processes so that they can function in a newly implemented digital environment. This might mean, for example, analyzing where exchanging traditionally used tools to digital ones will work, such as human resources (HR) tools. For instance a digitized self-service portal for booking leave or assigning availability for shifts could make it much easier to track worker numbers in real-time rather than relying on old-fashioned paper-based systems.

Equally, leveraging customer data to simplify and accelerate business processes can help firms to run more efficiently. For example, Artificial Intelligence (AI) systems might be deployed in manufacturing businesses to ensure supply chains are one step ahead of the game. AI-driven sales forecasting might help with inventory and financial planning, but it could also inform buyers that they'll need to order certain components to meet future orders even before they are done deals. In short, process automation is about operating with less wastage and greater efficiency, something that affects every company's bottom line. However, not every process should and can easily be digitalized. The secret lies in identifying the right areas and tools in which digitalization provides value not only to the organization itself but also to its customers.

Digital transformation key challenges that are more hidden

There are also some less obvious challenges organizations need to face today during their digital transformation. Although many digital transformation challenges faced by organizations and their potential solutions are, in fact, relatively clear, some might not be. What are those hidden challenges, and why are they sometimes not so easy to identify within certain organizations?

Three – Developing a holistic digitization strategy and north star

Today, every digital transformation strategy needs to be based on a holistic digital approach that does not play around on the sideline. By adding a 'off-the-shelf' digital offering here or there, some organizations might feel as though they have done enough to adapt to the digital age. However, it is only by adopting a comprehensive strategy that true transformation will be achieved. Of course, any transformation, digital or not needs to fit the overall business strategy. Otherwise, business goals will not be achieved. This doesn't mean that everything other than a root-and-branch adoption of digital technologies will be enough if an organization wants to succeed. This means that its core business, as well as its organizational structures, processes, and technologies, need to be part of the transformation strategy.

Think of it like following the north star in the night sky. Although there might be a lot of change happening around it, progress in one direction is possible by sticking with the fixed point in the distance. This is why a holistic approach is often less obvious to organizations that want to change. Many will try to alter one or two things and question why a more comprehensive approach is needed at all. However, unless digital technologies are deployed throughout the organization, from the business management team to the people and organizational structure as well as the operational processes, competitors are likely to outperform further down the line. In short, for digital transformation to work, it needs to be truly transformative in every aspect.

Four – Gaining the commitment of top leaders

In fairness, digital transformation leadership challenges come in many forms. The most essential one to grasp will be gaining the commitment of business decision-makers to go about transformational change. Unless the management team is on board with a holistic approach to organizational transformation, it will be much harder to achieve the desired outcomes. In other words, the key decision-makers need to be committed to all of the initiatives that will form the digitization strategy. Even more crucial, they'll need to see it as their highest business priority.

For those driving digital transformation from below, keeping the top management on board is vital. Therefore, chief information officers will need to continue extolling the virtues of digital transformation in commercial terms. Once digital transformation begins, there should be no turning back or wavering among the top level of management. Equally, company bosses need to foster enthusiasm among their middle management teams if the project is to come to fruition in a timely manner. Business owners will need to ensure they have the buy-in of lower management levels as well as ordinary employees. Sometimes appointing champions or ambassadors of digital change can make all the difference in ensuring this sort of buy-in occurs.

Think of it like following the north star in the night sky. Although there might be a lot of change happening around it, progress in one direction is possible by sticking with the fixed point in the distance.

Five – Obtaining external capabilities by strengthening your partnerships and ecosystem

The next hidden challenge that needs to be met is how to obtain the external capabilities you'll need for your organizational transformation to succeed by leveraging your partner ecosystem. Some organizations will have some of the digital competencies they will need to transform in-house already. Others won't. Therefore, you need to understand your own core competences first and complete it with strong partnerships afterwards as even the largest organizations cannot do it alone. Regardless of the number of recruits an organization takes on board to complement its current skillset, outside partners will need to be brought in as well. This may mean a transformation in management culture too, of course, if the organization in question is not used to outsourcing some of its key processes. There are alternative strategic approaches some organizations might also like to consider. For example, companies don't always need to outsource to secure the capabilities to strengthen their ecosystem. Instead, they could look at joint ventures with partner businesses or even analyze their options with regards to mergers and acquisitions. If the skills a business needs are already abundant in a competitor, it might be worth considering to adapting it.

Six – Altering employee mindsets and ways of working

Although it is fair to say that systems, processes, and managerial buy-in are all crucial to meeting the challenges of digital transformation, there is something else businesses need to consider: people. After all, it is people who will be at the core of any successful digital transformation exercise. Unless your own staff gets on board with the concept and understands its benefits from a very early stage, it will not be the success it could be. What does this mean in practical terms, though? To begin, education is at the core of explaining why a digital transformation strategy will be better for the strength of the organization as a whole. People may feel threatened by adopting a new way of working or of increasing automation, potentially putting them out of work. However, if they are taught to realize that without a digital transformation process, the business does not have a viable future, then they'll soon come to understand why such change is needed. In other words, they need to realize that digital transformation is in their best interest and beneficial for all stakeholders.

Organizations can create better awareness about digital transformation by being open about the process. Secrecy rarely helps in meeting the challenge of persuading people about this sort of transformation. As transformation plans begin to roll out, organizations will want to alter their employee's mindsets. This won't happen unless staff members feel empowered with the digital tools they're now expected to use. In short, it means investing in high-quality employee training so staff can adapt to the new way of working. In some cases, decentralizing decision-making to a departmental level can help people to feel more in control of the change process. Agile ways of working may be introduced thanks to digital technology, but it may still take a period of adjustment to ensure full commitment. People still often want human interaction when they're at work, so it's important to give employees time to adjust their mindsets and habits. The bottom line is that employee buy-in is crucial. Therefore, without educating your people about the new technologies and processes they'll be expected to use, your transformation simply won't work.

Seven – Keeping hold of the ownership of business digitization

In short, digital transformation needs to be driven by the corporate decision-makers themselves. It is not a project that leaders can fully delegate to their business units, IT department or regions. The responsibility can’t lie with a single department but needs to be realized cross-departmentally to avoid silo thinking, power struggles, following departmental goals and losing the overall picture. The transformation will alter every aspect of the organization, not just specific business areas, products, or functions. Equally, there is no one-size-fits-all transformation process businesses can purchase off-the-peg. Every step along the way needs to be tailored not only to the whole organization involved but also to the individual business. Every business needs to take care of adapting the corporate initiatives to their individual needs.

Eight – Developing an implementable transformation program

Finally, it is insufficient to have a theoretical framework for digital transformation alone. Organizations can plan ahead, but what they'll actually need is something concrete that can be fully implemented. Therefore, a holistic program for digital transformation is needed. A key challenge for all organizations, both large and small, is to have a program that is not only far-reaching but also realistic at the same time. The program needs to be adaptable to any changes in real-world situations. Business priorities might change as the digital transformation program is underway. Setting up trackable key performance indicators (KPIs), overarching goals, and other measures is essential to keep track of progress. It is also fundamental to identify lighthouses, namely already running and successful projects and blueprints as best practices to set an example for all parts of the organization.

Overcoming digital transformation challenges in large and complex organizations

Digital transformation should not be done for its own sake. Organizations that do not follow their business imperatives on their journey will not see successful outcomes. All business transformation projects need to be adapted to their individual organizational needs and digital transformation is no exception to this rule.

Although kicking off a digital journey is unique, the challenges identified above are key to every commercial enterprise and organization when it comes to digital transformation, regardless of its core business. However, some companies will face further challenges specific to their region or sector. Of course, identifying the key obstacles to success is one thing, but doing something about them is another.

The factors that will help large and complex organizations to overcome these challenges are also varied. Key among them is the integrative and multi-dimensional approach that should be taken throughout the organization. This must be based on a holistic strategy, because scratching at the organization’s surface will not be sufficient to drive real change. Accepting that there will be resistance to transformational change, especially at the beginning of the project, will be of huge benefit. Organizations that try to force the pace of change or that make too many demands of employees tend to suffer.

That is not to say that digital transformation projects should not be ambitious. The transformation will require organizations to challenge every aspect of their processes, technologies, and structure. The key is momentum. Once change is happening, keep the ball rolling and don't let it stop. You don't need a wrecking ball approach, however. Think big but start small. All organizations will find there is better buy-in from stakeholders once the proof of concept surrounding the strategy has been established. Therefore, even small early wins can have a big impact on change down the line. In many situations, a strong partner company is all that is needed to tackle the initial challenges, as well as the harder ones that businesses will sometimes face as the pace of change picks up.

Our expert

Author

From complicated to complex: how digitalization in transforming our world

Tune in and find out what the future holds for us!

Aymeric Sarrazin and Beverly Rider will share their vision of the journey from a complicated to a complex world.

Find us also on your favorite Podcast APP:

Apple Podcast, Google Podcast, Siemens.fm,

Stitcher, Spotify (log in to listen on desktop)

How Digital Technology Enables Sustainable Energy Use

How Digital Technology Enables Sustainable Energy Use

Listen to the blog here:

From traditional industrial technology, such as carbon-neutral synthetic eFuel to an increase in distributed cloud computing, innovators are leading the way to a more sustainable world, and they’re showing huge potential to remove carbon dioxide from the atmosphere measured by the gigaton. Advances in cloud technology alone could remove 1.6 gigatons of CO2 from current emissions.

With everyone from small and medium enterprises, corporate giants to national and local governments committed to reducing emissions, both conventional and digital technologies continue to play a crucial part in developing strategies that offer a sustainable future.

Nevertheless conventional technologies are increasingly being augmented and aided by digital solutions that enable smart interconnections to reduce emissions through digitalization and industrial Internet of Things (IIoT).

Let’s look at a few examples across different sectors to examine the potential of digitalization, driven by the need to curb energy consumption.

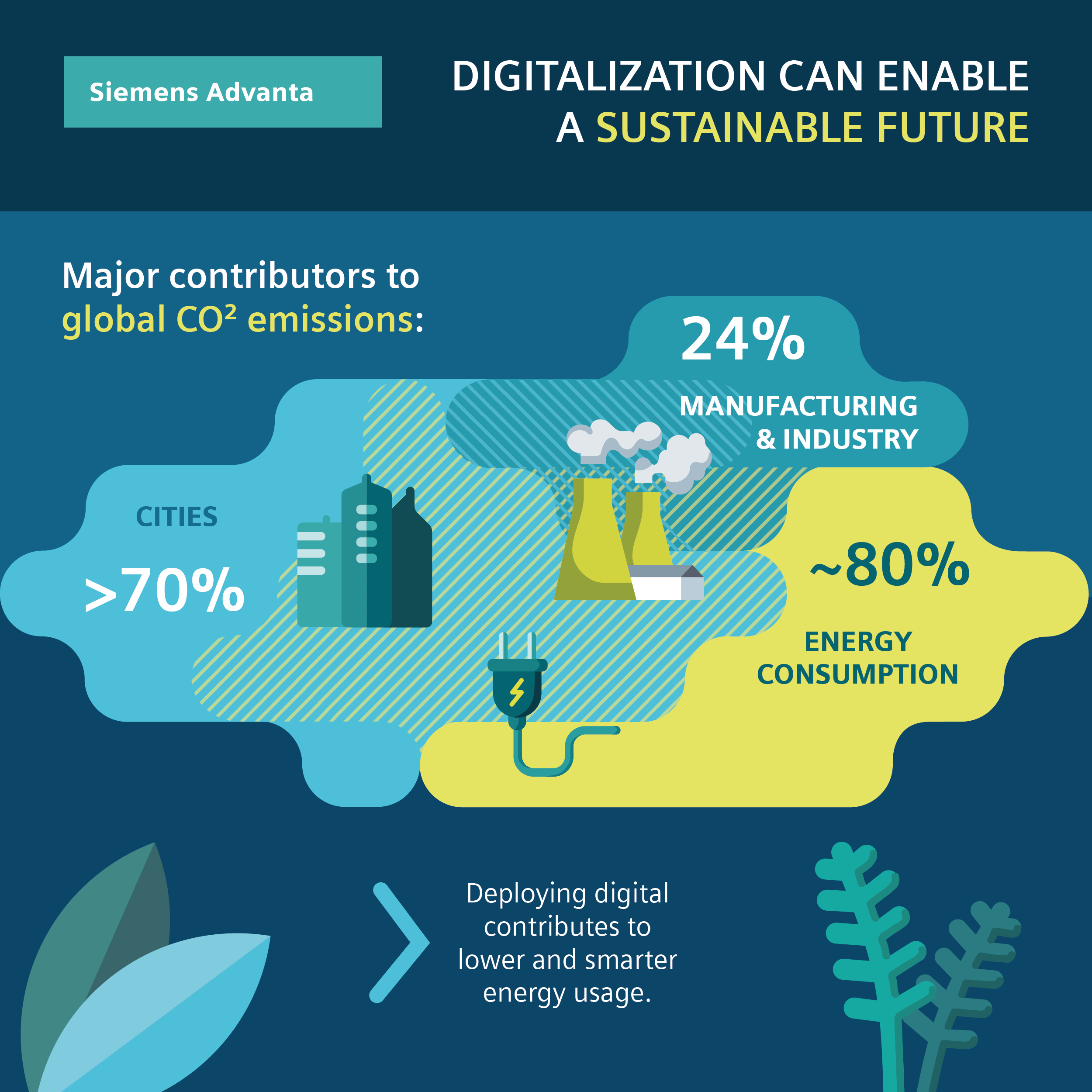

Smart cities: energy savings through digitalization

Cities account for the majority of energy demand and resulting CO2 emissions; more than half the world’s population is urban, accounting for 78% of the world’s energy consumption and creating over 70% of all CO2 emissions. Whilst there is clearly some overlap between overall urban emissions and emissions from other sectors such as manufacturing and transport, buildings represent the largest portion of urban emissions, with non-residential buildings being 40% more energy-intensive than residential dwellings.

The heating, cooling and ventilation elements of buildings account for the lion’s share of their energy demand. In addition, energy-intensive embodied-carbon materials such as concrete, steel and glass often used in the construction of high-density urban buildings account for one-quarter of all buildings emissions.

To make cities smart – in other words, to create systemic efficiency for a sustainable, low-CO2 future – we have to look at the city as an ecosystem of urban features that is essentially one big energy demand center, and then figure out how to get those elements talking to one another.

How do you create scalable interconnections between buildings, energy infrastructure and transport?

Guidance on how cities can achieve environmental targets is key. Siemens has developed the City Performance Tool, a tool that can give an indication on how each infrastructure-related decision might influence employment and growth in the infrastructure sector.

“By leveraging the power of life cycle engineering and data analytics,” says Klaus Heidinger, Head of Sustainable City Solutions at Siemens Advanta, “the City Performance Tool helps to identify the best technologies in the energy, buildings and transport sectors for reducing greenhouse gas (GHG) emissions, improving air quality and creating new jobs in the local economy. The tool,” he goes on to say, “compares the performance of over 70 technologies and generates a shortlist of the most cost-effective solutions to help cities meet their environmental targets and has been validated by the world’s best academic institutes such as MIT, TU Berlin and London School of Economics.”

Arup and Siemens studied five cities across Europe to develop a methodology for demonstrating the long-term benefits of grid digitalization. In London, for example, where the grid operates close to capacity, they found almost half of its substations are under stress. Digitalization allows for smart systems like flexible AC transmission so that operators can squeeze more capacity out of the existing infrastructure without the need for further investment.

When coupled with digital measures that address systemic efficiency – such as Siemens’ joint venture with Vienna’s network operator – digitalization can help create connected elements of a smart energy infrastructure. These will help reduce emissions by modelling energy demand across the world’s urban areas. Vienna alone cannot solve the world’s problems, but as an example of digital measures that can be scaled up, it has huge potential.

Cities become smart cities when they offer interconnections that enable different segments of a city to communicate with each other for maximum efficiency in energy production, consumption and cooperation. The potential is huge; in Europe alone, the decarbonization of cities could cut CO2 emissions by an estimated 243 megatons. That’s the equivalent of permanently removing 188 aircrafts from the world’s commercial jet fleet, or nearly half of Lufthansa’s entire Airbus passenger fleet.

Manufacturing & industrial sector: better energy utilization thanks to lean manufacturing and digitalization

The worldwide industrial sector in isolation accounts for 37% of global energy use and 24% of all global emissions. Of course, the sector is also responsible for a proportion of city emissions (above), because some manufacturing and industry is sited in urban industrial zones and demands energy. However, to align with a sustainable development scenario (SDS), regardless of its siting, the sector’s emissions must fall by 1.2% annually, to 7.4GtCO2 by 2030.

Nonetheless, how can we go about reducing that impact?

Digitalization can help manufacturing and industry become smarter and more sustainable through better capture and use of data, more efficient energy use, and tighter resource management. Digitalization helps with real-time collection of data to identify problems that cause waste or unnecessary energy loss.

Spanish automotive supplier Gestamp worked with Siemens to save energy through data analytics. Siemens’ cloud-based application collects data every one or two seconds from plant machinery in individual production plants maintained by Gestamp around the world, from devices that collect around 800 million data points daily. This gives the company access to data on electricity and gas consumption in real time.

Easily scalable IIoT manufacturing solutions such as these can make manufacturing processes smarter, more reliable, more sustainable, and more likely to contribute towards decarbonization goals.

As a result of its digitalization, in its first year with the application, Gestamp’s improvements led to energy savings of 50 gigawatt-hours of energy. With over 15 networked production plants, those savings grew by 55 gigawatt-hours in its second year. With additional new plants opening in China, that are networked to the cloud-based application, more savings can be made.

Thanks to reduced energy consumption, the company has been able to lower its CO2 emissions by 15%. In 2016, Gestamp emitted 14,000 fewer tonnes of CO2 than the previous year, and by 2017, it had saved a massive 16,000 tonnes. That’s the equivalent of taking approximately 3,200 cars off the road.

Each 1-percentage-point reduction in the emissions of the global industrial sector, as a proportion of global GHG emissions represents a potential saving of around 350 megatons of CO2.

Grid loss: saving CO2 through digitalization

Currently, 80% of G20 carbon dioxide emissions come from energy consumption. As discussed above, cities – particularly their buildings and the manufacturing and industrial sites they host – are responsible for a large tranche of that consumption. When coupled with the fact that 60% of the way we handle energy is inefficient, the scale of the challenge can sometimes seem daunting.

On the contrary, that also means that the potential for savings through digitalization is huge. Deploying Digital can help save up to 65% in Energy Use, depending on what area you look at.

The global Distributed Energy Resource (DER) capacity is expected to more than double in the next ten years. With the transformation of our energy system into a decentralized system requiring constant balancing with minimal baseload, this will significantly increase the complexity of the distribution grid.

How can we overcome this?

Smart meters, for example, represent a scalable digital technology that provides real-time information to energy providers and consumers, reducing emissions as well as energy costs. With a digitalized grid, if you need to charge your EV, you can schedule it to demand energy when supply is at its most plentiful and affordable, with the maximum component of clean and renewable energy.

Siemens recently supported a European utility to determine the aggregated load profiles for individual low voltage stations. This consisted of a digital twin of the low-voltage grid, which allowed the utility to simulate all possible network states caused by the volatility of DER and electric vehicle (EV) charging stations. Armed with that data, digitalization could offer additional levels of freedom for distribution grid operators to maximize existing network usage and become proactive in managing DERs.

The World Economic Forum (WEF) estimates that 15.8 billion tonnes of net avoided CO2 emissions could be achieved in the electricity sector by enabling the integration of additional renewable capacity through digitalization and smart grid technology. The benefits don’t end there; utilities that have undergone digital transformations have already seen revenues grow by over 4% in the first two or three years, jumping to as much as 25% in the longer term.

WEF also believes that energy companies could unlock up to USD 1.3tr in value by 2025 by taking advantage of the data-driven decision making, as well as the active asset and resource intelligence that scalable digitalization offers.

Scalable digitalization is powering a sustainable & networked energy mix

Digitalization is providing the energy sector with opportunities that have never existed before; opportunities for minimizing emissions whilst maximizing efficiency in scalable solutions, all leading to a more sustainable future that benefits everybody.

It’s time to move to a digitalized future that can truly deliver the GHG emissions savings we need and set us on a path to true sustainability. With these three scalable examples alone, digitalization offers the potential to save CO2 emissions measured in the tens of gigatons.

Accelerating your digital transformation

Siemens Xcelerator is our open digital business platform and marketplace enabling efficiency, resiliency, flexibility, experience, and sustainability.

Making our customer’s digital transformation faster, easier and at scale.

Free whitepaper

In this whitepaper you will learn how to combine technology and strategy in a unique way based on actual project experience, see a breakdown of the key enablers, and explore the impressive best practice of “The Red Sea Project & AMAALA”!

Our expert

How Will Technologies Shape a Bright Digital Future?

Society 5.0: How will Technologies Shape a Bright Digital Future?

Listen to the blog here:

Dr. Oliver Elbracht (Siemens Advanta): The Society 5.0 concept emerged from the Information Society and was initially expounded in 2016 in the Far East. In Japan, the new societal model was first defined to mean a human-centered approach to the ever-growing take-up of technology. Also called ‘super-smart society’, it aims to balance economic advancement more widely across society, for example, as well as create an opportunity to think about how certain social challenges can be resolved by digital technologies such as big data, Artificial Intelligence (AI), the Internet of Things (IoT) and robotics.

Having a closer look at the Middle East region, digital transformation programs are already in full swing: from oil fields, to manufacturing, to city infrastructure. Leaders in the region are aware of the societal and business demands and are already addressing the emerging challenges to shape the transition into the future.

I’m Oliver Elbracht, Managing Director for Siemens Advanta in the Middle East, and in the context of the event Transformena 2021 in April this year, I had the honor to sit down with several remarkable leaders from corporations in the Middle East to discuss how technology is creating a better tomorrow. Below you can find an extract from my discussion with Neetan Chopra, the CTO of Dubai Holding, Ahmad Aalem, the former Head of Strategy at The Red Sea Development Company, and Abdullah Albalushi, who holds the role of Board Advisor at The Zubair Corporation LLC in Oman.

The answers of these great panelists were certainly quite revealing, as I'm sure you'll agree with this insightful discussion.

Dr. Oliver Elbracht (Siemens Advanta): Ahmad, is focusing solely on technological solutions and their implementation enough to achieve the Society 5.0 concept?

Ahmad Aalem (The Red Sea Development Company): The Red Sea Development project is focused on creating a luxury tourism destination, that is based on the sustainable concept of regenerative tourism through a twin approach of person-centered and technological change. We are no longer settling for simply protecting and preserving the environment. We aim to enhance it. Indeed, we are committed to enhancing Saudi Arabia's natural ecosystem by 30 percent over the next 20 years. Crucially, it is technology that will enable this link between tourism, the environment and sustainability. Construction in sensitive areas may mean a modular construction method with manufacturing on-site, which needs to be sustainable, but this means you need people on board with the entire concept, not just the technology itself.

Dr. Oliver Elbracht (Siemens Advanta): How can technologies benefit people within the concept of Society 5.0?

Ahmad Aalem (The Red Sea Development Company): A good example would be our adoption of a smart destination platform, that allows guests and workers to monitor the environmental conservation enhancement across our lagoons – up to 2,400 square km of water. One of the best examples of the 52 smart technologies we've adopted is a wearable device for employees and vehicles to help maintain the balance between the environment and efficient construction. This device enhances employee welfare, too, by making sure they are supported by improved security measures, for example, by allowing an SOS signal to be sent. For now, AI and smart tech deployment is focused on our employees as we're in the construction phase, but in the future, it will center on a seamless visitor experience.

Dr. Oliver Elbracht (Siemens Advanta): The progress you're making building this unique destination truly amazes me. Now, from a smart tourist destination in Saudia Arabia to a smart city in the UAE. How does smart technology contribute to Dubai's objective to be the smartest and happiest city in the world?

Neetan Chopra (Dubai Holding): From Dubai Holding's perspective, there are two main actions. Firstly, we want to be in the arena, not on the sidelines, getting stuff done. We take action in transformation, innovation, and technology. Secondly, we support the technological ecosystem, which is enabling innovation and transformation. Further, when it comes to digitalization, you need to create magical, memorable experiences for customers – and employees alike. That is critical for the whole transformation journey. You can't be digital in the front-facing part of your business but at the same time keep your back office analogue. That doesn't give you true transformation. Additionally, we've found that investing in new business models as well as forging symbiotic relationships between start-ups and enterprises is crucial.

Dr. Oliver Elbracht (Siemens Advanta): How are businesses using digitization to manage large numbers of employees across various industries?

Neetan Chopra (Dubai Holding): Forward-looking organizations recognize that you can't do digital or transformational change without including your employees. It's critical! If you only focus on the customer receiving great digital experiences but forget about your employees that’s not a true digital transformation. The digital platform we have adopted at Dubai Holding connects all 20,000 employees. This offers them the same level of digital experience as our customers expect.

Dr. Oliver Elbracht (Siemens Advanta): The scope, scale, and economic impact of technology have been rapidly expanding in the Middle East. How have forward-thinking corporations integrated technologies in the region?

Abdullah Albalushi (The Zubair Corporation): The Zubair Corporation is one of the longest established business conglomerates in Oman. It started its business back in 1969. Of course, the business landscape at that time demanded a very different way of doing things. Then, focusing on building the infrastructure of the country in cooperation with the government was the priority. Only a few corporations were able to meet this challenge. Those which, like The Zubair Corporation, were widely perceived to be part of government and, consequently, to have a lot of social responsibility. The government's 2040 vision expects Omani corporations to continue to meet these social demands in the country, so it will shape our future as well as our past.

Dr. Oliver Elbracht (Siemens Advanta): What is your approach to future digitization as Society 5.0 becomes an increasingly felt reality?

Abdullah Albalushi (The Zubair Corporation): We inherited various complex legacy systems, often by acquiring and merging with other companies. Therefore, after 50 years of business a check was needed to re-energize the company. We found that there was a big gap with what the younger generation expects, especially with mobile and digital technology. Given that we had historically dealt directly with the government, we didn't always need any of these technologies. Due to the Covid-19 pandemic, everything moved to digital, causing business and social challenges for us. In 2019, we conducted an operational review. Based on that, we developed a digital transformation strategy. We entrusted Siemens Advanta to be our partner in the assessment of our digital strategy, and we are now 50 percent on the way down the road to delivering it. As others have said, the human element in this is creating the biggest challenges, but it also affords us the biggest opportunities. We want to create a truly human-centered ecosystem where all our business units will operate on a single platform, the foundation to innovate and shine.

Dr. Oliver Elbracht (Siemens Advanta): It has been an exciting journey you have been on – not only within Zubair but really for the Omani nation.

I'd love to continue this to experience how you and all of your corporations are making a difference to Middle East societies within the contexts of Society 5.0. I'm excited to see how the Middle East will continue to develop this human-centered, technology-based society in the years and decades to come. It’s fascinating what the upcoming decades will bring and I'm convinced that we can foster innovation that will create a bright future for us and for future generations.

Thank you very much all of you for joining this discussion.

Interested in watching the full dialog? Click here to watch the recording of the panel discussion: Society 5.0 – The Big Social Transformation.

Free whitepaper

The Oil & Gas industry across the globe is facing a number of macro challenges. Several companies are banking on digital transformation in upstream to reduce the operating cost of fields making it viable to operate existing fields beyond their expected lifetime and explore small fields that were till now considered unviable. Download our whitepaper to learn more about tailwinds in upstream digitalization and how to leverage its full potentials.

Our expert

Author

IoT – Driving sustainable Transformation of Urban Environments

Tune in and find out what the future holds for us!

Our guests Dave Hopping and Jeremy M. Goldberg will share their vision on smart cities and digitalization and give insights on how our future will look like.

Find us also on your favorite Podcast APP:

Apple Podcast, Google Podcast, Siemens.fm,

Stitcher, Spotify (log in to listen on desktop)

Digital Twins to Decarbonize Energy Systems

6 Success Factors for Using Digital Twins to Decarbonize Energy Systems

Listen to the blog here:

Let's face it – the world needs to overcome a big challenge with regards to energy: After all, the energy consumption of cities and industries is ever-growing. According to World Bank data from 2019, the proportion of the global population that resides outside of cities and towns has fallen by two-thirds compared to the start of the 1960s. At the same time, academic studies have noted that urban areas account for about three-quarters of global energy use, something that will undoubtedly cause a problem for ongoing sustainability efforts.

Even with more and more green energy sources coming online with every passing month, there is still an extensive challenge to lower carbon dioxide levels in the atmosphere and for the nations of the world to meet their Paris Accord climate change commitments. Many businesses have committed themselves to lowering their carbon footprints to meet regulations and cover new customer demands. Siemens, for instance, was actually the first DAX company to commit on carbon neutrality by 2030 and reduced emissions already by 54% since the start of the program. Consumers increasingly turn to companies that focus on sustainable energy generation and consumption and realize that a profitable future is only possible in a sustainable world. Either way, I already see a world in which decarbonization is considered to be of huge importance in the urban realm. However, many companies still lack a holistic approach to decarbonize their energy systems.

In this article, I will emphasize the relevance of decarbonization for the energy sector and the related energy-intensive industries as well as for sustainable urbanity. Then let me show why digital twins should have a part to play in any decarbonization roadmap. Finally, I will share six identified principal success factors on how to apply digital twins to decarbonize energy systems.

1. Energy is at the heart of the green revolution

Sustainable energy use is at the heart of the fight against climate change, as energy generation is responsible for a huge amount of carbon dioxide (CO2) and other greenhouse gases that get emitted into the atmosphere each year. Only for the purpose of illustration, according to the Energy Information Administration (EIA), electrical generation accounted for some 4.13 trillion kilowatt-hours (kWh) of energy in 2019 in the United States alone. The EIA estimates that some 1.72 billion metric tons of CO2 was released into the atmosphere as a result of all energy sources. To put it simply, that's approximately 0.92 pounds of CO2 emissions per kWh!

Numerous decarbonization trends, such as the switch to biofuels from fossil-derived ones, already try to tackle that problem today. Others include the increasing use of wind energy, both on and off-shore, as well as the development of hydrogen-based fuel cells, or the roll-out of carbon capture and storage (CCS) technologies. These truly are groundbreaking times for decarbonization!