Navigating Change: Manufacturing's Digital Journey

Navigating Change: Manufacturing's Digital Journey

Change is no longer just an occasional challenge for the global manufacturing industry – it has become a constant force. Today, manufacturers are facing a perfect storm of pressures that are reshaping how they operate and innovate. The industry is undergoing a seismic shift, driven by a combination of technological advances, increasing competitive pressure from emerging challengers, and global economic factors that can no longer be ignored.

Technological breakthroughs like Artificial Intelligence (AI), digital twins, and 3D manufacturing are fundamentally transforming production processes and business models. Meanwhile, new competitors are catching up fast. These upstarts are achieving near-equal levels of quality while demonstrating greater agility and innovation, making it harder for established manufacturers to maintain their edge. At the same time, labor shortages, inflation, and slowing economic growth are further compounding the complexity of operating in today’s global market.

To address these mounting challenges, manufacturing organizations are turning to the Industrial Internet of Things (IIoT) as a vital component of their strategy. IIoT offers a path forward by unlocking new efficiencies, enabling real-time insights, and creating opportunities for predictive maintenance. It helps companies do more with less. Additionally, the pressure to meet sustainability standards and increase transparency in operations only adds to the urgency to adopt IIoT solutions.

For many manufacturers, successfully leveraging IIoT is no longer optional – it is crucial to staying competitive. By deploying IIoT solutions, companies can increase operational efficiency, improve customer engagement, and gain critical business intelligence that allows for more informed decision-making. However, despite these potential gains, successfully implementing IIoT is a complex endeavor.

While some companies opt for ready-made solutions, an increasing number are developing proprietary IIoT platforms tailored to their specific needs. This approach offers numerous advantages:

- Tailored systems that integrate seamlessly with existing workflows

- Reduced reliance on third-party vendors, lowering operational costs

- The ability to refine platforms based on real-time user feedback, maximizing ROI

However, developing a bespoke IIoT solution also presents significant challenges. From integrating diverse technologies to ensuring data security and managing scalability, the road to success is paved with obstacles. Even more crucially, without a clear strategy and robust planning, companies risk turning these opportunities into pitfalls. Misaligning technology with actual work processes, underestimating the complexity of implementation, or failing to engage employees throughout the process can prevent businesses from realizing the full potential of their IIoT investments.

This is where integrated change management becomes indispensable. It’s not just about managing the technical side of IIoT deployment; it’s about aligning people, processes, and technology to ensure that the transformation delivers its intended benefits. Change management ensures that every layer of the organization – from leadership to the shop floor – embraces the shift, ultimately enabling businesses to turn challenges into competitive advantages.

Transformation and change: two sides of the same coin

Often looked at as the "soft and fluffy stuff," Change Management is also a technical discipline – reliant on fact-based research, analysis, and strategic thinking aiming at guiding an organization to sustainably introduce changes supported by the workforce. Change Management is essential for many reasons: minimizing disruptions, maximizing employee buy-in, and organizing training and development.

Bringing IIoT into any manufacturing organization requires both a shift in technology and a shift in mindset especially in relation to ‘how things were always done.’ “When organizations focus solely on the technical or operational aspects of a change initiative, they risk encountering substantial resistance and a lack of employee buy-in. This may also result in increased turnover, especially of key people.

In addition to focusing on raising awareness, acceptance and commitment of the workforce relating to changes, Change Management also works very closely with the project, or in the case of large digital transformations, the Transformation Management team. This integrated approach is essential for successful and sustainable implementation. While the Transformation Management team is planning and managing the different work streams of a project, Change Management generates valuable input for when and where those plans need to be adjusted for the organization to follow the changes and generate the expected benefits.

To sum it up, a successful Change Management program requires the acceptance of three factors:

- It is Integrated. Change Management oversees the technology and people involved in the transformation throughout the digital journey – from conception to implementation – and is connected to the Transformation Management team.

- It is Equal. Change Management is often introduced as an afterthought and is limited to communication and training measures. Doing so reduces the effectiveness of Change Management tremendously. Its contributions must be treated equally to those of project management or solution development.

- It is Iterative. Change Management anticipates and adapts to volatile and uncertain situations. “An iterative approach corresponds to developing flexible strategies and plans, and continuously adapting them while already implementing them. This contrasts with a traditional approach that would involve setting fixed goals, detailed upfront planning and rigorous implementation towards a fixed target state.

How to do it right: learn from our experiences

“The reality is that the biggest reason [I] IoT-led changes fail is the inability to reach adoption in core teams and via key stakeholders. With IoT in particular, adoption issues stem from the organizational tendency to force people and processes to accommodate a new technology rather than figure out how the tech will add value.”

A simple example is the issues that could arise if an organization forgets that there are at least five different demographic groups in the workforce right now. From the Silent Generation (1928-1945) to the Baby Boomers (1946-1964), to Generation X (1965-1980), to Generation Y/Millennials (1981-1996), to Generation Z (1997-2010) – each of these groups learn and accept technology at a different pace.

As our colleague Britta Stutzman has written, “Successful Change Management boils down to understanding and relying on the diversity of our workforce; our job is to make sure we know as best as possible what keeps our employees motivated, how they like to learn and adapt to changes and finally what makes them engage in their job.”

But how do you create a transformation program in the right way to avoid the big risk of not having buy-in from the workforce? From our own experience, there are some aspects that contribute to a successful implementation.

- Question if IoT is the right thing to do and how it helps: This might sound surprising, but what we encounter quite often is a situation where the solution is already decided, but the problem that it is supposed to solve, is still unknown. We know that everyone is eager to start and see the first features deployed, but not having clarity on why an IoT platform must be introduced and what should be achieved by it, will fall on the project’s feet later.

- Design the IoT platform based on user feedback: Allowing those affected by the change to contribute to the solution significantly reduces implementation efforts. The people who will work with the IoT platform every day know best what features they need to achieve the expected benefits. This should also not be a one-time query at the beginning, but a continuous feedback collection throughout the rollout. Every deployment of new features will generate waves of valuable input influencing the course and outcomes of the project. Highly influential individuals must be identified and engaged early to minimize change resistance and develop influential change promoters.

- Give clarity on how the IoT platform should be used: While it is always good to leave room for people to come up with their own ideas on how to make use of a solution, IoT platforms are very complex and for them to bring benefits, many different parties have to work together perfectly (e.g., to have correct data, actions can be triggered based on detected patterns). In one of our past projects, the client decided to forgo the focus groups and collaborative workshops on a new solution to let the workers show creativity in adjusting to the new tools. The workers did not have enough time to adjust to the changes causing frustration. Ultimately, the approach did not succeed, and the leaders realized that interviewing employees would provide the input to make the necessary changes.

Changing for tomorrow’s manufacturing success

Despite all the mentioned hurdles and risks associated with introducing an IoT Platform into a manufacturing setup, there is hardly a way around it for organizations that want to be prepared for the future. Fundamental changes in digitalization, automation, and demography need to be addressed proactively by any player in the manufacturing industry who strives to compete in the long run.

By opting to take the proprietary approach to IIoT, manufacturers can focus on both technology and employee acceptance of digitalization. The journey to developing a proprietary IIoT platform, despite its high investment and associated risks, underscores the necessity for strategic and early implementation of integrated Change Management. Success depends on the people within the manufacturing organization believing in, accepting, and driving the changes necessary for a full organizational transformation and manufacturing optimization.

Our contributors

34 Digital Transformation Statistics For 2024 (digital-adoption.com)

Four Key Challenges for IoT Implementation – and How You Can Overcome Them (siemens-advanta.com)

How IoT Is Transforming The Manufacturing Industry (forbes.com)

Improving Operational Efficiency with Industrial IoT: Part 1 – IIoT World (iiot-world.com)

Industrial Internet Of Things Benefits, 2024 Trends, Examples & Challenges | Matterport

IoT in Manufacturing: Applications, Technologies & Examples (itransition.com)

Key Steps to Digital Transformation in Manufacturing: Cherry Bekaert (cbh.com)

Leading the 6-Generation Workforce (hbr.org)

leveraging-industrial-iot-and-advanced-technologies-for-digital-transformation.pdf (mckinsey.com)

Making the IIoT promise real | Whitepaper | Genpact

Manufacturing Optimization – The Paradigm Shift to A Smarter System – IIoT World (iiot-world.com)

successfuldigitaltransformationwhitepaperbysiemensiotservices.pdf

Without Change Management, IoT has no chance - Software AG | Software AG

Author

Accelerating the Future: Strategic Pathways for Emerging Battery Cell Manufacturers

Accelerating the Future: Strategic Pathways for Emerging Battery Cell Manufacturers

Emerging manufacturers face immense pressure from EV makers, investors, and fierce competition amidst market volatility. The rapidly growing battery cell market demands speed and scalability. Those who can quickly ramp up gigafactories will lead the future of energy and transportation.

Speed and Scale – High Pressure on Emerging Battery Cell Manufacturers

The battery cell market is gaining significant traction, presenting a booming opportunity for emerging manufacturers. To capitalize on this growth, these manufacturers must prioritize innovation and speed while navigating a complex landscape to dominate the rapidly evolving electric vehicle (EV) market in the long-term. They face numerous challenges: EV makers demand swift, reliable supply chains and high-performance batteries, investors seek rapid returns and high multipliers, and there is fierce competition from established players with advanced technologies and large-scale production capabilities. Market volatility further complicates the scene, with EV demand projections for 2024 falling short, creating uncertainty through 2030. In this high-stakes environment, the ramp-up of gigafactories is crucial, as the ability to scale quickly has become a decisive factor for new manufacturers determined to lead the future of energy and transportation.

Why Speed is King – Addressing Triangular Pressures in a Volatile Market

The global EV market, valued at USD 388.1 billion in 2023, is projected to reach USD 951.9 billion by 2030 with a CAGR of 13.7%. Despite this, current delays in meeting the 2024 forecast create a volatile market. S&P Global reports that the anticipated EV demand boom for 2024 hasn't materialized, resulting in uncertain projections for 2030 growth. With global EV sales projected to grow by 36% in 2024, down from 62% in 2023, battery cell manufacturers face pressure to adapt. Economic challenges, including high interest rates in Europe and the US and a saturated Chinese market, contribute to this slowdown. Manufacturers must navigate tensions between EV makers, investors, government requirements, and industry players, showcasing their adaptability in a rapidly changing market.

1. Pressure from EV Manufacturers

EV manufacturers stress the need for quick, reliable supply chains, often setting strict deadlines for battery cell providers. Contracts typically include rigorous schedules, with delays leading to financial penalties and reputational damage. The demand for high-energy-density, fast-charging batteries in short development cycles adds additional pressure. Manufacturers must produce lighter batteries with shorter charging times, extended ranges, and reduced carbon footprints, all while meeting high-quality standards. The push for efficiency and excellence in production and quality underscores the intense demands on the EV supply chain.

2. Investor and Government Expectations

Battery cell manufacturers also face significant pressure from investors and competition for government support. Investors expect rapid production scaling within 3-5 years, demanding quick gains and substantial profits. This forces manufacturers to prioritize speed, efficiency, and cost-effectiveness. The need for considerable funding to scale up adds further pressure, requiring strong growth potential and adherence to demanding schedules. Competition for government incentives like tax breaks, grants, and subsidies is fierce. Emerging manufacturers must swiftly adapt strategies to meet eligibility criteria and align with investor and government demands to secure support.

3. Competition from Established Players

Leading companies dominate the battery cell manufacturing market with efficient, large-scale production facilities, setting high capacity and efficiency benchmarks. They use advanced techniques and innovative technology to produce high-quality batteries at lower costs, creating a cost-competitive advantage. This pressures other manufacturers to scale up rapidly while keeping costs low. To stay competitive, new battery cell manufacturers must streamline and accelerate their production processes to reduce costs without compromising quality.

Considering the triangular pressure, the role of gigafactories becomes critical in addressing the industry's demands for speed and scale. These production facilities are designed to meet the high-volume needs of the EV market, promising swift and efficient battery cell manufacturing to keep up with the fast-paced growth and innovation. Gigafactories, with their capability to ramp up production quickly, offer a strategic solution for emerging manufacturers to tackle the pressures of rapid scaling and market volatility.

Gigafactory Hurdles – Fast Ramp-Up and Scaling Challenges

Building a gigafactory and scaling up production involves overcoming intricate challenges. Emerging battery cell manufacturers must adeptly navigate each stage to achieve large-scale sustainable manufacturing.

1. Strategy & Setup

The success of a gigafactory depends on thorough strategic planning and meticulous operations setup. Analyzing target customer adoption rates and battery cell demand is crucial to accurately predicting market demand. This ensures that the factory's strategy aligns with future needs. Securing adequate funding is equally important, as large-scale projects and expansions require significant financial resources to support construction and operations.

2. Product Design

Emerging battery cell manufacturers must balance advanced materials and innovative designs with cost constraints. This requires continuous innovation to maintain economic viability while optimizing energy density and thermal management to maximize storage capacity and minimize size and weight. These efforts align with Design for X (DfX) principles, emphasizing manufacturability, cost-efficiency, and sustainability. Ensuring cell safety and stability prevents risks such as overheating or short circuits. Additionally, achieving consistent performance over numerous charge and discharge cycles is vital for longevity.

3. Factory Design & Planning

Securing an optimal location requires a balance between proximity to raw materials, market access, and logistical efficiency. Access to green energy sources is increasingly important to enhance the sustainability of the batteries. This directly impacts the facility's operational efficiency and cost-effectiveness by reducing transportation costs, ensuring reliable supply chains, and lowering energy expenses. Additionally, creating a scalable and adaptable layout is crucial for responding flexibly to market changes and accommodating future technological advancements and shifts in demand, ensuring the facility remains competitive and efficient.

4. Build, Commission & Ramp-Up

The build, commission, and ramp-up phase involves several critical tasks. Integrating and stabilizing new equipment requires meticulous oversight and collaboration with machine builders to ensure efficient manufacturing processes and prevent delays and cost overruns. Hiring and training a skilled workforce is equally important, as advanced manufacturing processes demand highly qualified employees to manage sophisticated systems and ensure smooth operations.

5. Operate

Once operational, a gigafactory must manage ongoing complexities. Handling maturing processes is a significant task, with errors occurring from electrode production to module packing, often making stacking a bottleneck process that requires continuous improvement and careful monitoring. Scaling up production while ensuring process stability is crucial. As the gigafactory footprint expands, maintaining stable processes in new environments, such as additional production lines or new facilities, is essential to uphold product quality and operational efficiency.

Holistic Planning – Leveraging Automation and Digitalization for Rapid Scaling

Emerging battery cell manufacturers must take a holistic approach, integrating advanced planning, automation, and digitalization to overcome these challenges and ensure rapid scaling.

Advanced Planning

Advanced planning forms the foundation for successfully ramping-up and scaling a gigafactory. This involves several critical components:

- Integrated Market Analysis and Forecasting: Accurately predicting market demand and trends is vital. Manufacturers can accurately forecast EV adoption rates and battery cell demand using advanced analytics and predictive modeling. This ensures strategic alignment with market dynamics, reducing the risk of over- or undercapacities.

- Strategic Financial Planning: Securing sufficient funding and financial backing is essential for large-scale projects. Understanding the major cost drivers of a battery gigafactory enables better decision-making and reduces CAPEX and OPEX. Developing robust financial models, engaging with a diverse range of investors, and establishing clear financial goals and milestones ensures the availability of necessary financial resources.

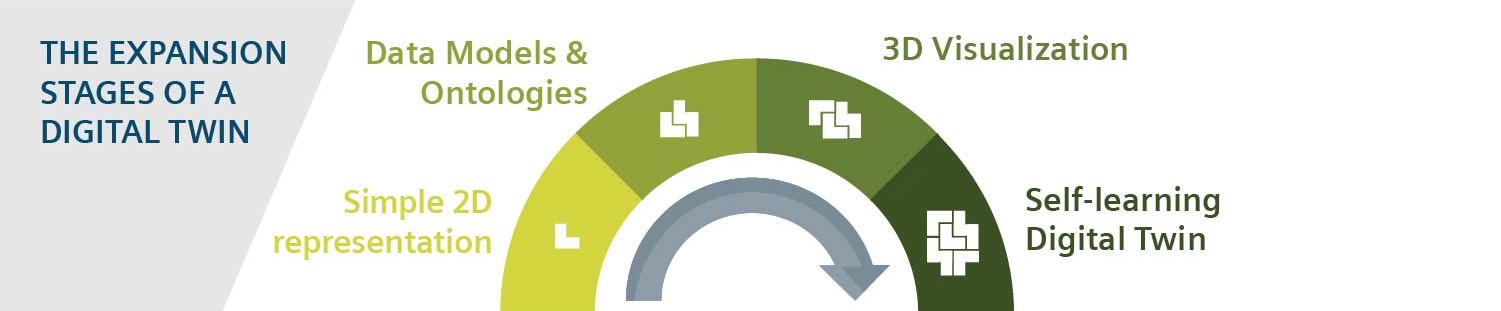

- Digital Twin Technology: Enhancing gigafactory design and planning with digital twin technology allows manufacturers to create virtual models of the gigafactory. This enables detailed simulation and optimization of production processes, facilitating flexible and scalable factory designs. Additionally, virtual equipment commissioning accelerates new product introduction in a "safe" environment.

- Virtual Product Design: Balancing performance and cost through virtual product design is essential. Engineers can analyze thermal management, electrochemical performance, and mechanical stresses under various conditions by simulating physical behavior and rapidly validating designs. This approach identifies potential issues and optimizes designs before building physical prototypes, saving time and resources.

Automation

Automation is an essential component in enhancing production efficiency and scalability within gigafactories. Key aspects include:

- Advanced Manufacturing Systems: Implementing advanced automated production lines, robotics, and AI-driven quality control systems reduces manual labor, minimizes errors, and increases production speed and consistency. Transitioning from predictive to adaptive systems necessitates close collaboration with machine builders to achieve the target operating model.

- Automated Testing and Feedback Loops: Integrating automated testing systems that provide immediate feedback and adjustments to production processes, enhancing overall product quality and reducing waste.

- Energy Management Systems: Integrating automated energy management solutions optimizes energy consumption, reduces costs, and enhances sustainability. Smart grids, AI-based energy forecasting, and automated demand response systems contribute to more efficient energy use within gigafactories.

Digitalization

Digitalization is vital for enhancing operational efficiency and resolving bottlenecks in gigafactories. Key elements include:

- Data-Driven Decision Making: Implementing IoT sensors, real-time analytics, and AI-driven decision support systems at every production stage provides actionable insights for continuous improvement and quick issue resolution. Real-time data collection and analysis help identify inefficiencies, predict maintenance needs, and optimize processes, with AI offering predictive analytics and automated responses.

- Digital Twin of Production: This technology improves operational efficiency by simulating processes and predicting outcomes. The virtual model enables testing and optimization in a digital environment, leveraging real-time data and analytics to foresee issues and suggest improvements. Consequently, it boosts efficiency and reduces downtime.

- End-to-End Digital Integration: Integrating end-to-end digital systems across the supply chain, production, and distribution networks into a single cohesive digital platform enhances coordination, reduces information silos, and improves overall operational transparency.

Leveraging a holistic approach ensures streamlined operations, cost reduction, and a competitive edge in the rapidly evolving battery manufacturing industry. This comprehensive strategy encompasses all aspects necessary to ramp-up and scale a Gigafactory effectively.

Best Practices – Lessons from a European Supercapacitor Leader

A top-tier European supercapacitor cell manufacturer scaled its production capabilities, positioning itself at the industry's forefront through strategic planning, advanced automation, and digitalization. The company predicted EV adoption rates using advanced analytics and market research, aligning production with future needs and avoiding overproduction risks. Diverse financial models attracted investors, ensuring sustainable growth and operational efficiency. Virtual product design balances performance and cost, creating a sustainable supply chain that meets high market standards.

Implementing virtual commissioning and digital twin technology improved production line setup and testing, reducing planning and setup time by 30% and operational costs by 15%. Flexible factory designs enabled rapid market adaptation, ensuring a competitive edge. Additionally, automation, including robotics and AI-driven quality control, lowered scrap rates by 30% and increased production efficiency by 20 p.p. Data-driven predictions have improved logistics, ensuring timely raw material availability and reducing lead times by 25%. Automated training programs and VR simulations effectively prepared the workforce to operate sophisticated machinery. Digitalization has enhanced operational efficiency through IoT sensors, real-time analytics, and AI-driven decision-making, continually improving production processes and doubling cell output.

Meanwhile, end-to-end digital integration enhanced coordination and transparency across the supply chain, using digital twins to optimize operations dynamically. This strategic transformation allowed efficient production scaling, high-quality standards, and cost reduction, securing the manufacturer's position as a European leader in the supercapacitor cell market. Embracing innovation and strategic foresight, the company met market demands and set new industry benchmarks, solidifying its competitive advantage in the rapidly evolving EV landscape.

Seizing the Future – The Imperative Race for Emerging Battery Cell Manufacturers

As demand for electric vehicles surges, emerging battery cell manufacturers are under intense pressure to keep up with rapid growth, high expectations from EV makers, investor demands, and fierce competition from established players. In this volatile and fast-changing environment, the gigafactory stands out as a critical factor in shaping the future of energy and transportation.

To navigate this uncertainty successfully, manufacturers must embrace a holistic strategy integrating advanced planning, automation, and digitalization. Scaling production quickly and efficiently will be crucial as the battery market evolves. How these emerging players address these challenges will determine their success and profoundly impact the global energy transition and the drive toward a sustainable future.

Battery cell manufacturers must take decisive action now. They can maintain a competitive edge in this ever-changing landscape by investing in thorough planning, focusing on automation, and adopting digital technologies. As the future of energy and transportation unfolds, those who can innovate and scale effectively will lead toward a more sustainable and electrified world.

Our contributors

https://www.marketsandmarkets.com/Market-Reports/electric-vehicle-market-209371461.html

https://www.fortunebusinessinsights.com/industry-reports/electric-vehicle-market-101678

https://www.fastmarkets.com/insights/whats-in-store-for-ev-demand-in-2024-and-beyond/

https://ev-volumes.com/news/ev/global-ev-growth-forecast-in-2024-but-challenges-remain/

Author

Digital Core Data Driven Organizations

The Digital Core and Its Role as the Backbone of Data-Driven Organizations

Data is everywhere and whether you are a CEO or business manager you need to know where it is and what to do with it. The amount of data created daily around the globe continues to increase at exponential rates. It is estimated that 163 zettabytes of data will be created worldwide by 2025. However, reporting by IDC indicates that “only 32% of the data available to enterprises is ever used and the remaining 68% goes unleveraged” leading to businesses missing millions in revenue.

If used correctly, data is an asset to any organization. “Ninety percent of enterprise analytics and business professionals say that data and analytics are key to their organization’s digital transformation initiatives. However, there are many companies that are reluctant to pull the trigger because they aren’t sure about the advantages of becoming data driven.”

A data-driven organization captures the power of this ever-growing asset (data) and makes strategic and tactical decisions based on that information, not on gut reactions, historical references, or personal opinions.

Despite the reluctance of some leaders, there is proof that becoming a data-driven organization is beneficial:

- “Data-driven organizations can outperform their competitors by 6% in profitability and 5% in productivity. Data-driven organizations are 162% more likely to surpass revenue goals and 58% more likely to beat their revenue goals than non-data-driven counterparts.”

- Through a data-driven cost modeling approach, an EV start-up business ensured the profitability of its product at scale. This collaborative, data-led engagement with a focus on the supply chain resulted in an overall reduction of over 25% in Bill of Materials (BOM) costs.

- BARC research surveyed a range of business leaders and found that those “using big data saw an 8 percent increase in profit and a 10 percent reduction in cost.”

- The correct data can also shape an organization’s sustainability success. For example, “One Life Sciences company has a state-of-the-art continuous manufacturing facility … Live operations data is fed into a virtual twin, enabling continual optimization through real-time analytics. This initiative has seen an 80% reduction in energy consumption and CO2 emissions, a 91% reduction in the facility’s water footprint, a 94% drop in the use of chemicals and a reduction of 321 tons of waste per year. What’s more, it’s 80 times more productive, making medicines for twice the number of patients in less time.”

The Hybrid Model: An Evolution Requiring the Digital Core

Data holds the power to improve decision making and create new opportunities for growth and innovation throughout the organization. To truly be data driven and leverage the value of enterprise information, organizations need a secure, holistic view of its digital and cloud strategy. This includes how and when to deploy powerful off-the shelf software or when to customize and rapidly apply new use cases built on existing IT infrastructure.

For years the question businesses faced when applying new digital solutions to existing operations was – should we make or buy? Given the availability of open innovation especially through recent releases from AWS and Microsoft, the same question leads to a new answer: We need to do both - make and buy.

The Xcelerator program from Siemens is an example of such a hybrid approach. The robust ecosystem of sellers and developers with integrated hardware and software leveraging a strong solution portfolio and interconnectivity of systems, companies can apply specific operations improvements via SaaS products. A custom-built add-on approach allows them to quickly apply the newest innovation or business requirement delivering significant business impact.

The Digital Core serves as a remarkable illustration of Siemens Xcelerator's vision to enhance collaboration and co-creation. It demonstrates interoperability by seamlessly integrating with both Siemens and third-party systems. Moreover, it is intentionally designed to be flexible, allowing for the creation of tailored solutions according to customer-defined use cases, with the added benefit of expandability and scalability. Lastly, it embraces openness through the use of standardized application programming interfaces (APIs).

The Digital Core operates not as a super platform dominating everything, but as an integral component running in parallel with existing systems. It seamlessly integrates necessary and minimal data to fuel new business logics and processes, leveraging outputs from various systems. Therefore, adding a customized Digital Core to the digitalization mix enables companies to use qualified data and existing corporate knowledge to transform into a powerful decision-making body. It also allows them to own their digital backbone with the option and availability to scale it over time.

Having a Digital Core creates a new level of data ownership that is fully customizable and scalable to meet the company’s needs. This positions the organization to answer additional new business needs by repurposing data from SaaS/PaaS products landscape for advanced analytics and decision making. This will enable enterprises to create new IP or build their own data team, further accelerating digital transformation with the benefit of not relying 100% on third party vendors.

It’s Time to Take the First Step To Transform Your Business

Establishing a Digital Core and becoming a data-driven organization are not overnight processes. It is important for leaders to grow the Digital Core on a case-by-case basis and for critical business reasons. The biggest leap leaders will take is simply to start designing and building the Digital Core framework.

Here are seven points to consider when establishing the Digital Core:

1. Align the company’s data strategy with corporate strategy and involve champions at the highest level of the organization.

2. Secure enterprise-wide buy-in and understanding of the changes involved in becoming data-driven including the impact on the company culture.

3. Demonstrate the potential value of your data by selecting the most valuable use cases where data can drive strategy for success.

4. Create an IT/OT blueprint and detailed roadmap of the expected journey.

5. Design the Digital Core with consideration of the company’s existing digital infrastructure and software products in use.

6. Scale the Digital Core into new areas of the organization and increase its functionality for success, even consider how the data could be used in multiple ways.

7. Consider implementing an expert team who own the organization’s data and Digital Core to create accountability, to continuously incubate new innovations, and to improve data-driven decision making.

AI, Sustainability, and the Digital Core

Sustainability and Artificial Intelligence (AI) provide the perfect business cases to leverage data across the organization because their importance can be quantified quickly due to recent developments and the speed of innovation.

The importance of harnessing enterprise data can be seen in the worldwide effort for better, more accurate sustainability reporting. For example, in Europe, organizations must comply with the Corporate Sustainability Reporting Directive, providing details on sustainability-related impacts, opportunities, and risks. The US and the UN have other reporting requirements that are also dependent on good data sources. Without access to the correct sustainability information organizations may struggle to complete the requirements.

And the next challenge is already on the horizon – optimizing – operations based on data driven decisions. This can only be achieved with qualified, reliable data which includes new business logics and advanced analytics to understand and predict impacts.

Data-driven organizations measure their environmental impact such as CO2 emissions and waste and water consumption across a large infrastructure. Then with the right data quality they optimize operations to reduce their ecological footprint. Finally, they augment their ability to make faster, more effective decisions and support new ways of working with more diverse teams and communities.

Meanwhile, AI is gaining more attention around the globe.

Satya Nadella, CEO of Microsoft, explained that the rate of AI adoption depends upon each specific firm, rather than which industry sector it belongs to. “I think whether it’s in financial services, retail or even healthcare, it’s very exciting to see the broad swathe of industries being reshaped [with AI].”

AI is important because it helps manage large and complex data sets to extract information usable for the company. AI-powered tools like Microsoft Copilot allow users to interact with complex systems using natural language, making it easier to extract valuable information. AI also benefits labor-intensive activities such as cataloging, cleaning, integrating, and organizing the data that goes into the Digital Core.

Securing Leadership Support for Digital Core

The Digital Core opens opportunities for companies, but it also generates debates within the C-Suite with challenges from finance to security, and IT. Let’s debunk some of these pain points:

Security Measures in the Digital Core: In the digital landscape, security is a paramount concern for CXOs. The Digital Core is custom-built on hyper-scaling cloud technology and incorporates robust security measures (i.e., advanced encryption protocols, multi-factor authentication, and continuous monitoring for potential threats). The architecture prioritizes data integrity and confidentiality, meeting industry compliance standards.

Cost-Efficiency Strategies: Cost-effectiveness is a constant challenge for CXOs. The Digital Core optimizes resources through cloud scalability, allowing organizations to pay only for the resources consumed. The absence of a subscription model further empowers clients by providing transparency and predictability in budgeting, eliminating unexpected financial burdens, and allowing for efficient allocation of resources.

Seamless Integration Capabilities: For CIOs a pain point is the complexity of integrating diverse IT and OT systems. The Digital Core is designed with openness and scalability in mind, facilitating seamless integration with various systems and applications. Through well-defined APIs and standardized data formats, it ensures interoperability, allowing organizations to adapt and expand their technology stack without major disruptions. This addresses the concerns of CIOs regarding system compatibility and ease of integration.

Scalability for Future Growth: CFOs often worry about the scalability of digital solutions and impact on long-term budgets. The Digital Core, built on hyper-scaling cloud technology, is inherently scalable. It grows with the organization, accommodating increased data volumes and expanding operational complexities without compromising performance.

Ownership and Control of Data: CXOs are concerned about data ownership and control. The Digital Core addresses this by making the organization the sole proprietor of its data. Unlike subscription-based models where intelligence might be hosted externally, a custom-built core ensures know-how stays with the corporation as is not embedded in an external software which might not be available as necessary and is not part of the digital backbone of its daily operation.

The technical architecture of the Digital Core not only empowers organizations to harness the benefits of digital transformation but also directly addresses the key concerns of CIOs, CXOs and CFOs. By providing a secure, cost-effective, and seamlessly integrable solution, the Digital Core becomes a strategic asset in driving the success of modern enterprises.

Building a Solution with the Digital Core

Once a business reason / use case is defined to create new insights (e.g. sustainability challenges) or innovation infusion (AI), a Digital Core needs to be created which involves key components including:

- Data Structuring: This component not only manages data ingestion and acquisition but ensures efficient storage, retrieval, and transformation. It plays a pivotal role in structuring data to align with organizational needs and standards, enhancing its overall utility.

- Front-end single pane of glass: Serving as the main user interface for operational data, the web application is designed with a user-centric approach, providing an intuitive experience. It fosters collaboration by centralizing data analysis, featuring dashboards for multiple KPIs, other metrics, and an alarms and notifications system.

- Analytics: The analytics application offers flexibility with customizable reports, providing insights into various parameters. Its adaptability and scalability make it a robust tool for evolving data needs and technologies. Additionally, it facilitates diagnostics, high-level management, and control capabilities across connected subsystems.

- Integration Layer: Operating as more than just a storage area, this component serves as a dynamic communication backbone, facilitating seamless data flow within and between data centers. Its versatility in supporting various data formats and protocols enhances its role in integrating data from defined subsystems.

- Process Automation and Event Processing: Working alongside the Integration Layer, this component excels in real-time capabilities, managing automated processes and pipelines for data processing. It ensures data quality, consistency, and reliability, contributing to the overall efficiency of the Digital Core.

- Work Order Management: Derived from insights provided by the web application and reports, the work order management component streamlines operations by initiating actions. It plays a crucial role in fostering a proactive approach, addressing issues promptly, and optimizing workflows based on analytics and data-driven decision-making.

Each of these components works together allowing the Digital Core to enhance strategy implementation through data driven insights generated from combining external market data with the company’s own performance, lower operations and maintenance costs, reduce failure rates, and achieve the highest return on investment. Overall situational awareness is provided for connected infrastructure, serving as a single point of reference for all involved in joint decision making.

For example, a Port wants to create situational awareness of its operating entities, with the goal of delivering services to all stakeholders to improve the operational performance and efficiency. This will at the same time increase supply chain transparency or full emissions footprint through the implementation of the different views on an integrated control center. By creating a Digital Core and a Common Operational Picture (COP), the Port Operator would meet the need for awareness across its operation of a single port or multiple locations it is managing across the globe. The COP will replicate information from related sub-systems, and be shared between the command, control and coordinating groups serving as a single point of reference for all involved parties for joint decision making. The Digital Core creates additional insights by further processing the data from the subsystems to create prediction models for operations.

Pulling It All Together

Leaders may arrive at this point in this post and feel overwhelmed by the importance of the Digital Core and how complex the transformation is for their organizations. There are still so many business leaders who do not see how data and powerful innovations will radically change their businesses. Successful companies will run a hybrid strategy build (Digital Core) and buy (SaaS), leveraging great software products for specific operations. Optimization and an owned Digital Core create enterprise intelligence and control of their digital transformation. To achieve this, leaders will need a guide and engaging the right partner with extensive IT/OT and digital transformation experience is critical for success.

And remember – the goal is not to connect everything with everything. The Digital Core runs on minimal data with meaningful use cases embedded and can be created based on individual issues or use cases that a specific company faces. It underpins total enterprise reinvention by providing agility, flexibility, easy interoperability, and resilience.

Our contributor

Our industry leader

A Data-Driven Organization Requires Everyone’s Hands on the Wheel - DATAVERSITY

A New Survey Finds Increasing Business Impact Of Data And AI Executives (forbes.com)

Data-driven sustainability: Using data to drive change (genpact.com)

Digitalizing Buildings: It’s Time To Catch Up (forbes.com)

EcoDigital Advantage with Sustainability and Digital Fusion | BCG

Getting the most from your data-driven transformation: 10 key principles | MIT Technology Review

How AI Is Improving Data Management - MIT Sloan Management Review

How Data Will Drive Sustainability Forward (forbes.com)

https://financesonline.com/relevant-analytics-statistics/

https://towardsdatascience.com/why-organizations-need-to-be-data-driven-98ade3ca53a

https://www.consilium.europa.eu/en/policies/green-deal/

New IBM Study Explores the Changing Role of Leadership as Businesses in Europe Embrace Generative AI

Total Enterprise Reinvention | Accenture

WEF_Bridging_Digital_and_Environmental_Goals_2021.pdf (weforum.org)

What is Orchestration? (databricks.com)

What Will It Actually Take To Lead A Modern Data-First Organization? (forbes.com)

Author

Data and IoT for Automated Sustainability Reporting

Data and IoT for Automated Sustainability Reporting

Using Data and IoT Frameworks to Boost the Sustainability Reporting Process

Sustainability reporting has come a long way since the publication of the first environmental reports in 1989. But so has that amount of data that companies generate.

In a company's data lies a spectrum of information, spanning from product development details to environmental measurements. However, this diversity in data is often spread across multiple departments, complicating the task of gaining a comprehensive understanding of the whole picture. Breaking down silos or accessing data in divergent systems is a challenge. All of this leads to companies not knowing exactly what data they have access to daily.

As a Harvard Business Review article notes: “Increasingly, companies must come to recognize and appreciate that data is a business asset that flows through an organization. Data cuts across traditional organizational boundaries, often without clear ownership.” With the increased amount of data and the lack of visibility across the business, for most companies, corporate sustainability reporting and monitoring is a tedious and time-consuming task. It often involves manual data collection, data processing, and interpretation. Data constitutes the foundation for various use cases in sustainability reporting (e.g., value chain mapping).

Sustainability reporting and monitoring is becoming more important to customers, politicians, employees, and investors. In fact, “Businesses are not gauged through their financial performance alone. Instead, stakeholders weigh in more on the sustainability aspect of the business than just the profitability.”

Several new reporting rules require data and transparency from companies no matter where they are in the world. For example, in Europe, organizations must comply with the Corporate Sustainability Reporting Directive, a part of the Green Deal reforms, requiring details on sustainability-related impacts, opportunities, and risks. Germany has its Supply Chain Act. And in the U.S. companies are responsible for reporting via the United States Security and Exchange Commission’s (SEC) new climate risk disclosure rule. The UN has additional reporting obligations that also rely on high-quality data sources.

Research by ESG Book found that “1,255 ESG regulations have been introduced worldwide since 2011, compared to 493 regulations published between 2001 and 2010. Since the turn of the millennium to the present day, there has been a 647% increase in ESG regulations.” Without access to the correct sustainability information organizations may struggle to complete requirements.

“Put simply, noncompliance is not an option and could have significant consequences.” Errors or avoiding any of the regulations can result in fines and damage the overall reputation of the company. According to Harvard University Law School’s Forum on Corporate Governance’s report, The State of U.S. Sustainability Reporting, “There has never been a more important time to ensure that company sustainability disclosure is robust, clear and credible—while also keeping pace with the rapidly evolving demands of stakeholders.”

Manual Sustainability Reporting Must Go

Sustainability reporting creates internal accountability as well as transparency and accountability with external stakeholders. Reporting on sustainability can be complex. It is often made more difficult because leaders do not know specifically what information to report. They are also unaware of the data they have within their grasps leading to one of the largest challenges to achieving sustainability reporting requirements – the way companies gather data for those reports.

In these situations, the employees do the best they can to interpret the data manually which often leads to errors. A recent Qlik survey showed, “… just 24% of the global workforce claimed to be fully confident in their ability to read, work with, analyze, and argue with data.” In addition, “85% of organizations believe they are ahead of their peers concerning sustainability reporting, but almost half (47%) still use spreadsheets to aggregate their data.”

There is hope for improving the process for obtaining required information for sustainability reports. In fact, leading organizations have turned to technology to automate the harvesting and interpretation of data.

IOT Framework Delivers Automation and Connectivity

Achieving the technical automation necessary to assist in data gathering for sustainability reporting requires both a clear business strategy and an appropriate structure to unite IT/OT and other various data sources within the organization.

Let’s look at the strategic component. There are four questions that the executive team needs to ask:

- What data are we already collecting?

- What data is required for reporting regulations?

- What do we want to collect in the future?

- Who is responsible for capturing and harmonizing the data?

Once there is a clear and documented approach capturing the data required for automated collection and report generation, then the company can move to building the appropriate IoT framework to make this solution a reality.

“An IoT framework is a set of protocols, tools, and standards that provide a specific structure for developing and deploying IoT applications and services.” It enables collection, standardization, and processing of data. It also connects with IT/ OT where data from various sources within the company (e.g., in ERP systems or on operational/shopfloor level) are assimilated, hosted centrally, and interacted with through a dashboard. The entire process is done in real-time, is cost efficient, reliable, and easy to use. Ultimately, the IoT Framework generates a holistic overview of the company and its progress on ESG initiatives.

A critical part of the IoT framework is the interplay of the semantic layer and processed data because it is the foundation for future processing to aid in certification, reporting and visualization. Since the data is from various places within the organization and may not follow the same format or criteria, “it is necessary to implement a method of sophisticated data integration … it is challenging to efficiently fuse a large amount of probably noisy data and then infer an accurate result.”

“Incorporating data fusion, the process of merging multi-source data to increase integrity, allows companies to effectively deal with noisy data of dynamic environment, and helps the decision-making process based on the available information.” This means the heterogeneous data of an organization is conveyed, stored, and accessed in the same way. “The data structure is expressed through the links within the data itself, it is not constrained to a structure imposed by the database and does not become obsolete with the evolution of the data. When changes in the data structure occur, they are reflected in the database through changes in the links within the data.”

Benefits of the IoT Framework

Automatically generated sustainability reports provide several advantages compared with manual processing, including: a reduction in errors, allowing employees to focus on more value-added work, and faster, more accurate production.

In addition to ensuring accurate data is available and referenced in automated sustainability reports, the IoT framework delivers even more benefits to the organization. For example:

- It allows for improved data quality and interpretation because it can be queried easily, and calculations are based on real data and not average or estimates.

- The interactive dashboard used in many IoT framework solutions is automatically updated allowing the sustainability manager (and others) to manage process on goals.

- IoT frameworks offer advanced visualization and modeling. The information is shareable in several views and dimensions (technical, commercial, geographic).

It’s A Must Do: Sustainability Reporting and Technology

Spreadsheets and manual data entry aren’t made for the era of Big Data and IoT. Changes are necessary across industries and around the globe to move to more automation such as IoT frameworks, especially for gathering data to demonstrate sustainability growth and achievements for companies.

Leaders must accept technology’s role because sustainability reporting is a necessity. In fact, “Regulators and investors hold sustainability reporting to a higher standard: Companies making sustainability claims without defensible data [supporting information generated through a data-driven approach] put themselves at risk of greenwashing lawsuits and other liabilities.”

Embracing technology and implementing robust reporting systems are imperative for companies to navigate the evolving landscape of sustainability reporting, mitigate risks, and position themselves as leaders in sustainability, all while ensuring transparency, credibility, and organizational alignment.

Our contributors

13 proven benefits of sustainability reporting - ASKEL (askelsustainabilitysolutions.com)

7 Benefits of Sustainability Reporting - Why It Matters to Report (brightest.io)

Best Practices for Establishing ESG Disclosure Controls and Oversight (harvard.edu)

Digitalization and ESG Reporting:Guide for Companies | ConveneESG (azeusconvene.com)

Digitalization for Sustainability | UNEP - UN Environment Programme

ESG reporting: The essential guide for 2023/2024 (sustainablefuturenews.com)

How Industrial IoT for Sustainability Improves Your Business - Velvetech

How to keep your ESG data from managing you - Thomson Reuters Institute

Keeping Up With The Sustainability Evolution Through Technology (forbes.com)

Six steps to solving the sustainability data challenge - UKI Think Blog (ibm.com)

Sustainability Reporting Explained: Its Importance & Benefits | GEP Blog

Ultimate Guide to Sustainability Reporting - STACS Network

us-risk-sustainability-disclosure.pdf (deloitte.com)

What can AI tell us about sustainability reporting? - SustainLab

What is IoT? - Internet of Things Explained - AWS (amazon.com)

What is Sustainability Reporting? - ESG | The Report (esgthereport.com)

Author

The Rise in Cognitive Cities, Buildings and Infrastructure as the Next Generation of Urban Management

The Rise in Cognitive Cities, Buildings and Infrastructure as the Next Generation of Urban Management

Urbanization is on the rise. More than half of the world’s population now live in urban areas and this is expected to increase to circa 70% by 2050, according to the United Nations. Around the globe, and particularly in the Middle East, there are many plans underway to develop entirely new urban living areas, to accommodate the population rise and expatriate influx. Both Abu Dhabi and Dubai were recently ranked as the smartest cities in the MENA region. With many new infrastructure plans underway, this ranking is expected to climb even higher globally.

These trends set a pressing need to build and expand services, infrastructure, city management, and controls within these increasingly populated areas. With these numbers expected only to grow, strategic planning is of utmost importance to ensure long-term efficiency, safety, and quality of life. As the technological landscape continues to develop at a rapid pace, and digitization now touches nearly every industry, a key component of current and future planning will be the integration of smart and cognitive solutions.

Bringing Smart Cities to Life

Before continuing, it is useful to set some parameters around what we mean when we say ‘smart’. The word itself is central to so much innovation, and as a prefix, it has migrated away from being attributed to personal devices (such as a smart watch or smart phone), to increasingly becoming a feature of many target systems and services that will be provided by governments and private companies, forming the interface between users, customers and service providers with the end goal being to create more efficient and optimized services. A ‘smart’ system will be able to operate in its own silo, typically without the need for human intervention. It will be able to track, recognize and produce data or responses according to its purpose.

But where are we today? Across the globe, we have been edging towards a more integrated digitized experience for some time now. With new smart features being introduced that form the initial buildings blocks of fully integrated smart cities in the future. The Middle East has already long been a proponent of innovation and leveraging the best of disruptive technology. In particular, the UAE and Saudi Arabia are setting a new benchmark when it comes to smart technology for customers and residents. Smart systems are becoming more common across many government and private buildings and processes and have been for several years now. They provide responsive interfaces for users and consumers and relieve much of the manual efforts, as well as costs to services, and provide significant reductions on environmental impacts. Dubai has over 100 Smart initiatives and over 1,000 smart services - many as a result of collaboration and cooperation between government and private companies. This number is expected to grow significantly, in line with the number of exciting new infrastructure products as part of the agenda to become ‘the happiest city on earth’. This vision is underpinned by the objective of leveraging technological advancements to optimize resources, integrate services seamlessly, and protect people and their information.

Siemens Advanta recently worked with Dubai to complete an Internet of Things (IoT) strategy for the city to help identify, prioritize and define smart initiatives, which included an assessment of central computing platform options to create an integrated citywide command center. Implementation of these initiatives is expected to lead to substantial benefits, including operational cost savings (up to 30%), improvement in overall resident and customer satisfaction (up to 20%), reduction in emergency response times (up to 80%), and reduction in non-revenue water use (up to 35%).

This is an excellent case study for demonstrating that buildings and environments that adapt to human needs, create safer and more harmonized living and contribute to a more sustainable future. Overall, folding smarter and sensory technologies into urban planning, and architectural and interior design will not only increase competitiveness but ensure that present and future generations’ economic, social, and environmental needs are also met.

The Future of Cognitive Cities

Smart security systems, smart access, and smart metering (to name a few) are now becoming part of common jargon. More recently, and in line with the accelerated growth of technology, the term ‘cognitive’ has also entered the lexicon.

What’s the difference between smart and cognitive systems? While a smart system is used to measure, track, communicate, and collaborate with its users, a cognitive system independently intuits and anticipates.

To put it another, simpler way: imagine a meeting that is held in a conference room at the same time every week. The heating system for this room is accessible and controllable from an individual mobile device. Given the number of attendees within the meeting room the temperature of the room can increase, so the users are able to adjust, using their devices. That is a smart system. But now imagine that that same system would recognize both the pattern of the meeting cadence and the increase in temperature and then adjust itself at the same time the following week to accommodate the extra body heat. That is a cognitive system.

Both systems are fundamentally intelligent but as this example shows, while a smart system is able to be digitally controlled, a cognitive system goes one step further and is able to adjust and self-regulate according to user and customer needs. Through prediction and enablement, cognitive systems offer the most sophisticated, human-centric solutions that exist today.

The concept of cognitive is still considered emerging, but it is a trend that we can expect to see growing in the very near future and ultimately, replacing its ‘smart’ predecessor. With the use of self-learning artificial intelligence (AI), a cognitive infrastructure will be able to provide fully integrated solutions that move away from siloed systems, and communicate and learn across a network of enabled services. It is the ultimate vision for a fluid end-to-end process that benefits both the user/customer base and the provider through seamless experiences, while enabling long-term cost savings and significant reductions in environmental impacts for the provider. Simultaneously, its sophistication will only continue to grow with machine learning technology at its core.

But getting it right is key: from the very first point of data, a cognitive system needs to be able to accurately register and understand the user requirements. We have seen minor challenges with this in the recent past, with many of the machine learning technologies that make up cognitive solutions. Given that many of them are still at a comparatively nascent stage, the rate of pace at which they are developing and improving is extremely fast.

Smart and cognitive infrastructure is not just about increasing the end user’s human comfort level and ease of effort. From an economical point of view, they can deliver long-term cost savings by reducing the wastage of services and energy. There is a wider imperative and obligation to ensure that we are investing in longer-term sustainable solutions that will help reverse the negative impact on the environment. As the topic of ESG (Environmental, Social and Governance) rises on the agenda for both government and private companies alike, both are looking to technologies to enable their core objectives. The valuable data collected by these systems can enable city and building management to make informed and strategic adjustments. This covers all three layers of a city and building’s infrastructure:

- The sub-layer: includes water, gas and electricity delivery and waste disposal

- The surface level: engages directly with users, residents and customers, such as transportation, retail, in-person services and recreational activities

- The vertical layer: includes energy consumption

Applying a digital layer across all three of these provides a more detailed insight into gaps and required adjustments than has ever been accessible before.

Paving the Way for Cognitive Transformation

Cognitive systems will provide a competitive advantage across multiple industries, including healthcare, manufacturing, mobility, and buildings. Through customer and user-centric data gathering, these systems can continuously update and amend their operating structures based on customer and user preferences and interactions. Businesses will benefit from ongoing optimizations to their human services, environmental impact, safety & security, utilities, and operational intelligence. Stay ahead of the curve with the limitless potential of cognitive systems.

There is no doubt that technology adds to the desirability and attractiveness of residential properties, communities and services, as well as tourist experiences. From a user and customer perspective, smart and cognitive systems can improve quality, ease of use and safety and security, among many other benefits. Meanwhile, cost reduction, ESG considerations, improved data management, and enhanced governance all stand as pivotal advantages for service providers, thereby futureproofing their business and ensuring continued growth through investments in smart technology.

In the imminent future, the most prosperous communities will have technology at their core, equipped to facilitate growth and development. All businesses, both public and private, should start to consider how their ways of operating will tie in with a larger, more cognitive-based infrastructure that will underpin future ways of living.

Free whitepaper

Each city has its unique requirements to tackle during the transformation that starts with city theory and then becomes smart tech reality! We guide you through the process, with a uniquely comprehensive roadmap designed to successfully implement your smart city, putting technology at the core of it all.

Our contributors

Author

Navigating the Future of Fleet Management

Navigating the Future of Fleet Management

The movement of products from point A to point B is a crucial part of commerce no matter where you are in the world. Commercial vehicles (CV) or trucks that are part of fleets comprised of one to several thousand vehicles transport these products. Post- COVID, the global market for freight trucking continues to grow with a projected expansion to US $2.9 trillion by 2027.

According to our recent research report focused on the European trucking and fleet management industries, out of the 36 million CVs on European roads, 6.4 million are trucks with >3.5 tons. France, UK, and Italy have the biggest fleets in total; while Poland, Germany and Italy have the largest fleets of medium and heavy commercial vehicles. In addition, we found 3.9 million trucks operating in the Road Freight Transport sector in the EU and more than 500,000 Enterprises registered with the same government organization. (1)

That’s an impressive number of trucks and drivers on the roads.

The businesses that own these CVs must have a view of where the trucks are at any given time, which usually falls upon the Fleet Manager to oversee.

In recent years, Fleet Managers turned to digital solutions for efficiency. Fleet management systems (FMS) or professional software that allows the tracking of operations, driver management, and incident management as it relates to the fleet are vital to successful oversight of a company’s logistics, trucks, and profits.

Unfortunately, while FMS are often seen as the number one profitability lever for Fleet Managers to improve operational efficiency of their truck fleets, there is no single, end-to-end, comprehensive solution available on the market today.

According to an article in Forbes Advisor, the complete end-to-end FMS solution would have “core features that allow you to manage your drivers, vehicles, operations and… integrates with other business software tools like inventory management and CRMs. The vehicle management portion of the system should allow you to track your drivers and vehicles, such as through a GPS tracking system. It should also make operations management run smoother by helping you manage fuel and labor costs and provide proper trip planning for your drivers and customers.”

Today, Fleet Managers must review multiple platforms to obtain an accurate picture of their organization’s operations, safety, and other critical data. Despite having a large and significant role, Fleet Managers find themselves stuck with an inefficient process.

Our research confirms that the FMS market in Europe is very fragmented. For example, the top 10 FMS providers collectively hold a market share of approximately 30%, with an estimated 13.2 million active units in Europe. These providers include Original Equipment Manufacturers (OEMs), Original Equipment Suppliers (OES), and Software Solution Providers. Today, each works in their own area. For example:

- OEMs build their own FMS solutions with some collaboration initiatives.

- OESs start building ecosystems by acquiring software solutions providers (ex. Bridgestone purchased Webfleet, formerly known as TomTom Telematics, for €910 million).

- Telecom providers such as Verizon and Deutsche Telekom build the backbone of FMS by offering IoT modules, terminals and network services while also offering their own FMS.

While the breadth of services offered by these three groups seems thorough, we still must ask: ‘Why is there no single solution to this clearly obvious industry challenge?’

The answer is that no company has been able to connect all required information into one system. This is a tremendous opportunity for leaders looking to transform the FMS industry.

Waves of Opportunity Flooding the Global FMS Industry

Against the backdrop of an inefficient FMS solution, the global FMS industry is experiencing market consolidations through M&A, a push to innovate, and an increased number of partnerships formed.

Recent significant partnerships include:

- Renault’s June 2022 partnership with telematics supplier Geotab to integrate its models into the MyGeotab fleet management platform. The collaboration will enable fleet managers' decision-making through enriched data and access to connected solutions for fleets of any size. Any Renault model built in 2010 or later is compatible with the integration and can receive a factory-fitter or retrofitted telematics solution for vehicles in the field. The new telematics solution is available for fleets in 21 European countries, including France, Germany, Spain, Italy, the UK, and Nordic countries.

- Geotab Inc., a global leader in IoT and connected transportation, entered into a partnership with Sygic in December 2021 to provide customers with offline GPS navigation and route planning for trucks and light commercial vehicles.

- Webfleet, Bridgestone’s FMS, enables the integration of its telematics solutions in all MAN trucks with the existing OEM hardware RIO Box from MAN (May, 2023)

Additional partnerships and M&A activities will have a significant impact on the landscape of the market – from defining the market leaders to potentially creating the FMS that Fleet Managers need to do their jobs.

Three Actions for European Fleet Management Success

There is always room for industries to improve. We offer recommendations for change in the European market specifically it’s time for European FMS providers and data owners to prioritize a new organizational mindset. This mindset promotes integration and embraces innovation to stay competitive in the highly fragmented, and dynamic market. Let’s look at each of these a bit closer.

Organization Mindset

- Apply venture approach: Establish independent digital builders with adequate funding by applying venture capital principles.

- Initiate mindset change: Establish fail-fast culture, iterative design-thinking, and persona-focused product development.

- Push comprehensive thinking: Focus both on “pure” digital revenues and their “pull-through” role as drivers of hardware sales.

Integration

- Build ecosystem partnerships: Partner or acquire industry players to accelerate product development and third-party marketplaces. For example, the recently announced partnership between Webfleet by Bridgestone and RIO by TRATON.

- Guarantee FMS integration: Fully integrate FMS in existing IT-landscape of fleet manager including CRM and carrier Transportation Management support.

- Become hardware agnostic: Decouple hardware from service portals to guarantee low switching costs and multi-brand fleet support.

Innovation

- Use big data: Differentiate through innovation by being at the forefront of big data analytics and machine learning.

- Offer data brokerage services: Leverage power over data interfaces by offering commercialized data sharing to industry players.

With these elements in place, we can envision a future where trucks are fully connected, and fleet management is optimized and highly automated with state-of-the-art digital solutions.

Unlocking the Potential in the Truck Fleet Industry Starts Today

As the global trucking industry is expected to grow, the FMS industry anticipates expanding to reach US$55 billion by 2030. (2) Combined with the three megatrends of market consolidation, technology innovation, and developing industry ecosystems, it is time to capture the full potential of this market while not losing competitiveness. There are many opportunities for those companies in Europe (and beyond) that rethink strategies and leverage innovative digital solutions.

Consider these next steps to enable fleet management success:

- Building or participating in one-stop-shop fleet management ecosystems addressing all the needs of fleet managers in their daily operations

- Using data sharing principles in ecosystems to enable big data analytics and machine learning (predictive maintenance)

- Growing connected services business by keeping up with the competition and profit from strong FMS market growth in the next decade

- Being part of a more sustainable future by driving operational excellence in truck fleets

- Driving hardware/truck sales with state-of-the-art FMS and multi-brand fleet compatibility features

Leveraging digital solutions, creating ecosystems, and simplifying processes will transform this essential market.

(1) Fleet Management Truck Europe – Next Level (Siemens Advanta Consulting)

(2) Precedence Research, August 2022

Our contributors

Author

Networks and Data Ecosystems Essential for the MedTech Industry’s Circular Future

Networks and Data Ecosystems Essential for the Medtech Industry's Circular Future

The concept of circular economy is not limited to only manufacturing or waste management sectors – it is crucial for every industry, especially MedTech and healthcare. Owing to increasing environmental damage and pollution rates caused by large corporations, other equally responsible sectors have been overlooked in the public domain.

MedTech is any technology used to save the lives of people suffering from a wide range of conditions. It can range from syringes and latex gloves to heart values and pacemakers or replacement joints for knees and hips to total body scanning machines.

The future of MedTech lies in the power of networks and data ecosystems, enabling the industry to build a circular and resilient healthcare ecosystem. Data ecosystems include various actors, like services, and software applications that use data to share and utilize it economically or socially. In many circular economy scenarios, this involves the network or the networking of companies. “By making these changes, transformation of the medical device industry to a more circular economy would advance the goal of providing increasingly complex care in a low-emissions future.”

What does a circular economy look like for MedTech?

In the following article we will provide experience-based insights on why MedTech companies must embrace networks and data ecosystems to navigate this complex landscape. Furthermore, we will show how companies managed to harness the power of connectivity and data-driven insights to meet the demands of a circular economy and beyond - ultimately thriving in a sustainable future.

Not If but when: Five reasons why the circular economy is crucial for MedTech

Even with these barriers, our experience shows that there are several significant reasons why MedTech companies need to invest in circularity, including:

- Regulatory compliance: By closing raw material loops and thereby reducing the product carbon footprint, the circular economy is a crucial element in a wide range of relevant frameworks and regulations (e.g., UN Sustainable Development Goals, Paris Agreement, Green Deal, etc.) and therefore an imperative to avoid fines and penalties.

- Resource Efficiency and Cost Savings: In times of rising material prices, using recycled or reclaimed materials leads to cost savings in raw material procurement, production, and waste management thereby improving the company's profitability and operational efficiency.

- Resilience and Supply Chain Stability: By reducing the dependence on scarce resources and minimizing vulnerability to price fluctuations or supply chain disruptions, circularity contributes to mitigating the risks associated with decoupling, climate change, resource depletion, and economic instability.

- Access to Sustainable Financing and Investors: Companies that embrace circularity are more likely to attract sustainable financing options and gain the interest of investors seeking companies with strong ESG performance, ultimately providing access to capital for growth and expansion.

- Development of new business models: Circularity drives companies to innovate in product design, business models, and operational processes leading to the generation of new revenue streams and services that provide ongoing revenue instead of relying solely on one-time sales.

Catena-X: The crossroads of data, infrastructure, and service

Let’s explore how circularity is improving industries like Automotive and ways in which we can apply these insights to the MedTech industry.

Increasingly stricter environmental regulations regarding electric mobility, rising prices of raw materials, and supply chain shortages provided an impetus/incentive for the German Association of the Automotive Industry (VDA) to start the development of Catena-X in 2020. This became one of the first and biggest circularity-focused digital ecosystems that connects companies throughout the automotive value chain.