Strategy and Digital Transformation

Strategy & Digital Transformation

Siemens Advanta approaches digital transformation in a customer-centric way to accompany our clients on their digital journey to sustainable success.

Comprehensive digital transformation solutions for sustainable success

Digitalization has revolutionized how businesses operate, resulting in dynamic markets, evolving technologies, and shifting trends. As companies navigate increasing complexity and uncertainty, meeting changing customer expectations is crucial for success. At Siemens Advanta, we enable businesses to unlock their full potential by embracing digital transformation while always keeping the customer in focus. Leveraging our vast expertise, we deliver tangible results for our clients in record time, covering every aspect of their digital transformation journey. Together, we pave the way for win-win solutions and superior customer experiences.

Explore our tailored portfolio to support your business needs

Latest Strategy & Digital Transformation insights

Our industry leaders

Driving digital transformation and open innovation with a strong ecosystem

Tune in to uncover what the world of open innovation ecosystem holds for the future.

How can cross-collaboration and open ideation help deal with industrial uncertainties? Get your answers from Aymeric Sarrazin and Peter Körte.

Find us also on your favorite Podcast APP:

Apple Podcast, Google Podcast, Siemens.fm,

Stitcher, Spotify (log in to listen on desktop)

Remember Your Digital Twins When You Enter the Metaverse

Remember Your Digital Twins When You Enter the Metaverse

The Metaverse is the next chapter of digitalization and offers enormous possibilities.

But what is the Metaverse? As of today, there is no universal definition.

Siemens Technology provides this perspective: "The Industrial Metaverse (IM) is a space to experience Digital Twins, enabling faster, more efficient and less resource intensive problem solving. Real-time data and predictive information made available to people collaborating in a virtual, immersive environment, facilitates smart and even autonomous decision-making across the entire product lifecycle."

A second view presented by Gartner is that the Metaverse is “A collective virtual shared space, created by the convergence of virtually enhanced physical and digital reality. A Metaverse is persistent, providing enhanced immersive experiences.”

Meanwhile, the author of an IOT World article stated: "The Industrial Metaverse is an ecosystem for industrial innovation, integrating new technologies with the real economy. In this way, the digital world is free of physical space constraints, forming a highly dynamic digital world with abundant resources. The Industrial Internet infrastructure is the core of the Industrial Metaverse, but not its only part. Despite its similarities to the Internet, it’s crucial to understand how this new ecosystem can transform the industrial world.”

Adding to the complexity about defining the Metaverse, ABI Research notes three Metaverse “worlds”:

- Consumer Metaverse: Providing digital services and media (gaming, social media)

- Enterprise Metaverse: Using benefits of increased collaboration and immersion in the context of enterprise application (education)

- Industrial Metaverse (IM): Providing benefits to industries core processes, specifically tapping improvement potentials with Digital Twins and simulations (manufacturing).

Today, many associate the Metaverse with the world of games, online retail, and social media. But one could argue that the most significant and biggest potential of the Metaverse lies with industries that make up the backbones of our economies – manufacturing, buildings, grid and infrastructure operators, or the transportation sector.

In fact, according to Michael Inouye, principal analyst at ABI Research, the Industrial Metaverse will grow faster than both the Consumer and Enterprise Metaverses.

Why will the IM be larger than the Consumer or Enterprise Metaverse?

- The IM is ahead on 3D simulations and Digital Twins.

- The IM is ahead on standards like Nvidia’s Omniverse platform.

- The consumer space is fragmented, with multiple companies claiming to have established “Metaverses,” most of which are not interconnected or interoperable. Digital assets are typically locked to a particular ecosystem, servicer or game.

- The IM are also better grounded in ROI, meaning more trials and initial deployments have a higher potential to succeed or lead to more adoption compared to consumer efforts.

Whether you see the Metaverse as a consumer, enterprise, or industrial game-changer, the truth is that the market is growing. According to Statista, “the Metaverse market will be worth $678.8 billion by 2030.”

Digital Twins: The origin of the Industrial Metaverse

The Industrial Metaverse is the next evolution of Digital Twins. Digital Twins are representations of real-world processes and assets in the digital world. The IM differentiates itself from a pure Digital Twin by fulfilling three essential key characteristics (2):

- Immersion: Being “pulled into” a persistent environment by (photorealistic) 3D visualization on screen and/or virtual/augmented reality (XR) devices

- Interaction: Receiving instant feedback from real-world assets and their Digital Twins, as well as between different types of Digital Twins and simulations

- Collaboration: Working simultaneously on the “single source of truth” with multiple contributors, disciplines, and stakeholders.

Once the Digital Twin is established, there are several other technologies that need to be explored and integrated into a company’s digital toolbox and leveraged for IM. These tools and technologies driving the IM include:

- IIOT: Sensors, controllers, and other devices that collect data and allow for remote monitoring and control of industrial processes and assets, as well as high-speed, low-latency networks will be crucial for seamless communication between the virtual and physical systems.

- AI: AI technologies, such as machine learning and natural language processing, can automate and optimize industrial processes and decision-making.

- Augmented and virtual reality: AR and VR tools provide an immersive experience of industrial processes, allowing users to interact with and visualize data in 3D.

- Cloud computing/Edge Computing: The challenge is to find the optimal mix of cloud and edge computing. Cloud computing provides a way to store, process, and analyze large amounts of data, making it easier to manage and access information from different locations. While edge computing supports the IM by enabling much leaner, lighter headgear by offloading a large part of the computer from the device to an edge infrastructure—while also providing superior speed and low latency capabilities. Without edge computing, there will simply be no Metaverse.

- Cybersecurity/Blockchain: Cybersecurity tools secure and protect the IM. Blockchain technology secures and manages data in the IM ensuring that it is tamper-proof and easily accessible to authorized parties.

- 3D modelling/Scanning: Realistic, eventually photorealistic replicas of the real-world support management, operational leaders, and project teams in decision making as they can intuitively feel the change in an environment before it happens in real life. Improvements in scanning technology are needed to quickly generate a realistic 3D model of an environment on the move. This is important to achieve the “Immersive” element of IM.

Five steps to embracing your Industrial Metaverse

While the IM may not be a reality just yet, waiting for it to arrive before starting to embrace it could be a costly mistake for organizations. The evolution of the Digital Twin has already begun, and the next logical step is to build an immersive and collaborative digital world that interacts with the physical world through the IM. Solution architecture is a crucial element of this transformation and data management is the backbone of it all.

Here is a five-step roadmap to embrace the IM:

- Assess current digital capabilities: Evaluate data infrastructure, analytics capabilities, and scalability of digital solutions to identify gaps.

- Develop a strategy for the IM: Identify the use cases that the IM will enable, defining the scope of the initiative, and setting goals and objectives – most importantly understand which IM use cases are relevant to the business and bring a value add – no digitalization for digitalization's sake.

- Upskill the workforce: Generate the necessary expertise to operate in the IM including investing in training programs to develop skills in advanced analytics, AI, and Digital Twin technologies. Ensure that you have the right talent to drive the initiative forward.

- Build partnerships with key technology vendors: Partnerships with key technology vendors and service providers ensure access to the latest tools and expertise required to operate in the IM.

- Invest in technology and infrastructure: Upgrading data infrastructure, adopting new technologies such as 5G and edge computing, and investing in advanced analytics and AI capabilities are essential.

Companies benefitting from the Industrial Metaverse

The industrial metaverse will be an interface between the real and digital worlds and will transform how we work, live, and interact. Let’s look at three early adopters of the IM and what could be on the horizon as they continue the digitalization journey.

Coca-Cola HBC, a partner of the beverage giant, used the IM to enhance the sustainability and resilience of its supply chain. By working with Microsoft, Coca-Cola HBC created an immersive digital replica of its bottling facility in Edelstal, Austria, ultimately minimizing waste and increasing sustainability while boosting operational efficiency. To reduce the carbon footprint associated with transportation, Coca-Cola HBC implemented automated yard management and vision picking which improved resources and availability checks, as well as guiding trucks into loading docks, and minimizing errors. Ultimately, Coca-Cola HBC aims to achieve zero carbon emissions by 2040.

In this example of supply chains enhanced by the IM, Coca-Cola HBC achieved greater operational efficiency, sustainability, and profitability while meeting the evolving demands and expectations of its clients and stakeholders. According to our research, Coca-Cola HBC could expand its IM capabilities in three ways:

- Establishing an integrated set of Digital Twins for real-time, collaborative communication among suppliers, distributors, and retailers to analyze sales projections, production schedules, and potential supplier restrictions to optimize supply chain management. Additionally, they could monitor inventory, capacity, and shipment information on a 3D supply chain network map (immersive) to identify potential shipping delays and model workarounds to ensure efficient delivery.

- Introducing a smart packaging system that enables real-time tracking of a can‘s or bottle's position and inventory status (interactive). By using edge computing and data analytics, Coca-Cola HBC could optimize replenishment and routing decisions, shape demand by dynamically altering prices based on customer preferences, and improve overall profitability by reducing waste and maximizing resources.

- Leveraging AI-generated synthetic data to create more precise and responsive forecasting models to balance supply and demand. The use of synthetic data allows for adaptation to unforeseen occurrences like pandemics, natural disasters, and geopolitical shifts. By selecting the most environmentally friendly modes of transportation and routes, Coca-Cola HBC may improve production scheduling, transportation costs, and decrease carbon impact.

As a second example, General Motors (GM) has been using Process Simulate from Siemens to create an ergonomically efficient production line in a short period of time. GM must update its production line on a regular basis to accommodate for design changes of existing vehicles and production of new cars. For efficiency, engineers work remotely with a virtual reality device to immerse themselves in the designs. It helps understand manual assembly, hand clearances, operator movements, and operator’s line of sight. With this information, engineers can identify a problem at an early stage and solve it before the issue occurs in real life.

The team at GM is leveraging the motion capture possibility with Process Simulate where a line design engineer wears a suit and performs the activity that an operator will do in real life. The captured motions help the engineer understand what the awkward positions are and for how long an operator needs to be in that position. Engineers can ergonomically optimize the production line and reduce work related health problems.

Can GM advance in other areas with IM? According to our research, yes there are additional improvements to consider.

- All the motions captured will be combined with biomechanics (study of how the bones, muscles, tendons, and ligaments work together and have an impact on the fatigue of the operator). Future software will simulate the biomechanics of a specific operator performing tasks over a long period of time. Based on the simulation health issues can be identified accurately and solutions like customized Exosuits or tailored Personal Protective Equipment can be created for the operator.

- All these 3D models of operators can be converted into a Digital Twin and used to simulate realistic factories. GM has a large production workforce and a high number of robots in the line, making it important to check that operator movements would not be hindered by the robots. GM can make sure that operators and robots work in perfect synergy before commissioning the production line.

- Simulate and track the operator tasks in real-time. By tracking biomechanics live, precautionary measures can be taken before any work-related disease or accidents occur. The IM will help companies secure the health and happiness of their most important resource: HUMANS.

A third example of using the IM is at automotive OEMs. This industry has been using virtual reality and other digital technologies to optimize manufacturing and improve designs for some time. But now, these companies are faced with taking transformation to another level. Here is where the Digital Twin of Planning comes into play because it can simulate an entire production line accurately. Ultimately, it will help virtually plan entire factories before a single brick has been laid.

One OEM set its sights on creating an environment where the Digital Twin of Planning is neither based on trial and error nor on manual calculation or human experience but rather based on real life, real time, and accurate measurements from the factory shopfloor. The data from virtual simulations and the real production data run in parallel with all nonconformities being captured and assessed.

To support this, an IM architecture was developed ensuring that all authoring tools (as data sources) were connected to layers that allow for joint and connected simulation and visualization. The heart of these connections is a data layer and the management thereof in between authoring tools, simulation and visualization layers.

With the capability of simulating entire productions prior to any real undertakings, the OEM reduces the risk of new technology introductions, has stricter adherence to ramp-up curves, earlier concept validations, and overall, a more stable production process and better understanding of the behavioral model of a full factory. The Digital Twin of Planning and IM architecture also support lower levels of energy consumption, thus supporting sustainability, and to drive a more flexible, modular production where it becomes feasible to automatically, at the click of a button, select the optimal plant to produce a certain part or model.

Our research shows that this automotive OEM can further grow and create the Digital Twin of Operations which has the potential to improve simulations, including predictive maintenance and real-life digital control functionalities.

Don´t delay on the future of digitalization

While the Industrial Metaverse in its fully evolved state is still some way off, the time to start preparing is now. By embracing the evolution of the Digital Twin and taking proactive steps to prepare for the IM, organizations can position themselves to succeed in a future that will undoubtedly be shaped by these emerging technologies.

The IM is set to enhance the way companies operate. Improvements targeting the design and planning processes will drastically shorten product life cycle times, accelerate and simplify new product introductions, and increase productivity in planning processes. Not only will the Industrial Metaverse disrupt the planning of future business processes and production environments, but it will also optimize existing ones by reducing process times, improving product quality, freeing up cash by reducing inventory and completely changing the way we train and empower employees.

Those who don’t prepare for these changes, risk being left behind in the VUCA world.

Our expert

Author

When Two is Better than One: Digital Twins and Personalized Medicine

When Two is Better than One: Digital Twins and Personalized Medicine

Television shows and sci-fi movies have brought us Artificial Intelligence (AI) and 3D simulations for decades. While some of these creations were out of this world, ideas such as digital twins (used in movies such as Mission Impossible and Her) are very real and have demonstrated value in many industries. Digital twins are simulations of real-world processes and assets in the digital world.

With the need for faster, better, and more accurate treatments for patients, the healthcare and life sciences industries are turning to what a few years ago would have been unimaginable – personalized medicine powered by technology like digital twins to ensure patient treatment. In fact, according to one survey, 75% of U.S. consumers wish their healthcare experiences were more personalized … Patients would visit their healthcare provider more often if the experience was catered to them as individuals. This level of care can range from personalized treatment plans, to implants, to new drugs based on individual personal needs. As per market research by TMR, the digital twin in healthcare industry size stood at US$ 448.9 Mn in 2021 and is likely to surpass US$ 5.3 Bn by the end of 2031.

Digitalization, especially digital twins, can become a major enabler of personalized medicine. However, implementing digital twins is not easy. It requires substantial investment combined with a different digitally enabled operating model. As leaders in healthcare and life sciences are learning, it is unfeasible to introduce personalized medicine on a large scale, without changing the traditional engineering and manufacturing regime while utilizing digital twin technology. Additional costs and efforts for engineering, production, documentation, release management and post-market surveillance lead to significant investments for personalized medicine that are not cost-effective at scale within the current structures. Therefore, a targeted approach and an experienced technology partner are necessary to adapt traditional approaches and enable digital twin technology so that they create real business value.

To enable personalized medicine, reality needs to be simulated using digital twins along the whole value chain - from product development to production to supply chain management to performance / operations. This approach will increase efficiencies in engineering, enable small batch production scenarios at reasonable extra cost, allow for a faster time-to-market, and increase the security and quality of usage.

Digital Twins paving the way for Personalized Medicine

The digital twin integrates all data, models, and other information of a physical asset generated along its life cycle to predict and optimize performance. They can be demonstrated in three ways for healthcare and life sciences – product, production, and performance. Let’s look at these areas more closely.

Digital Product Twin

Whether you are designing and engineering a personalized / customized medical device (e.g., implant) or creating a personalized drug as part of a personalized treatment plan, two key factors are important:

- The effectiveness of the device or drug based on the personal conditions of the patients; and

- The safety of the patient.

With a digital product twin, both requirements can be simulated in the digital world through a digital representation of both the product and the key conditional factors of the patient. It then allows for an effective design, a fast and cost-effective design process, and immediate quality assurance. It represents the as-designed, as-built, and as-maintained product model along with properties and behaviors.

As new products are developed, time consuming and costly clinical studies are required to prove effectiveness and patient safety before regulatory approval and market introduction. However, by simulating the product and its functionalities during the R&D process, we can help focus on the most promising products to allow for targeted clinical studies and to avoid unnecessary real-world testing for non-effective or unsafe product variants.

Twinning in production

Producing personalized medical devices or drugs requires a different production environment. Gone are the large batches of drugs or devices and adapting to different batch setting requests. The new world is leading towards of a batch size one where the product doesn’t exist until the clinical and manufacturer requirements define what it should be. By using a digital production twin connected to the digital product twin, virtual commissioning of production allows for a cost-effective way to adapt production while enabling automated release documentation.

The digital production twins represent the entire plant layout and production process. In some cases, they might even enable a holistic digital product passport as an end-to-end fingerprint over the supply chain capturing key production data, and data of the pre-production steps of suppliers including the source and condition of the raw materials. Being able to trace a medical device’s condition back along the entire supply chain can contribute to greater transparency and product safety. Digital production twins allow companies to tackle supply chain and regulatory risks.

Me and my shadow: Digital Performance Twin

Once a personalized medical device is used by the patient, a flawless operation as well as perfect usability need to be ensured to enable the highest possible treatment and the best patient experience. A digital performance twin enables continuous monitoring of the device performance and usage with real-time validation against the intended design parameters. Anomalies in device performance or usage can be detected and corrected before harm occurs to the patient or the treatment becomes ineffective. A digital performance twin ultimately represents behavior and properties of a product during operation, maintenance, repair, and recycling.

Why is a Digital Twin important?

Digital twins open avenues for improved and targeted care and efficiency in healthcare or life sciences operations.

For example, by creating a digital twin of a hospital, operational strategies, capacities, staffing, and care models can be observed to determine what actions to take in any situation. Virtual models can assist in managing bed shortages, stopping or mapping the spread of germs, modifying staff schedules, and overseeing operating rooms schedules and maintenance. Digital twins can virtualize the hospital to create a safe environment, which tests the influences of changes on system performance without risks. This is important in healthcare as it enables informed strategic decisions to take place in a highly complex and sensitive environment.

At the same time, advances in medical imaging and wearables will have a great impact on the development of digital twins in healthcare. Medical imaging tools help to capture the state of the patient, its anatomy and physiology, and are one of the main inputs for mechanistic models. Wearables will be key to capture real-time patient data for monitoring and statistical models set up. This approach is already a reality with tools like Babylon Health’s Healthcheck App that captures health data into digital twins. It works with manually entered data such as health histories, a mood tracker, symptom tracker, and automatic capture from fitness devices and wearables like the Apple Watch. With this level of knowledge, the digital twin can provide basic front-line information or help guide priorities and interactions with doctors to address more severe or persistent conditions.

The pandemic also demonstrated that digital twins of a supply chain are critical to healthcare organizations to model relationships to understand better how to plan around new events, shutdowns, or shortages. For example, Siemens is working with Global healthcare company GSK to digitalize its vaccine development and production process. A key benefit will be much shorter development times for vaccines, allowing them to reach people faster and with the optimum quality. The digital twin plays a big role.

With digital twins, it is now possible to collect data to understand exactly what is happening in real time during vaccine production, enabling optimization of operations. It allows not only monitoring of complex processes, but also predicts how changes would affect them. In short, turning to digitalization helps speed things up at GSK.

Implementing Digital Twins - doing it right

Just as the Human Genome Project advanced our understanding of the human genome to 99.9%, digital twins can dramatically overhaul our abilities in discovery, research, and ultimately the way we treat patients. Some key learnings vital to successful digital transformation include:

- Life Science and healthcare companies need to understand which parts of their portfolio show potential for personalized medicine and which parts of their value generation (e.g., production, engineering) have possibility for digital twin applications.

- Parts of the portfolio and value generation that show potential need to be fully assessed to see which technology can work and what limitations exist.

- Once a promising application area that is technically viable is identified, a thorough assessment of required changes to processes, tools and the operating model in engineering, production, and the service department are required.

- Integration and smart scaling are key. You do not only need to technically integrate your tools but you also need to transform the whole organization and integrate the new technology into your processes, procedures, and the way people work.

And what´s next?

Digital twins can significantly improve enterprises’ data-driven decision-making processes. They are linked to their real-world equivalents and businesses use the digital twin technology to understand the state of the physical asset, respond to changes, improve operations, and add value to the systems.

Healthcare and life sciences are complex and closely regulated industries. Personalized medicine is one trend that is not going away. Therefore, companies need to consider a strong partner that understands not only the technology, but the specialties of the industries, and how to make this digital transformation a success.

Digital transformation does not end with digital twins. After all, a healthcare metaverse could combine the best elements of modern digital systems and traditional physical interactions. For example, using a virtual reality headset to practice surgical techniques using anatomical holograms – the physical training remains the same, but the virtual system allows for multiple attempts without creating harm.

Joining the digitalized world is not a question of why but it is a question of why not? That’s why leaders shouldn’t wait... acting today means staying competitive and profitable while meeting the growing patient needs.

Our contributors

Digital Twins for Real Estate

The Business Purpose of Digital Twins - Creating Intelligent Ecosystems in Real Estate

The real estate sector is in a period of reckoning in which digital transformation holds the key to the future.

Why is digitalization in buildings, campuses and districts so important – if not vital – to the wellbeing of the people who live and work in these? There are many reasons: increased flexibility, greater efficiency, enhanced communication, greater employee satisfaction – the list goes on.

So digital transformation has become a must, but this poses a number of challenges. According to a recent study, only 33% of commercial real estate companies feel they have the skills needed to operate a digitally transformed business. And just 45% plan to increase their investments in key technologies – like the cloud and digital channels.

Many organizations find it difficult to identify and track the ROI of digitalization initiatives and only 10% of executives state that they are able to measure the ROI of their digital initiatives, whereas 90% can’t. This is largely because teams will focus more on the ‘how’ and ‘what’ of the transformation e.g. the technology, which on their own might not amount to much, instead of the all-important ‘why’ – which is to unlock business value and future-proof operations. Digital transformation needs to have a holistic approach to lift a business to the next level of e.g. efficiency and prove that it’s worth the investment.

In the midst of this change, many new, digital-first Prop Techs are entering the market with a boosting venture capital spend of 31 billion euro alone in 2019 and technical innovation across the entire digitalization stack. This poses a challenge for established organizations to determine where to prioritize their digital transformation efforts and which technology to be used to reach their anticipated goal. And as they adopt new technologies and gather vast amounts of data from their customers, building sites, and more, companies aren’t always sure what to do with that information, or which potential they already have in their own pocket.

There are additional layers of change and complexity, like the shift to mixed usages buildings, creating living environments in cities with a lot of new functionalities at one location, or the increasing pressures for the real estate market to improve their impact on the environment where buildings alone contribute to 40% of carbon dioxide emissions globally. If they want to meet global net zero targets by 2050, real estate developers, managers and operators have to do everything they can to decarbonize real estate – that might include retrofitting existing buildings and rethinking how they build new ones and most important gain the transparency needed to define interventions of their existing asset portfolio.

In addition, Covid adds pressure on the real estate market to maximize usage of their property and put the highest priority on people who live, work and visit their assets and bring back life into the buildings via e.g. hybrid models, through hygiene concepts and new work space convenience which will become a default to increase productivity of the workforce and to attract new talents to grow the business.

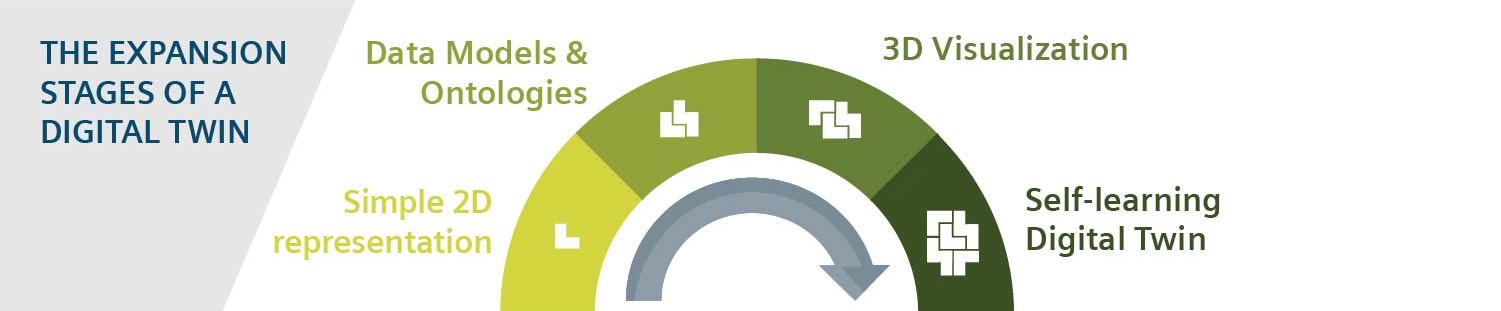

To address these challenges head on, as well as the very real challenges posed and highlighted by the current global crisis, real estate leaders need a more holistic strategy to transform their business with new stakeholders on the decision table across the C-Level of the organization like HR, Operations, IT, CDOs and other executives to play out the advantage of data rich technologies that provide a clear, big picture able to zoom into precise (near) real time data to enable effective decision making. This is where digital twins for intelligent environments like buildings, campuses and districts can play an important role – one that sets the real estate industry apart as it steps into the future. As the environment is diverse and customer needs are different, the shape of the twin always differs and can range between simple KPI dashboards to interactive 3D self-learning building representations.

Connecting the real and digital world with digital twins

In the real estate sector, digital twins act as a bridge between the real and digital world, where smart buildings and campuses feed information to a virtual environment, the digital twins enabled by the right digital strategy, IOT devices, system integration, cloud computing and analytical models. The digital twin can then use near real-time and historical data to simulate thousands of scenarios and help assess the impacts of different decisions at each stage of the real estate life cycle. As those intelligent ecosystems are continually evolving, the digital twin needs to adapt to new requirements, functionalities and KPIs, to scale through the digital transformation journey of each individual user.

Why digital twins are creating value for the real estate industry

Digital twins present a wealth of opportunities for the real estate sector, addressing many of the challenges that are changing the way they operate buildings to increase the ROI and to address the business properly. Each of the below listed categories needs to unfold in multiple use cases (applications, new processes, KPIs) to aggregate to a powerful tool supporting the business and its transformation journey.

- Comprehensive insight. A digital twin for a building, campus or district provides a holistic view into the collection of assets, and visibility on how well they work together.

- Enhanced health and wellbeing. Understanding tenants, visitors and employees also enables building managers and developers to focus on improving their comfort and wellbeing. This way, the building responds to the humans, and not the other way around. Having a strong IOT backbone and a scalable digital twin helps to enable such a living place by combining multiple data sources needed for a seamlessly functional intelligent building environment.

- Sustainability & move to NetZero. Digital twins offer insight into for example energy and water consumption to uncover optimization opportunities which enable real estate stakeholders to move towards carbon neutrality and create a positive impact for the environment and their own bottom line.

- ROI generation. With the right data, decision makers can choose approaches that enhance the return on investment and increase the value of the assets. This can become increasingly comprehensive through capturing all transition costs like process and tools, skill development or change management. But also keeping in mind costs that come with the technology stack in form of SaaS, support & maintenance, software development costs for applications, IoT platforms, communication & networks and IoT devices.

- Predictive maintenance. By analyzing data such as from the BMS, weather forecast, energy usage and other key factors, a digital twin can enable a proactive approach to maintenance across the building portfolio.

- Improved space usage. With a robust understanding of tenants and their habits, real estate managers can optimize how their space is used. This is particularly important for office buildings and mixed usage buildings in a post-COVID era.

As they address each of these elements, digital twins offer a tangible approach to digitizing process-driven operations – while also establishing a foundation for the real estate sector to address long-term global challenges.

The challenges being met head on by digital twins

As well as large-scale challenges that digital twins are helping the sector address, many of the obstacles that real estate professionals face day-to-day can be remedied by this data-rich technology.

Lack of insight to achieve ESG goals

With increasing pressure for the real estate sector to tackle ESG, a digital twin can offer full transparency into what processes and functions have the largest impact on environmental, sustainability and governmental KPIs.

With this information, owners and facility managers can define interventions to reach their anticipated goals across their portfolio. By integrating additional non-real estate data like traffic and weather, additional correlations can be drawn to improve their ESG KPIs.

Data silos everywhere

Segregated data is a challenge in most industries, but it’s especially true in real estate. With multiple, decentralized buildings, different years of construction, and even more stakeholders, insights are stored in different formats and locations, making it difficult to get a clear picture of the portfolio.

From BIM to Digital Twin

Taking a Building Information Modelling (BIM) of an individual building and taking it to the next level with a digital twin which connects several buildings and campuses involves the amalgamation of dynamic and static data from multiple sources. This enables the company or organization to access real-time data on how the building is performing according to KPIs from the strategic to the functional.

Consolidating data into a single pane of glass, a digital twin platform with multi-vendor system integration allows full asset transparency and advanced analytics that for example enables real estate owners to benchmark buildings, prevent system failure and enhance performance.

Unplanned asset downtimes

More often than not, building managers are responsive – not proactive – when it comes to addressing issues in their buildings. This negatively impacts the tenant experience and can prove a costly approach.

A digital twin can use machine learning models to predict when something will fail, prompting managers to book a contractor and giving them all the information they need about the item being updated. This approach saves money and time while also protecting the manager’s reputation.

Untracked asset performance

Real estate owners and managers will often set out objectives and targets for their portfolio of real estate, but it’s not always easy to track against those. Traditionally, they use static data to retrospectively measure performance — but that makes it difficult to adjust systems and processes in a proactive way.

Combining the real and digital world, new information can be extracted in near real-time alongside other external factors like weather conditions, occupancy scheduling, and human impact. This way, business owners can stay on top of performance and use it to make decisions around the rest of their portfolio.

Building the right, best suited digital twin

Technology is inspiring every industry to realize the art of possible and high-tech seems to solve every problem. Introducing ‘a digital twin’ and its embedded functionalities and applications without a clear business purpose is costly, will take time and in the worst case will not be accepted by operators, tenants or investors as it stays a digital tool without real business impact.

The most important goal is to define the human and economic benefits and balance those against technical possibilities to create the right digital twin solving the anticipated business needs via individual software development, pre-defined SaaS products /solutions or a mix of both.

Digital twins can be simple digital representations of one business problem or technically complex when covering a diverse ecosystem and a comprehensive set of KPIs, plus they can be resource intensive to build. In all cases they’re worth the investment when having the right strategy laid out for the business improvement needed.

Getting the digital twin right requires a few critical steps:

- Setting clear business goals that identify tangible use cases for the digital twin, clearly defining why a digital representation is needed and what it shall improve, by incorporating the existing data landscape to build up on an existing environment.

- Defining the ROI for the anticipated goal. This step is critical and includes a back-and-forth balancing business and technical requirements which leads to digital twin ‘strawman’.

- Designing the digital twin. Now high-tech comes in place to select the right technology for the right usage with a clear budget in threshold to ensure that the digital twin covers the business goals and gives the solution experts the boundaries needed to suite the digital twin into the business.

- Implement the twin. A critical factor for success is the first go-live of the twin in an agile mode to ensure all technical interfaces are set, but also to prepare the organization for their first transformational step potentially changing the way how operations are run, how transparency has been gained and decisions are made.

- Scale the solution. A digital twin is not a one-off. It’s a digital representation of the business and therefore needs to have the adaptability to scale and adapt along with the business itself. In step 1 this has been defined properly so scaling the twin across the real estate portfolio will need to be a natural step in the business strategy to start the journey of a digital transformation of the business.

Digital twins are a market differentiator. As the real estate sector faces a new era of digital transformation, this innovative, intelligent technology helps address a lot of the challenges that established organizations are navigating. This data-rich approach is key to proving the ROI of any change – digital or physical – in real estate. It also levels the playing field, bringing legacy and disrupting businesses together as they collectively tackle necessary changes in how complexes are built and operated. To top it off, digital twins have a significant impact on efficiency, cost reduction, operational intelligence, and decarbonization – all factors that will future-proof the sector as we head into the next decade.

Our contributor

Our industry leader

Applied Industry Analytics

Applied Industry Analytics

We provide targeted data and analytics solutions to clients across all sectors to drive digital insights and impact.

Leveraging data analytics and machine learning for strategic growth, innovation, and operational excellence

Data is an enabler for strategic business growth, innovation, enhanced profitability, and operational efficiency. With clean, accessible, and governed data, your organization can implement new use cases to create new services, gain deeper insights into your operations to solve the business challenges of today and tomorrow.

The application of data analytics, machine learning, and statistical analysis aims to address real-world industry problems, improve operations, reduce costs, increase efficiency, and enhance customer satisfaction.

Our experts provide support for your organization, from strategic data assessment and landscaping to developing data governance and hygiene approaches based on global best practices. We identify the "Minimum Viable Data" needed to release impactful use cases and services. We also provide all the enabling architectural and connectivity requirements to bring a coherent data proposition to life. We will support your organization step by step to compound the value of your existing digital enterprise estate and create data-driven outcomes that help your organization embrace and extend its digital maturity and offerings.

Explore our tailored portfolio to support your business needs

Unlocking applied industry analytics: from data baselining to IoT Digital Core

In applied industry analytics, organizations embrace a holistic approach to leverage data. It starts with data baselining, understanding existing sources, structures, and quality. Strategic data analysis focuses on essential elements for actionable insights. Robust data governance ensures integrity, security, and compliance. Applied analytics deploy cutting-edge tech for valuable insights. IoT integration enhances real-time monitoring and predictive analytics. These themes drive innovation and operational efficiency.

Data baselining, also known as data landscaping, is our approach to processing and visually organizing data in an intuitive and easy-to-understand way. This involves developing diagrams, maps, charts, and dictionaries to show the relationships between different data elements and entities. After identifying the appropriate data (see "Minimum Viable Data"), we process, prepare, clean, and align it for analysis. This typically includes data profiling, cleansing, and transformation to ensure accuracy, consistency, and completeness of the data.

We use strategic data analysis to identify and target our clients' Minimum Viable Data (MVD), which is the minimum amount of data needed to achieve a specific objective or goal. The concept of MVD is often used in agile development methodologies to quickly develop and release products by focusing on the minimum set of features required to meet customer needs.

Regarding the application of data analytics, MVD refers to the minimum amount of data necessary to gain insights or make informed decisions. This involves identifying the most important data variables, reducing data redundancy, and eliminating extraneous data points that do not contribute to the analysis.

The use of MVD can streamline the data collection process, reduce the cost and time required for data storage and processing, and improve the accuracy and relevance of the analysis. By focusing on the minimum amount of data required, data analysts and decision-makers can avoid information overload and being distracted by irrelevant or inconsequential data.

However, it is important to note that MVD should not be seen as a rigid or fixed requirement. As business needs and objectives change, the minimum viable data may also change, and additional data may be required to gain deeper insights or achieve more ambitious goals.

We employ data governance as the process of managing and ensuring the quality, availability, integrity, and security of an organization's data. We work with clients to define policies, procedures, and standards for data management, as well as assigning responsibilities for data management and ensuring compliance with regulatory requirements.

The data governance process typically includes the following steps:

- Defining data policies: Establishing policies that govern the management of data, including data quality, data security, data privacy, and data retention.

- Establishing data standards: Defining data standards that outline the rules for data collection, storage, and use, such as data formats, data definitions, and data validation rules.

- Assigning data ownership: Identifying data owners who are responsible for managing specific data sets and assigning data stewards who are responsible for ensuring the quality and accuracy of the data.

- Establishing data processes: Developing processes for managing data throughout its lifecycle, including data collection, data storage, data processing, and data dissemination.

- Ensuring data security: Implementing measures to protect data from unauthorized access, such as encryption, access controls, and data backup and recovery.

- Monitoring data quality: Regularly monitoring data quality to ensure that data is accurate, complete, and consistent.

- Auditing data compliance: Conducting regular audits to ensure compliance with regulatory requirements and internal policies and procedures.

- Continuously improving: Continuously reviewing and improving the data governance process to ensure that it remains effective and efficient in meeting the organization's data management needs.

Our approach is a true end-to-end process, from the initial identification of value through to the implementation of applied analytical solutions. We work with our clients from initial discovery to POC (Alpha) and MVP (Beta) to full-scale implementation and support.

Our analytics development process is a framework for designing, developing, and implementing analytics solutions for specific business problems or opportunities. The process involves several stages that build on each other to create a successful analytics solution. These include problem definition, data collection, data preparation, data exploration, modeling, evaluation, and deployment.

Overall, the analytics development process is iterative and involves multiple cycles of refining and improving the analytics solution. The key to success is to ensure that the analytics solution is aligned with the business problem and stakeholders' needs and that the insights generated are actionable and can drive business value.

The IoT digital core for industry is a framework for building out the value of data that customers already have. Integrating and exposing this data with ease, and creating value use cases and analytics without the focus on the technology, allows accelerators to quickly begin the value of data.

The IoT digital core and data use cases & analytics are two essential components of IoT technology. They work together to collect and analyze data from connected devices and sensors in real-time.

IoT Digital Core: The IoT Digital Core is the foundation of an IoT system. It consists of the hardware and software that manage the flow of data from connected devices to the cloud. The digital core includes the devices themselves, as well as the gateways and edge devices that are used to collect data and transmit it to the cloud. In addition to hardware, the digital core also includes software such as operating systems, security software, and data management systems. Instead of focusing on technology, this is an accelerated framework approach to bringing value from your data, with blueprint integration adapters, data models, and workflows.

Data Analytics: Once data is collected by the digital core, it is processed and analyzed using data analytics tools. Data analytics involves applying statistical and machine learning algorithms to identify patterns and insights in the data. These insights can be used to optimize industrial processes, improve product quality, and reduce downtime. Data analytics can also predict equipment failures and maintenance needs.

Together, the IoT Digital Core and Data Analytics form a powerful system for managing and analyzing IoT data. By collecting and analyzing data in real-time, businesses can gain valuable insights into their industrial processes and make data-driven decisions to improve efficiency, productivity, and profitability.

Latest Applied Industry Analytics insights

Our industry leaders

The Importance of Sustainability for Small and Midsized Companies

The Importance of Sustainability for Small and Midsized Companies

Transforming companies to address sustainability including saving the planet from climate change and resource scarcity are topics of concerns for businesses around the globe. Terms such as “decarbonization,” “sustainability,” and Environmental, Social, and Governance (“ESG”) can be heard in most boardrooms and on national TV.

But what if you are the owner of a small or midsized enterprise (SME)? What role should you play in sustainability? Is there something different that you must do since sustainability regulations might be white noise to you as you strive to continue your business and support customers despite supply chain shortages, pandemics, natural disasters, and global inflation?

Some may argue that SMEs are different than large corporations and don’t need to adhere to the same sustainability practices, but the need to be sustainably responsible must be part of every leader’s vision. For example, SMEs make up about one-third of the gross domestic product and employ close to 60 percent of the population in countries such as Austria, Germany, Switzerland, and the United States. However, they are also responsible for upwards of 70 percent of the environmental pollution caused by industry in general.

If sustainability strategy and implementation are done correctly, it can lead to value creation for your SME. But there are consequences if sustainability is not part of the long-range company vision. According to leaders at the Cambridge Institute for Sustainability Leadership, “firms that aren’t proactive on sustainability were in danger of being left behind.”

That state of being ‘left behind’ includes losing customers, talent, and in some extreme cases even the business.

Six steps for SMEs to be future ready now

Here are six fundamental activities that SME leaders need to do today to drive tomorrow’s success:

1. Lay the groundwork for sustainability transformation with transparency on the status quo.

It is essential to first understand where your company is regarding each aspect of ESG. As a research exercise, our team analyzed the sustainability maturity level of 20+ companies and found highly varying results with the majority (~75%) of the companies studied at an early stage of their sustainability journey. The lower ranking often equates to not having a clear vision or position on what the company wants to do with sustainability. In these situations, there are missing goals or no sustainability initiatives in place. Knowing where your company is with sustainability is the baseline from which to build the sustainability plan.

2. Understand the requirements of upcoming regulations for your company, customers, and suppliers.

Have you heard of the EU Corporate Sustainability Reporting Directive or the Supply Chain Act in Germany? Maybe you are familiar with the United States Security and Exchange Commission’s (SEC) new climate risk disclosure rule?

These are just a few examples of the many regulations in place or coming shortly that will impact SMEs. Even if reporting requirements target enterprises, SMEs are part of that supply chain and will need to meet certain standards to maintain their business.

Various studies have indicated that there is a lack of accountability and ownership for ESG in SMEs. This must change. Partnering with an experienced company that can screen regulatory changes and ensures that your company stays up-to-date in regulatory topics is a place to start. This will help your company identify risks earlier and take precautions instead of reacting to each regulation separately. SMEs must align with all counterparts across the entire value chain proactively, understanding as early as possible what they need to do to meet respective regulatory and customer requirements. Leaders may consider collaborating with a partner for regulatory questions especially if a high number of regulations apply to your specific business, i.e. if a company operates in different markets, has a broad product portfolio, or if the industry is highly regulated.

3. Embed sustainability in your company strategy.

A survey conducted by Commerzbank showed that 62% of small- and mid-sized companies in Germany do not have a sustainability strategy. (1) Another study found in Austria 37% of SMEs with 30-2000 employees have no sustainability strategy.

Embedding sustainability in strategy offers high potential for SMEs to react to increasing regulatory and stakeholder demand. To do this, you can compile the assessment of your status quo and any regulatory / stakeholder requirements. Then, translate the insights into concrete ESG goals and strategies relevant to your business and define specific action items to address key pain points. Business strategy development will be improved when planning sustainable initiatives.

There are also fines connected to non-compliance. SMEs risk missing out on business opportunities if they do not demonstrate a sustainability roadmap.

4. Show commitment to sustainability and connect with key stakeholders through shared values.

It would be game-changing for SMEs to not only embed sustainability into business objectives and mission, but also to communicate the status quo and goals transparently. When the vision, strategy, progress, and roadmap for sustainability are clearly defined and communicated, the company effectively establishes a sustainable brand that resonates with different stakeholders, thus convincing them to further engage with your business.

Sustainability activities should also come through in employer branding and marketing activities (e.g., social media, company website). One advantage of sustainable positioning is higher recognition and attraction for talent as young workers have indicated growing preference for mission-led companies. In 2021, research by IBM Institute for Business Value revealed that around 70% of potential employees are more likely to work for socially responsible or environmentally sustainable organizations.

5. Quantify ESG activities to make your success transparent.

One of the basics for a successful sustainability journey is to define suitable key performance indicators (KPIs) and track progress. Each industry will have its own ESG KPIs. However, there are some key fundamentals that can help any business shape its KPIs, including:

1. Understanding KPI requirements from regulatory bodies and stakeholders

2. Prioritizing KPIs, proving feasibility, and defining realistic targets

3. Implementing in alignment with ESG strategy and roadmap

Many SMEs are often unaware of the connection between ESG KPIs and possible financial support available to them. One source of funding assistance that has become very attractive and is spreading across the globe, is sustainability-linked loans (SLL). According to Refinitiv data, SLL issuance tripled its previous record to reach a volume of $717 billion in 2021. For each SLL, lending institutions typically offer 5-10% margin discount to borrowers if they meet certain KPIs, which could be either third-party ESG ratings, or specific KPIs applicable to the borrowers’ industry, country, or company size.

An example of a company taking advantage of this financial support is a mid-sized waste management company in Germany that secured an ESG rating-linked loan, from which they benefit with loan discounts whenever they receive a rating upgrade from the external rating agency. (2) Another family-owned German luxury cosmetics business managed to link an SLL with its annual CO2 emissions reduction target. (3)

6. Embrace digitalization because it is the key to sustainability success.

Efficient sustainability transformation can only be possible with implementing digital transformation.

Digitalization helps with real-time collection of data to identify problems that cause waste or unnecessary energy loss. Using digital technology correctly has the potential to reduce a company’s carbon footprint and drive optimization in energy consumption.

Another key benefit of digitalization for SMEs is in Sustainability Reporting adherence – a key component of transparent sustainability. Strong capabilities in digital tools and data analytics, as well as automation of data collection and analysis, can help reduce efforts in reporting activities. Digital tools can also support the monitoring and visualization of KPIs.

It's important to note that whether the SME has the technology skills in house or partners with a specialist, there needs to be investment in, and an understanding of, advanced technologies like Artificial Intelligence (AI), Industry of Things IoT, and Blockchain and how they might benefit the organization.

One example of a company that made the investment and saw the benefits of digitalization is a Spanish automotive supplier that saved energy through data analytics. A cloud-based application gathered data every one or two seconds from plant machinery in individual production plants around the world collecting approximately 800 million data points daily. This gave the company access to data on electricity and gas consumption in real time. Thanks to reduced energy consumption, the company has been able to lower its CO2 emissions by 15%. In 2016, the company emitted 14,000 fewer tonnes of CO2 than the previous year, and by 2017, it had saved a massive 16,000 tonnes. That’s the equivalent of taking approximately 3,200 cars off the road.

Despite the possibilities of success, a study found that while 96% of global decision makers view digitalization as ‘essential to sustainability’ only 35% of surveyed firms have implemented Industrial Internet of Things (IIoT) at scale. While this demonstrates that the value of digitalization and sustainability is recognized, it also shows that the adoption of relevant digital solutions to enable better decisions and achieve sustainability goals needs to accelerate particularly in the manufacturing, energy, buildings, and transportation fields.

Putting it all together

It is important that SMEs view sustainability as a competitive advantage, not a burden.

It is a “must do” not a “nice-to-have” add-on. The bottom line – sustainability impacts every business no matter the size, geographical location, or financials.

As we also read in the Harvard Business Review, prioritizing sustainability initiatives not only leads to a desirable work culture and increased employee engagement but also highlights the importance of employees as critical stakeholders in addition to shareholders.

Demonstrating sustainability success leads to new opportunities to reinvent, differentiate, reposition, expand, and (re)claim market territory. With the size of the SME market globally, the cumulative effect of small changes in SMEs can make a real difference to the environment.

Additional Sources:

(1) According to a 2021 study by Unternehmerperspektiven, an initiative of Commerzbank.

(3) Babor secured a sustainability-linked loan facility from Deutsche Bank in 2021.

Our expert

Digital Twins and Industrial Metaverse

Digital Twins and Industrial Metaverse

Tap optimization potentials by implementing Digital Twins and Industrial Metaverse applications

Optimization solutions for planning and operations with Digital Twin and Industrial Metaverse

Our expert team helps clients identify and implement relevant use cases for Digital Twins and the Industrial Metaverse, leveraging Siemens Advanta's domain and technology knowledge. We offer simulation approaches, immersive environments, and collaborative solutions with photorealistic rendering to optimize planning results and operations. Our focus is on solving specific challenges, not just digitalization for its own sake. We also guide clients in establishing scalable and future-proof IT architectures for real-time access to relevant data, empowering their Digital Twins and Industrial Metaverse applications. Partner with us for efficient utilization of these cutting-edge technologies.

Explore our tailored portfolio to support your business needs

Digital Twin

Predict and optimize performance with Digital Twins along the product life cycle

Our cutting-edge approach utilizes virtual environments, including simulation tools and real-time data from the physical world, such as real-time locating systems, to enable our clients to predict and optimize business processes and production execution throughout the entire product life cycle - from design and engineering to production and servicing.

Building your Digital Twin: Our 5-step approach

With our specialized 5-step approach, we help our clients develop and implement a tailored Digital Twin solution to address their specific business challenges. Leveraging our extensive network within and outside of Siemens Business Units, we provide swift support in implementing the required tools and technologies, ensuring our clients achieve their objectives efficiently.

Industrial Metaverse

Elevate your Digital Twins to the next evolutionary step - the Industrial Metaverse

By enhancing Digital Twins with immersive, interactive, and collaborative features, a whole new level of benefits can be unlocked. While this may require effort, the advantages are significant, including faster decision making, improved planning results, and optimized production operations, among others.

Implementing the Industrial Metaverse goes beyond technology

While adopting the necessary tools and technology is essential, we believe it is the final step in implementing an Industrial Metaverse use case. For us, developing a cohesive strategy for the Industrial Metaverse, upskilling the workforce, and building strategic partnerships with key technology vendors are equally, if not more, crucial for successfully embracing the Industrial Metaverse.

Latest Digital Twin and Industrial Metaverse insights

Our industry leaders

Contact Us

Contact Us