Organizational Transformation Management

Organizational Transformation Management

Deep expertise on how to transform organizations

Siemens Advanta supports throughout the transformation starting with definition of the aspiration level and levers, setting up the governance and – striving for sustainable change – consulting and supporting in all aspects of the execution.

Siemens Advanta aspires to support its customers from the beginning of their transformation journey and goes beyond standard change management. Based on a sound organizational understanding and domain know-how, transformation targets are continuously checked against formal and informal structures and capabilities. In the execution phase, our customers benefit from vast (methodological) experience that enables us to set up the right governance and achieve sustainable change by putting your people in the center of our efforts.

- Organizational analysis against transformation targets

- Change impact analysis

- Governance and project/ program set-up

- Transformation/ change roadmap including comprehensive stakeholder management

- Realistic transformation targets

- Organizational alignment through all hierarchies

- Clearly evaluated change impact for each target group

- Fast, comprehensive, and monitored adoption through integrated change management

Our industry leaders

Cost & Value Engineering

Cost & Value Engineering

Providing detailed analysis to identify the optimal approach to source, manufacture and design in innovation and sustainability while reducing cost.

Vendigital as part of the Siemens Advanta organization, drives accelerated cost and value engineering transformation through data.

Cost & value engineering provides another lens, beyond traditional procurement levers, through which to tackle cost challenges. Using a bottom-up approach, we support the process of aligning costs to strategy as well as optimizing the costs of current products and helping to shape future products – ensuring the benefits are maximized across the entire product lifecycle.

-

Value Analysis Value Engineering (VAVE) – assigns a cost to the value or function of a product. By optimizing the relationship between the two, we ensure that products are not over-engineered or under-designed but instead are engineered for the task while keeping costs down.

-

Should cost modelling – we take a bottom-up approach to produce accurate granular level cost calculation for a product or service. These cost models help future procurement cost negotiations, allowing our clients to conduct fact-based negotiations with suppliers.

-

Make versus buy – we help clients understand the true cost of making something in-house versus buying from a supplier. This enables them to make data-backed decisions that support better profitability, stronger business resilience and greater competitive advantage.

-

Design to cost – we support clients to design products with the total cost of design and manufacture in mind. This gives our clients the understanding they need to design a product that is not only fit for purpose but one that can be produced at volume for a profit.

-

Lifecycle costing – accurately profiling the costs of a product over its entire life, from its inception to its decline and end-of-life costs, to understand the total costs involved and successfully forecast and plan for the future.

-

Carbon footprint calculation – we take an in-depth look at the carbon profile of products and their parts to identify those with the highest emissions, before modelling different scenarios and recommending specific actions to help reduce the overall emissions.

- Battery manufacturing assessment – our battery manufacturing assessment helps clients get more transparency around the commercial impact and investment decisions they need to make to ramp up production in battery manufacturing and provides key insights for manufacturing scalability – shaping the art of the possible for tomorrow’s gigafactories.

-

Engineering the product to the right level – we advise on what our clients’ target cost should be for a particular product, component, or the business as a whole. This ensures that a product or component is not over-engineered, therefore reducing spend.

- Enhanced supply chain relationships – we help clients forge better relationships with their suppliers by getting all parties to deal in facts, ensuring transparency and therefore helping reduce cost by getting the right quality of the right part from the right supplier.

- Lower cost and emissions through design - having an accurate data-led cost or carbon calculation allows our clients to make design decisions based on a product’s overall lifetime costs or carbon profile before it enters production.

Our industry leaders

Procurement

Procurement

Data-driven optimization of procurement strategies and functions to accelerate cost transformation and deliver on-going cost savings.

With over 50% of many companies’ outgoings allocated to procurement, optimizing this area of the business is critical to controlling the cost base in any industry. From helping our clients understand the whole life cycle cost of an item or service to generating greater value from the supplier base, we support businesses to improve their procurement processes.

-

Cost of ownership – we provide an understanding of a product's whole lifecycle cost, revealing hidden expenses within different stages to support informed decision-making on future procurement.

-

Strategic sourcing – we enable clients to make informed decisions when engaging suppliers by evaluating all of the factors that contribute to suppliers’ delivery, such as their true pricing, workflows and supply locations.

-

Process and capability improvement – analyzing how a company carries out its activity and what resources and expertise are available to support it, with the objective of determining where productivity, efficiency and quality of output can be improved.

-

Demand management – a forecasting process which establishes a critical link between the marketplace and a company’s activity with the aim of ensuring demand is met via the most cost-effective and profitable approach.

-

Category management – involves segmenting spend into different areas which enables opportunities for consolidation and focus. This takes procurement beyond the purchase of individual goods to create a longer-term strategy.

- 3rd party cost reduction – we combine data analysis with our expert knowledge of procurement to create clear spend benchmarks across suppliers, locations and categories. From this we can rapidly identify 3rd party savings opportunities.

-

Understanding the whole lifecycle cost – the true cost of an item or service involves more than its price at purchase. Using data-driven insights, we can uncover these costs to formulate a value-focused future strategy.

-

Greater value from the supply base – we identify and select suppliers, aligned to business objectives, that will provide the highest value at the lowest possible cost while building long-term relationships with each supplier.

- Delivery of sustainable cost reduction – by carrying out an in-depth analysis of a company’s procurement processes and implementing data-driven strategies, we deliver cost reductions that can be maintained over the long-term.

Our industry leaders

Business Strategy

Business Strategy

We unlock your business's potential by successfully solving new, unexpected, and complex challenges. Our approach involves consistently evaluating and refining all of our activities to ensure optimal benefits for your business.

- Market Exploration: Identifying which market forces and trends to address

- Strategy Development: Determining what to do given your current position

- Strategy Operationalization: Implementing your preferred strategy

- Creating awareness of market trends, such as threats and opportunities

- Developing strategic options by leveraging your strengths and weaknesses

- Deriving an actionable approach to achieve your targets

Our industry leader

The Importance of Sustainability for Small and Midsized Companies

The Importance of Sustainability for Small and Midsized Companies

Transforming companies to address sustainability including saving the planet from climate change and resource scarcity are topics of concerns for businesses around the globe. Terms such as “decarbonization,” “sustainability,” and Environmental, Social, and Governance (“ESG”) can be heard in most boardrooms and on national TV.

But what if you are the owner of a small or midsized enterprise (SME)? What role should you play in sustainability? Is there something different that you must do since sustainability regulations might be white noise to you as you strive to continue your business and support customers despite supply chain shortages, pandemics, natural disasters, and global inflation?

Some may argue that SMEs are different than large corporations and don’t need to adhere to the same sustainability practices, but the need to be sustainably responsible must be part of every leader’s vision. For example, SMEs make up about one-third of the gross domestic product and employ close to 60 percent of the population in countries such as Austria, Germany, Switzerland, and the United States. However, they are also responsible for upwards of 70 percent of the environmental pollution caused by industry in general.

If sustainability strategy and implementation are done correctly, it can lead to value creation for your SME. But there are consequences if sustainability is not part of the long-range company vision. According to leaders at the Cambridge Institute for Sustainability Leadership, “firms that aren’t proactive on sustainability were in danger of being left behind.”

That state of being ‘left behind’ includes losing customers, talent, and in some extreme cases even the business.

Six steps for SMEs to be future ready now

Here are six fundamental activities that SME leaders need to do today to drive tomorrow’s success:

1. Lay the groundwork for sustainability transformation with transparency on the status quo.

It is essential to first understand where your company is regarding each aspect of ESG. As a research exercise, our team analyzed the sustainability maturity level of 20+ companies and found highly varying results with the majority (~75%) of the companies studied at an early stage of their sustainability journey. The lower ranking often equates to not having a clear vision or position on what the company wants to do with sustainability. In these situations, there are missing goals or no sustainability initiatives in place. Knowing where your company is with sustainability is the baseline from which to build the sustainability plan.

2. Understand the requirements of upcoming regulations for your company, customers, and suppliers.

Have you heard of the EU Corporate Sustainability Reporting Directive or the Supply Chain Act in Germany? Maybe you are familiar with the United States Security and Exchange Commission’s (SEC) new climate risk disclosure rule?

These are just a few examples of the many regulations in place or coming shortly that will impact SMEs. Even if reporting requirements target enterprises, SMEs are part of that supply chain and will need to meet certain standards to maintain their business.

Various studies have indicated that there is a lack of accountability and ownership for ESG in SMEs. This must change. Partnering with an experienced company that can screen regulatory changes and ensures that your company stays up-to-date in regulatory topics is a place to start. This will help your company identify risks earlier and take precautions instead of reacting to each regulation separately. SMEs must align with all counterparts across the entire value chain proactively, understanding as early as possible what they need to do to meet respective regulatory and customer requirements. Leaders may consider collaborating with a partner for regulatory questions especially if a high number of regulations apply to your specific business, i.e. if a company operates in different markets, has a broad product portfolio, or if the industry is highly regulated.

3. Embed sustainability in your company strategy.

A survey conducted by Commerzbank showed that 62% of small- and mid-sized companies in Germany do not have a sustainability strategy. (1) Another study found in Austria 37% of SMEs with 30-2000 employees have no sustainability strategy.

Embedding sustainability in strategy offers high potential for SMEs to react to increasing regulatory and stakeholder demand. To do this, you can compile the assessment of your status quo and any regulatory / stakeholder requirements. Then, translate the insights into concrete ESG goals and strategies relevant to your business and define specific action items to address key pain points. Business strategy development will be improved when planning sustainable initiatives.

There are also fines connected to non-compliance. SMEs risk missing out on business opportunities if they do not demonstrate a sustainability roadmap.

4. Show commitment to sustainability and connect with key stakeholders through shared values.

It would be game-changing for SMEs to not only embed sustainability into business objectives and mission, but also to communicate the status quo and goals transparently. When the vision, strategy, progress, and roadmap for sustainability are clearly defined and communicated, the company effectively establishes a sustainable brand that resonates with different stakeholders, thus convincing them to further engage with your business.

Sustainability activities should also come through in employer branding and marketing activities (e.g., social media, company website). One advantage of sustainable positioning is higher recognition and attraction for talent as young workers have indicated growing preference for mission-led companies. In 2021, research by IBM Institute for Business Value revealed that around 70% of potential employees are more likely to work for socially responsible or environmentally sustainable organizations.

5. Quantify ESG activities to make your success transparent.

One of the basics for a successful sustainability journey is to define suitable key performance indicators (KPIs) and track progress. Each industry will have its own ESG KPIs. However, there are some key fundamentals that can help any business shape its KPIs, including:

1. Understanding KPI requirements from regulatory bodies and stakeholders

2. Prioritizing KPIs, proving feasibility, and defining realistic targets

3. Implementing in alignment with ESG strategy and roadmap

Many SMEs are often unaware of the connection between ESG KPIs and possible financial support available to them. One source of funding assistance that has become very attractive and is spreading across the globe, is sustainability-linked loans (SLL). According to Refinitiv data, SLL issuance tripled its previous record to reach a volume of $717 billion in 2021. For each SLL, lending institutions typically offer 5-10% margin discount to borrowers if they meet certain KPIs, which could be either third-party ESG ratings, or specific KPIs applicable to the borrowers’ industry, country, or company size.

An example of a company taking advantage of this financial support is a mid-sized waste management company in Germany that secured an ESG rating-linked loan, from which they benefit with loan discounts whenever they receive a rating upgrade from the external rating agency. (2) Another family-owned German luxury cosmetics business managed to link an SLL with its annual CO2 emissions reduction target. (3)

6. Embrace digitalization because it is the key to sustainability success.

Efficient sustainability transformation can only be possible with implementing digital transformation.

Digitalization helps with real-time collection of data to identify problems that cause waste or unnecessary energy loss. Using digital technology correctly has the potential to reduce a company’s carbon footprint and drive optimization in energy consumption.

Another key benefit of digitalization for SMEs is in Sustainability Reporting adherence – a key component of transparent sustainability. Strong capabilities in digital tools and data analytics, as well as automation of data collection and analysis, can help reduce efforts in reporting activities. Digital tools can also support the monitoring and visualization of KPIs.

It's important to note that whether the SME has the technology skills in house or partners with a specialist, there needs to be investment in, and an understanding of, advanced technologies like Artificial Intelligence (AI), Industry of Things IoT, and Blockchain and how they might benefit the organization.

One example of a company that made the investment and saw the benefits of digitalization is a Spanish automotive supplier that saved energy through data analytics. A cloud-based application gathered data every one or two seconds from plant machinery in individual production plants around the world collecting approximately 800 million data points daily. This gave the company access to data on electricity and gas consumption in real time. Thanks to reduced energy consumption, the company has been able to lower its CO2 emissions by 15%. In 2016, the company emitted 14,000 fewer tonnes of CO2 than the previous year, and by 2017, it had saved a massive 16,000 tonnes. That’s the equivalent of taking approximately 3,200 cars off the road.

Despite the possibilities of success, a study found that while 96% of global decision makers view digitalization as ‘essential to sustainability’ only 35% of surveyed firms have implemented Industrial Internet of Things (IIoT) at scale. While this demonstrates that the value of digitalization and sustainability is recognized, it also shows that the adoption of relevant digital solutions to enable better decisions and achieve sustainability goals needs to accelerate particularly in the manufacturing, energy, buildings, and transportation fields.

Putting it all together

It is important that SMEs view sustainability as a competitive advantage, not a burden.

It is a “must do” not a “nice-to-have” add-on. The bottom line – sustainability impacts every business no matter the size, geographical location, or financials.

As we also read in the Harvard Business Review, prioritizing sustainability initiatives not only leads to a desirable work culture and increased employee engagement but also highlights the importance of employees as critical stakeholders in addition to shareholders.

Demonstrating sustainability success leads to new opportunities to reinvent, differentiate, reposition, expand, and (re)claim market territory. With the size of the SME market globally, the cumulative effect of small changes in SMEs can make a real difference to the environment.

Additional Sources:

(1) According to a 2021 study by Unternehmerperspektiven, an initiative of Commerzbank.

(3) Babor secured a sustainability-linked loan facility from Deutsche Bank in 2021.

Our expert

Revving up Automotive Manufacturers for the Circular Economy

Revving Up Automotive Manufacturers for the Circular Economy

According to the World Economic Forum (WEF), the automotive industry is “dramatically overshooting its estimated carbon and resource budgets.” Automotive manufacturing is a major contributor to a global industry that requires the extraction and processing of more than 100 billion tons of materials every single year, which causes 90% of biodiversity loss and water stress, and about 70% of the world’s carbon dioxide emissions.

Moving from a linear to a circular economy will reduce this burden on the planet’s resources, minimize waste, and give the most pioneering manufacturers a competitive advantage. The WEF predicts that circular economy will yield up to USD 4.5 trillion in economic benefits by 2030.

However, to benefit from the circular economy, automotive manufacturers need to get ahead of the curve on future regulations, sustainability goals, and customer expectations.

All signs point to a circular economy

The circular economy replaces the traditional extract-create-dispose linear economy with a regenerative model, built around recycling and re-use of natural resources. By maximizing the lifetime of finite resources, it reduces consumption and waste. This is particularly relevant for the automotive industry as it moves to replace the internal combustion engine vehicle (ICEV) with battery electric vehicle (BEV).

As the International Energy Agency (IEA) notes, BEVs require more than six times the mineral inputs of ICEVs. Considering the need to electrify the world’s existing stock of

1.3 billion ICEVs by 2050, with the total global vehicle stock projected to grow to 2.2 billion by 2050, such resource requirements are neither sustainable, nor any longer bearable.

But the imperative to move to a circular economy is not exclusively an environmental one. Global supply chain challenges have created shortages in semiconductors, leading to sales losses of more than 30% for automotive manufacturers.

Further pressure is approaching in the form of EU regulation. Brussels is set to impose minimum material recovery rates for battery raw materials such as nickel, lithium, cobalt, and copper in 2025, with increasing mandatory minimum levels taking effect in 2030 and 2035. According to the Nickle Institute, “Any company placing batteries on the EU market will have to comply with the manifold requirements in the regulation, independent of whether they operate in Europe or elsewhere in the world. All players will have to ensure that their upstream processes in mining and refining the materials, chemical processing, conversion into cells as well as assembling the batteries comply with the targets and requirements set by the legislation.”

Manufacturers should not wait to implement circularity. The circular economy offers a means of gaining a significant competitive edge in a market where nearly two thirds of customers are willing to pay more for sustainable products.

The time to kick off your journey towards circular economy is now. Buckle up. It may be a bumpy ride.

Navigating the road to circularity

By offering traceability through data transparency, digital transformation will provide the means to achieve true sustainability in automotive manufacturing. However, to achieve actual business value and leverage digital solutions in the best way, some key imperatives must be considered.

1. Creating full transparency over your vehicle’s lifecycle

Assets like the digital product passport, as introduced by the European Commission’s European Green Deal and Circular Economy Action Plan, will be essential tools for developing resource-efficient and environmentally friendly products in the future. These product passports will need to incorporate a wealth of data about how a product is built, used, and maintained, and how it may be altered throughout the different phases of a circular car’s lifecycle.

Automotive manufactures must collect data from every aspect of the value chain to create data maps and a connected digital ecosystem. This will give manufacturers and other stakeholders a fully transparent view of emissions, resource use, and sustainability.

Creating full transparency and traceability throughout the vehicle lifecycle with, for example, a digital vehicle twin will be vital in not only complying with regulations but also in reaching carbon net zero and in enabling new business models. To get there, organizations must capture digital twins for both their vehicles and the respective components and parts materials. This will help functions within an organization to extract the relevant data needed for R&D, compliance, procurement, and strategy to maximize the individual impact and make well-informed decisions.

2. Innovating new and profitable ways to recover strategic materials

The industry needs to find new ways of securing primary materials so that demand can be balanced, and materials are readily available. Shortages of semiconductors, magnesium, and wire harnesses have been exacerbated by recent challenges in the global supply chain, and they serve to highlight the difficulties that exist in guaranteeing the quality, security, and reliability of strategic materials.

The way to overcome future shortages of strategic materials is to act within an ecosystem. Partnerships with downstream players, such as dismantlers, recyclers, or shredders, can help to secure components and materials for product manufacturing by increasing the ratio of secondary materials. If automotive players work together within their ecosystem, they can create digital solutions that enable efficient dismantling and recycling processes.

Digitalization and automation have the power to transform the dismantling stage to enable product lifecycle extensions, as well as innovative strategies for remanufacturing, repurposing, or recycling. In short, these actions will help create closed loops of components and materials manageable on digital marketplaces, thus embodying the very idea of a circular economy.

3. Identifying and implementing circular business models

Companies need to evaluate both the opportunities and dangers of transforming into new business models. While circularity can help automotive players tap into new business, changing the mechanics and performance KPIs of revenue generation has its pitfalls and can often meet resistance within an organization. For that reason, automotive manufacturers must carefully design their transformation to circularity.

The design must consider the entire lifecycle of the vehicle to identify new perspectives on value which requires increased transparency. Innovating your business model requires defining future customer profiles in detail as well as respective monetization details. In a next step, businesses need to evaluate what aspects within the business ecosystem can move towards a circular business model. New revenue streams might arise through extending the vehicle lifecycle, by building networks in platform models, or from “as-a-Service” (aaS) models to increase the usage of a single product. Extended vehicle lifetimes, for example, can help drive different perspectives across an organization. Assessing the effect of circularity actions on existing business models can help identify new opportunities to create value for customers across the automotive ecosystem. Partnering with organizations that offer access to existing circular business models and aaS models can be a good starting point when it comes to analyzing which new business opportunities make sense for customers. Automotive players can then prioritize use cases and define a respective roadmap.

As an example of what’s possible, Chinese automobile manufacturer NIO has already pioneered the battery-as-a-service model through battery swapping. Under this model, customers don’t own the battery but pay for electricity and battery use either on a pay-as-you-go basis or by subscription. This means that increased battery range – by itself environmentally undesirable and more costly – is no longer an issue and opens the market for more economical and environmentally friendly BEVs.

4. Leveraging Design-for-Circularity for products

There is little doubt that a combination of future regulations and customer expectations will steer companies in the direction of secondary material quotas. This can only be achieved by reassessing existing product design and architecture.

Original Equipment Manufacturers (OEM) must analyze the impact and footprint of a vehicle along the entire product lifecycle to gauge the current circularity of their products, components, and materials. Such an analysis of product lifecycles can help manufacturers formulate a product vision, value proposition, detailed product circularity requirements and future product concepts.

By implementing a modular architecture for vehicles, manufacturers can enable efficient maintenance and dismantling processes encompassing reuse, remanufacturing, or recycling, all of which are prerequisites for a truly circular approach. The dismantling of components and the separation of materials – for example, from wire harnesses and interconnectors – will be facilitated by standardizing material compositions, which is likely to deliver higher quality secondary materials.

It is worth remembering at this stage that innovations in product design and architecture have an impact across entire organizations, so senior management must lead the process for it to be successful. This leadership includes providing close support for changes in skill sets and job descriptions. Outside of an organization, these innovations also impact the whole lifecycle and, therefore, require cross-stakeholder partnerships with all partners and suppliers within the ecosystem.

Better resilience and sustainability found with circular economy

From what we have seen, circularity has the power and potential to deliver enhanced resilience and represents the key to a sustainability success story within the automotive industry.

A circular model can provide value chain resilience and offer protection against the sort of supply chain dangers that have hit the industry so hard. Increased resilience will enable organizations to mitigate operational risk and business interruption by designing new strategies for sourcing material resources and components. Keeping recycled resources within the automotive ecosystem frees manufacturers from resource dependency and shields operations from the inevitable future scarcity of raw materials.

The circular vehicle approach can deliver competitive advantages too. First movers will take a pioneering role in automotive manufacturing and will be in a position of thought leadership when it comes to use cases and business models in the automotive ecosystem. They will be more successful in attracting and retaining forward-thinking talent, and their improved sustainability will help to attract investment. Furthermore, circularity will allow manufacturers to develop new circular business models, access new markets, and diversify customer segments.

A circular approach allows for a sustainable business set-up putting first movers ahead of the curve when it comes to future regulations around emissions and material use. Slow movers risk non-compliance and potential fines.

It can also drive concrete business target setting and performance while giving OEMs the ability to leverage long-term visions to steer and monitor the relative success of circularity models in different business functions and regions.

Closing the loop with digitalization and data

OEMs, suppliers, and ecosystem players need to make strategic choices to mitigate future obligations and disruptions. But they are well advised to take full advantage of the immediate and long-term benefits of transitioning towards a circular economy that digitalization can unlock.

The goal is to close the end-to-end loop and maximize the full business potential of reusing materials and components, and to minimize industry’s impact on the planet. But to mitigate the risk, effort, and cost involved in something that has a deep impact on every aspect of a company’s operations, OEMs can kick off their transition to circularity by focusing on specific components or materials and building upwards from there.

Right now, external momentum and stakeholder requirements are dictating the future of the automotive industry. Players still can shape their position in the race towards a sustainable future. A holistic circularity mindset is key to taking a proactive and progressive role and maximize societal and business value.

Now is certainly not the time to apply the brakes.

Free whitepaper

Identifying digital service opportunities to unlock business potential in the digital age. Download our whitepaper to learn how to develop comprehensive data strategies to identify new business opportunities and prepare your company for the digital age!

Our expert

Expert

How Digital Twins Deliver the Holy Grail of Connected Supply Chains

Building Resilience: How Digital Twins Deliver the Holy Grail of Connected Supply Chains

Listen to the blog here:

For CEOs of industrial manufacturing firms, one of the biggest concerns arising from the COVID-19 pandemic has been supply chain disruption. One study put the average cost to large businesses (those with revenues above USD 1bn) at around USD 184m in 2021.

Throughout 2020, the number of organizations experiencing 20 or more supply chain disruptions increased by a factor of six, according to the Business Continuity Institute’s 2021 Supply Chain Resilience report. This ranged from the Suez Canal blockage to container pileups in Shanghai and other major ports. If this wasn’t enough, ongoing climate change issues as well as geopolitical changes were the missing cherry on top. The same report found that the proportion of senior management showing a medium or high commitment to supply chain risk rose by nearly 10 percent to 82.7%. This goes to show that these global influences have the effect of transforming supply chains into revenue assurance drivers rather than cost reduction pillars.

Faced with this increasing volatility, uncertainty, complexity and ambiguity, the number one priority for sector leaders is to build resilience into the supply chain. Due to the pandemic leaders’ priorities shifting to business continuity and their realization that connectivity is the golden ticket, the challenge lies in a successful way to accomplish this.

The Holy Grail – connectivity across the supply chain

The global supply chain market is expected to experience a compound annual growth rate of 11.2% from 2020 to 2027 – a market value surge from USD 15bn to USD 37bn. With the added speed bump of supply chain disruptions, it’s time to build resilience into your supply chain, and business leaders are reaching for plentiful and readily available technological developments to do so. Currently, the IIoT-based solution showing the most potential when creating a resilient supply chain is the use of digital twins to mimic supply chains and productivity networks.

In recent years, the digital transformation of supply chains has made them increasingly dynamic and complex. Catalyzed by the pandemic and other previously mentioned supply chain hurdles, manufacturers have sought out new ways to optimize supply chains to ensure transparency. To do so, in-depth understanding and visibility of the entire end-to-end ecosystem of suppliers and customers – their needs, strengths, weaknesses and potential risk factors – is the Holy Grail.

This ideal of a fully connected ecosystem providing real-time data starts by connecting your own supply chain. Only once you have complete visibility of your own end-to-end operations, connection with the wider ecosystem can be achieved, enabling you to create a holistic overview and transparency from customer to supplier.

Based on this holistic overview, you need to decide on your own business goals and adjust your digitalization strategy accordingly. Easier said than done? Not necessarily. The important thing is not to drown in the ocean of possibilities and to keep your eye on your business goals, letting them dictate the level of detail your digital solution requires.

Digital twins – the kick starter for connected supply chains

It’s estimated that up to 93% of all IoT Platforms will contain some form of digital twin capability by 2027. So what exactly is a digital twin? And how does it tie in with a connected supply chain? To put it simply, a digital twin is a virtual representation of a physical product or process. By feeding it with data, it can be used to model the current situation in real time, test ‘what if’-scenarios for the future and, in some instances, even provide ‘best practice’ to the modelled disruption. As such, it provides predictive insights, highlights areas of weakness or potential failure and enables timely preventative action.

By incorporating the latest technical innovations (eg multi-physics simulation, AI, data analytics and machine learning), digital twins can demonstrate the impact of usage scenarios, environmental conditions and other variables to improve the resilience of a supply chain. The digital twin is therefore the ultimate goal in connecting your supply chain, yet you need to learn to walk before you can run. Start by determining the digital journey most adequate for reaching your business' set goals and drivers. Luckily, there are a few maturity levels you can reach before chasing the Holy Grail of the digital twin, and there is likely a data solution for every organization and budget.

To provide visibility and transparency on an operational level, applying a digital map or model might suffice, as it provides basic insights into your operations. However, if you want to leverage data to simulate and explore various possible scenarios and the effects of changes before implementing them in the physical supply chain, a digital shadow might be the best approach. However, only a digital twin can create enough insights to enable real-time connection and provide concrete simulations for operational, tactical as well as strategic decision making.

How to implement a digital twin fit for your goals

The key to realizing this ideal scenario is leveraging the correct data in the correct way by the correct people. However, as with any form of digitalization, there are several factors to consider when starting the journey to executing a digital twin.

Firstly, it’s crucial to always have your goals in mind: the business outcome you want to achieve should be the foundation for your decision as to which data model to use. For certain organizations, it may not be necessary to apply an end-to-end digital twin at the very beginning of your digital transformation journey. Trying to navigate through the buzzwords and promises from solution providers and staying true to your core needs is therefore an important first consideration. Applying technology just for the sake of applying technology is never the solution!

Secondly, a digital twin is only as good as the data it gets fed. Therefore, you need to gather useful data and that’s the tricky part. When creating the digital twin, connecting your internal data is advised, as this is the data that’s readily available to you. However, it’s important not to fall into the trap of data overload, which can result in too many insights slowing down and clouding the decision-making process. Once you have an internal connected supply chain in place, you can start reaching out to your ecosystem to further increase connectivity. It’s essential to take the time to understand relevant data management solutions for your business goals and ecosystem.

Everybody knows that data is the new gold in business, and companies are often reluctant to give it up lightly. This results in a potentially complex process of connecting your full ecosystem, as you need to convince all stakeholders about the joint value that can be created through sharing knowledge and creating transparency. As soon as they’re fully connected and sharing their data, you can collectively create the most detailed digital model possible, which will benefit everybody along the chain.

However, in reality it’s unlikely that every member of your ecosystem will share the data needed to simulate a complete supply chain digital twin, but that does not mean the end of the line for your digital twin journey. The good news is that there is a sophisticated workaround to help you overcome this particular roadblock: artificial intelligence (AI). Through AI, it’s possible to model the missing data and thus fill in gaps in your data lake. Furthermore, other data sources can be fed into AI to derive expected impacts to the supply chain from striking events, for example the news of a flooding in a particular region in the world can be overlaid with your supplier base and the digital twin can preempt potential impacts and solutions.

Everybody knows that data is the new gold in business, and companies are often reluctant to give it up lightly.

Making the process match the insight

Now that your data is in place and connected, the true benefit of a digital twin emerges. Real time connection and seamless data flow will enable direct transparency of your data, and customized visualization, dashboards and alerts will allow for rapid decision making. The only question is, will your decision-making processes be able to keep up with this increased speed of knowledge?

Data digitalization and process optimization need to be harmonized, as data without a process is useless, and a process without data is inefficient. Future supply chains will be a combined learning network of humans and technology, so alongside building your digital twin, it’s important to invest in the creation of a flexible workforce willing to adapt its skillset to facilitate a bionic supply chain. After all, the most powerful intelligent network is still the human mind, and it’s fundamental in deriving and acting on the benefits of a supply chain digital twin.

Enabling and benefitting from the factor of the future

When applying connected supply chains in the industrial manufacturing environment, it is important to shed light on how their connection to the green, lean, and digital factories of the future will look like. In this specific context, the successful creation of supply chain digital twins depends on the quality of data from every factory, warehouse, or nod within the supply network. This means that it is best practice to successfully develop digital twins of your factory in the first place. This will make the trick for the whole network as data could be provided seamlessly.

At the same time, it is crucial to understand that the factory of the future and its successful operations heavily depend on seamless data flows, processes, connectivity, and agility on a large scale in order to ensure individual productivity, robustness, and delivery excellence. Ever changing markets, customer requirements and supply disruption can only be managed sustainably by building agility and reactiveness into the mix. The supply chain digital twin can be the dealmaker in this context enabling the transparency needed beyond one’s own facilities. In the end, the factory of the future, being green, lean and digital in nature, is both enabler and benefactor from the creation of a supply chain digital twin. Seamlessly, connected supply chain can build the basis for factories and whole networks to decarbonize operations.

Unlocking the potential of supply chain digital twins

Increased connection and digitization open the possibility of creating supply chain digital twins, but it’s not actually the digital twin that creates the value for your business. A digital twin is simply the vehicle you need to enable a fully connected supply chain, and the strategic connection with your individual business goals is the key that makes your vehicle perform. As a result, your entire ecosystem will gain a competitive advantage.

Siemens Digital Industries Logistics (DI LOG) has already paved the way towards a comprehensive digital supply chain twin with their end-to-end resilience solution. This platform helps both Siemens and its partners to proactively manage supply chain and operations based on real time tracking and data-driven alerting functionalities for all involved parties within the network.

Free whitepaper

Based on our unique experience in digital factory environments, we identified several company as well as use case specific factors to make the groundbreaking decision between edge and cloud. Download our whitepaper and learn which factors to consider when unlocking the full potential of your IIoT journey!

Our experts

Author

Digitalization with Purpose

Digitalization with Purpose – Uncovering Data to Create Utility Stakeholder Value

All data is not equal and data access alone will not deliver value to your enterprise.

For a simple statement, it is one that carries significant consequences. For every bit and byte of data exchanged from central, enterprise platforms to edge and connected devices or assets, there is a specific cost and value to the business and its stakeholders.

At a unit level the TOTEX (total expenditure, including upfront capital outlay and ongoing operational costs) associated with each byte of data may be small; however, with the exponential growth of data, related costs will continue to rise.

While that rise may not be as steep as the growth in data volume overall, the continuing fall in the cost of data storage is flattening out, meaning businesses need to look more closely at how they manage their data to keep costs under control.

The accumulation of data in isolation does not yield outcomes or deliver business returns. Data must be consolidated and consumed to turn it into value.

Data offers new opportunity

So how should data be viewed strategically, if not as a direct source of value but one with an inherent cost? Ultimately, data is an enabler – it enables use cases and applications, which solve the business challenges of today and support the ongoing advancement of an organisation for its stakeholders.

The potential value of data is equally reflected within the art of the possible – the emerging topics and innovative ideas that are yet to be conceptualised by the best and brightest of our global society yet to be brought to market which will increasingly rely on data to disrupt and progress.

Clearly data and information provide a basis to construct value and insight, which would be inaccessible without it. The emerging data-driven solutions of today and tomorrow will be a key facet within the necessary evolution and transformation of our utilities, cities and societies, as part of a net carbon zero future.

However, Rome was not built in a day and digitalisation represents more of a journey than a destination. It is vital, therefore, that we acknowledge that there is no silver bullet when it comes to digital and data enablement.

Challenges will be witnessed throughout the journey of individual organisations, evolving based on the maturity and capability of the existing systems, strategy and personnel at their disposal.

Understanding digitalisation challenges for utilities

As we uncovered during my last blog, global spend within the Industrial Internet of Things (IIOT) is rising. In 2020 it was valued at USD 216.13bn, 20% of which is directly attributable to the energy sector. Investment at this scale will create transitional risks for utilities, but these can be mitigated with a prudent approach to business digitalisation strategy, planning, implementation and management.

As data volumes grow throughout the energy sector, there will be an unequivocal need to provide robust cyber security, auditability, standards adherence etc, and to control processes for stakeholder access to data. With individual platforms and systems, this can be challenging enough; when considering the wider direction of enterprise IT/OT integration, these headaches will be compounded.

A greater focus upon platform and system integration will increase the pressures on legacy systems to scale and meaningfully participate within an increasingly open digital environment. It is not too far-fetched, therefore, to suggest that there will be a push from both internal stakeholders and external suppliers to procure new, digitally native, application rich products and systems which can critically scale.

This increases the risk of stranded assets throughout the enterprise estate, both today and tomorrow. For example, how confident are businesses that software and products procured today will scale and grow with your organisation, aligned to your respective digitalisation strategy, throughout the mid-to-long term?

The sunk cost of data

Stepping away from technology, challenges also emerge when considering the sunk cost of data and its management, not just in storage and communications, as noted previously, but also in terms of the digital fluency of a workforce.

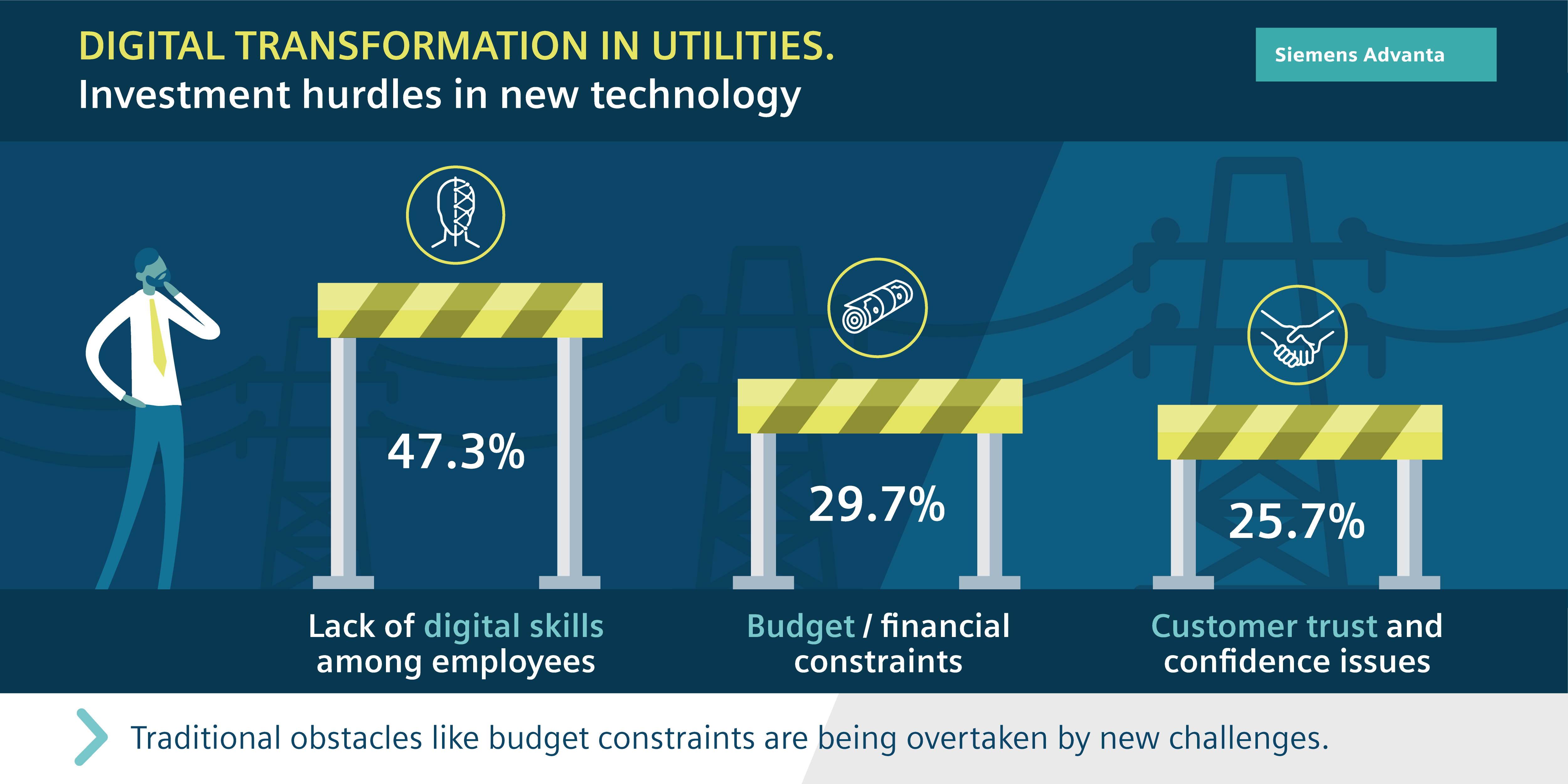

Tellingly, 47.3% of European transmission and distribution operators questioned in IDC's 'Utilities Core Business Transformation Survey 2021' confirmed that a lack of digital skills amongst employees was the largest internal challenge when investing in new technology. In comparison, the second highest challenge was budget and financial constraints, capturing 29.7% of the respondents’ concerns.

Then consider the challenge associated with determining the business impact of these investments. How frequently is Return on Investment (ROI) calculated and evaluated within digital procurement? How is this tracked throughout the operational lifecycle of the system?

Furthermore, how are the associated Environmental, Social and Governance (ESG) benefits monitored? These are aspects that are becoming increasingly important within the push for meaningful change in terms of reduced in carbon consumption over the coming decade. If businesses are unable to accurately document determine these required outcomes and benefits ahead of procurement up front, it is highly likely such KPIs will not be monitored nor realised during the lifecycle of the solution.

These points contextualise some of the typical challenges faced by utilities as part of digital transformation programmes. It is increasingly clear that the success of digitalisation initiatives depends on the provision of a client-orientated solution and outcomes, rather than potentially siloed digital products and offerings.

Avoiding pitfalls – how can digitalisation be de-risked?

Regardless of macro similarities, no two utilities are the same. Each business requires results consistent with its strategic direction, encompassing the underlying enterprise estate.

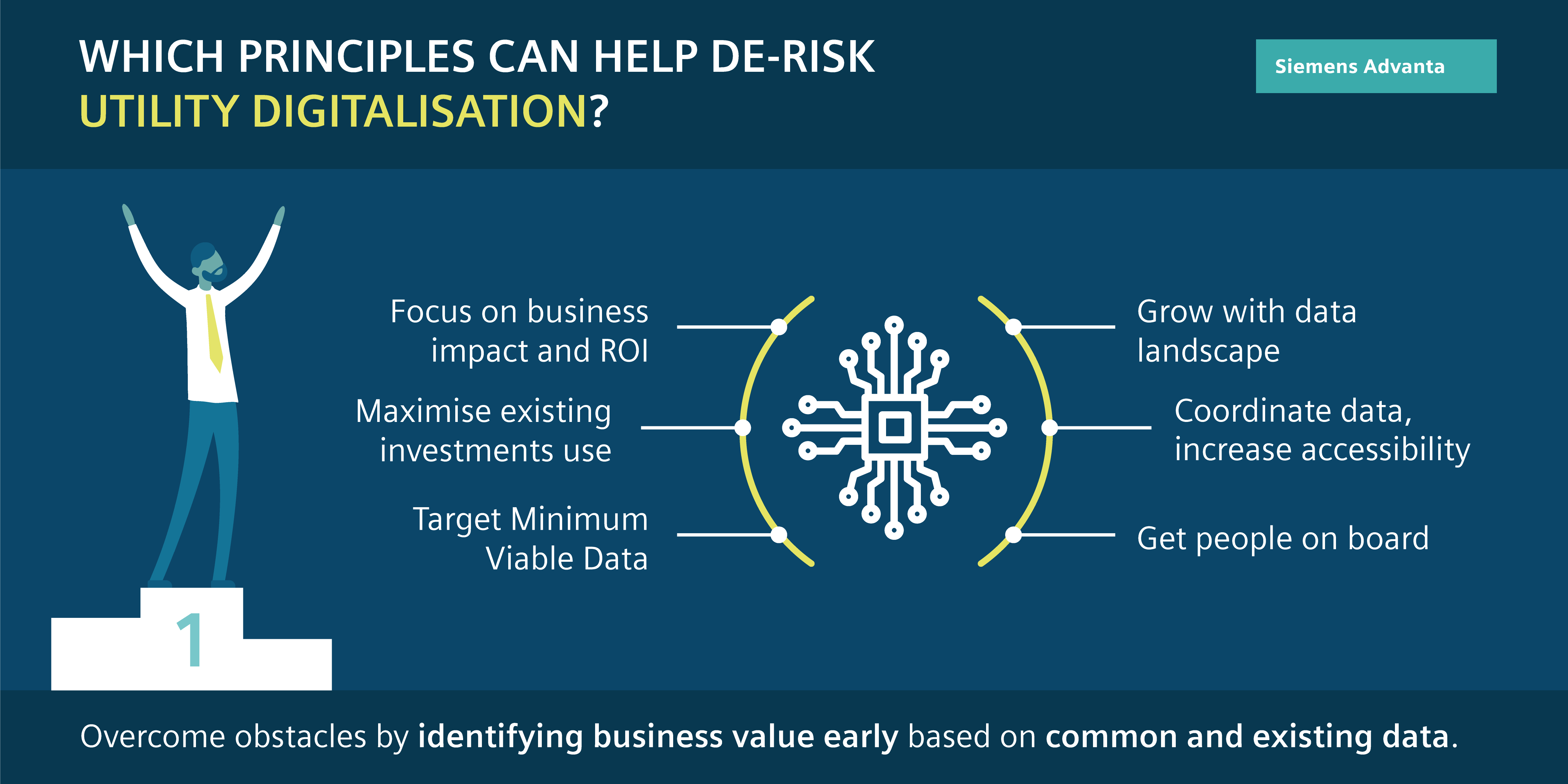

A client-driven solution goes some way to addressing nascent risk, though equally important is that solutions are underpinned with best-in-class common values – an effective set of guiding principles. Guiding principles offer consistency in approach, incorporating decades of best practice to minimise inherent risk within complex delivery.

Focus on business impact and ROI – All things data and digitalisation have inherent cost but this need not be a barrier to progression. The supporting business case for each investment should demonstrate where and how value can be created throughout the organisation.

Transparency in terms of target ROI and ESG benefits is critical because these elements provide justification as part of a robust business and investment case. Documenting how a utility company will benefit against its individual operational and strategic KPIs is a must.

Maximising the use of existing client investments – Throughout the operational lifecycle of any system there will be the need to maintain and even extend or enhance – activities which bear consequential cost. Driven by client need, building around and upon existing core systems to focus efforts within the enterprise IT estate can maximise existing capabilities and skills throughout the business, whilst limiting investment in new technologies.

If, for example, core systems can be enhanced to sanitise valuable data for wider use, this is likely to reduce investment cost in the enabling efforts and associated spend, thus improving ROI when creating new data-driven value.

Target Minimum Viable Data (MVD) – If not all data is equal, the task of prioritising which data offers most utilisation potential and consistency to support impactful use cases and applications is a vital activity. Determining what data exists, and what is accessible, creates a bespoke data landscape for your business – the MVD baseline.

Grow with your data landscape – As digitalisation is a journey rather than a destination, generating the MVD baseline to rapidly enable value with accessible data is critical. As your business and its ecosystem of increasingly connected technologies and digital personnel develop, so can the MVD baseline itself.

Therefore, providing a mechanism through open and scalable APIs for example, to integrate additional data from existing or emerging sources is essential to enrich and unlock additional digital value.

Coordinate data and increase accessibility – In collating a reusable MVD baseline, the opportunities to increase transparency and structurally open access to internal business stakeholders (subject to relevant access and governance requirements) becomes increasingly compelling.

How could the business benefit with an increasingly transparent approach to inter-departmental data access? What business challenges could be solved in new and innovative ways? In post-COVID operations, could data access and transparency support social cohesion for remote staff and increase digital fluency of the workforce?

The recent Gartner CDO Survey suggests it could. According to the survey, data and analytics leaders who increased data sharing led teams that were 1.7 times more effective at showing demonstrable, verifiable value to stakeholders.

Get your people on board – Early buy-in from employees, from the conceptualisation to implementation stages, helps to mitigate the scepticism often felt within a business in times of change. As presented within this Siemens Advanta blog, it is important to consider that digital transformation can often be as much a cultural transformation as it is a technical one.

Early engagement of your staff in the journey itself will help determine native digital fluency throughout the business, supporting the identification of internal experts, plus those areas that require future training and development.

These principles are constructed upon time-proven best practice and decades of solution implementation experience, underpinned by common sense. They are designed to directly reduce the risk and effort associated with data-led value enablement.

Embedding these principles supports the goals of early identification of business value based on common and existing data, and minimising enablement cost and business disruption in terms of systems and personnel alike. Consequently, these principles can be directly mapped within a wider strategic digital transformation approach, known as the ‘Digital Core’.

What is digital core?

Digital Core is a term occasionally used in the industry to describe technology platforms and applications that support business transformation, enabling organisations to address the needs of nascent and evolving markets considered within the digital economy.

Central to our Digital Core thesis is the consideration that existing and legacy systems cannot and will not be replaced overnight. Certainly, there will be times when operational systems reach the end of their working life, fail to integrate or even scale, at which point strategic product replacement will lead the way.

However, it is reasonable to assume that the constellation of operational systems in place throughout today’s modern utility landscape is likely to broadly reflect the enterprise environment in operation towards the end of the decade.

Therefore, to our team at Siemens Advanta, the Digital Core represents a mindset and approach, as much as technology and solution.

The Digital Core enables facilitates transformation; its adoption enables businesses and their stakeholders to build upon existing investments and extract data from operational core systems with focussed investment, to create new business value, underpinned with a clear business rationale. This, in essence, is harnessing the data that is being created and stored today throughout your organisation.

Digital core: systematic engagement and analysis

From a methodology and engagement standpoint, the Digital Core requires a baseline of technologies and systems which are strategically relevant over the mid-to-long term for a client. The theory is that each will represent the anchor for digitalisation initiatives over the coming years.

We consider the data from these core systems to be of principle value, as it is likely to be increasingly consistent and even enhanced, throughout a given time horizon, thus worthy of accessing for repetitive re-use.

Analysis of these core systems enables the creation of the MVD baseline, an activity that identifies what data and information exists and documents what is subsequently accessible today from these core systems. This environmental analysis of strategically and operationally relevant systems documents the data landscape and digital maturity of each core system.

Additionally, robust engagement sets out to understand and document the challenges faced by clients. In discussing business pain points and framing strategic and operational hurdles, it is feasible to derive data-driven resolutions in the form of new use cases and applications. Each of these can be subjected to cost-benefit analysis to calculate independent ROI.

Furthermore, this analysis includes consideration of the typical input data expected to bring individual use cases to fruition, tying the value directly back to the enabling, underlying data itself.

A gap analysis follows, assessing generated/accessible data from the business against highlighted use cases and input data. Any significant gaps can be either addressed via business change management to trigger additional data discovery or, where relevant, with targeted access to third party data, such as Metrological data. Armed with this insight, use cases could be reprioritised based on the MVD baseline and cost to supplement or extend. The outcome of this consultative process is to derive a common MVD landscape, which encompasses the following elements:

- MVD baseline – an overview of the data generated within the business from identified key systems, acknowledging which is and is not accessible to the business.

- Business challenges and resolutions – highlighting defined use cases alongside the common data required to enable each.

- Data gap analysis – available data versus use case comparison.

- ROI review – framing cost-benefit of key use cases from existing business data

As a consolidated activity, this gives a robust insight into the digital environment of any client, documenting how current data can address key challenges and create new value when enabled via the digital core.

Digital core: a client-driven solution

The Digital Core is not only a consulting activity but also the provision of a client-orientated solution. Tasked to access the MVD baseline from core business systems, it facilitates the creation of impactful use cases via a reusable and accessible integrated solution.

In creating a common, reusable and accessible data framework or MVD baseline, the intention is to enable client stakeholders to rapidly ideate, test and develop parallel data-led innovations. At every step of the Siemens Advanta Digital Core journey, value is created, either in analysis and understanding or with rapid prototyping and testing of ideas based on common data.

Depending on the respective requirements of each business, the form of the digital core solution will change. This is to balance the need for on-premise versus cloud technologies and for creating a single source of truth, like the master data of the business data versus a reflective data extract from core systems.

Once available, this promotes wider internal access to useful data, away from critical business systems, with governance factored into the solution. Thus, the need to really understand what data you have, where it came from, where it goes, security implications and its quality is satisfied. Such technical considerations will be explored further in a later blog.

As the digitalisation journey progresses, the MVD baseline can be extended with additional, richer data and information, compounding the enabling value of data held within the digital core.

In some regions, such as the UK, there is even a push towards ‘presumed open data' from the energy sector. This involves requiring that utilities, amongst others, reveal data to external parties, with the ambition to foster whole systems thinking and innovation to address sustainability and energy-related challenges.

The digital core methodology and solution accommodates even such a progressive take on data sharing, whilst providing governance and internal value creation simultaneously.

Delivering value from digitalisation should not be held to ransom over big data aspirations. Using a common or emerging MVD baseline to demonstrate quick wins in the form of a Proof of Value and Minimum Viable Products will promote longevity and acceptance of the broader digital transformation initiative.

Streamlining investment to deliver greater returns

According to a Siemens Advanta HBR pulse survey, 80-90% of respondents can’t or don’t accurately measure ROI for digitalisation initiatives. Given this, it is somewhat unsurprising that between 60% and 85% of digital transformation initiatives have failed. You can find more detail in our white paper, Internet of Things: From Buzzword to Business Case.

The paper spells out the direct costs associated with IoT/digitalisation initiatives, including applications, platform/solution, communications and devices/assets. It also quantifies the transition costs that align to the business and its adoption of new technologies.

Transition costs include the processes and tools, skills and personnel development that go alongside change management – all critical factors when considering the true cost of digitalisation.

A realistic ROI assessment will not yield a singular outcome. However, when considering variable uncertainty ranges within the calculation, the credibility of the results increases dramatically, as shown in the white paper.

The ROI analysis can, therefore, be enhanced when adopting a specific lens towards global utilities, offsetting the direct and transition costs against benefit created for the business.

As part of an activity called ‘360 business impact reflection’, analysis considers how data access and new use cases will impact the business. It addresses individual or shared challenges throughout internal departments with, for example, cost savings, efficiency benefits and improved KPI adherence.

This task includes the effort to prioritise and analyse common KPIs consistent with many utilities worldwide, based on the respective organisations. Examples include:

- Planned network interruptions

- Unplanned minutes lost

- Number of faults

- Inspection and maintenance cost

- Network reinforcement and refurbishment

- Asset health

- Customer satisfaction and complaints

- Cost to serve

- Time to connect

- Environmental management

These KPIs align within broad strategic pillars for utilities, which commonly include:

- Delivering a safe and reliable network

- Improving environmental impact

- Improving network connections

- Enhancing customer satisfaction

- Supporting vulnerable customers

360 business impact reflection in action

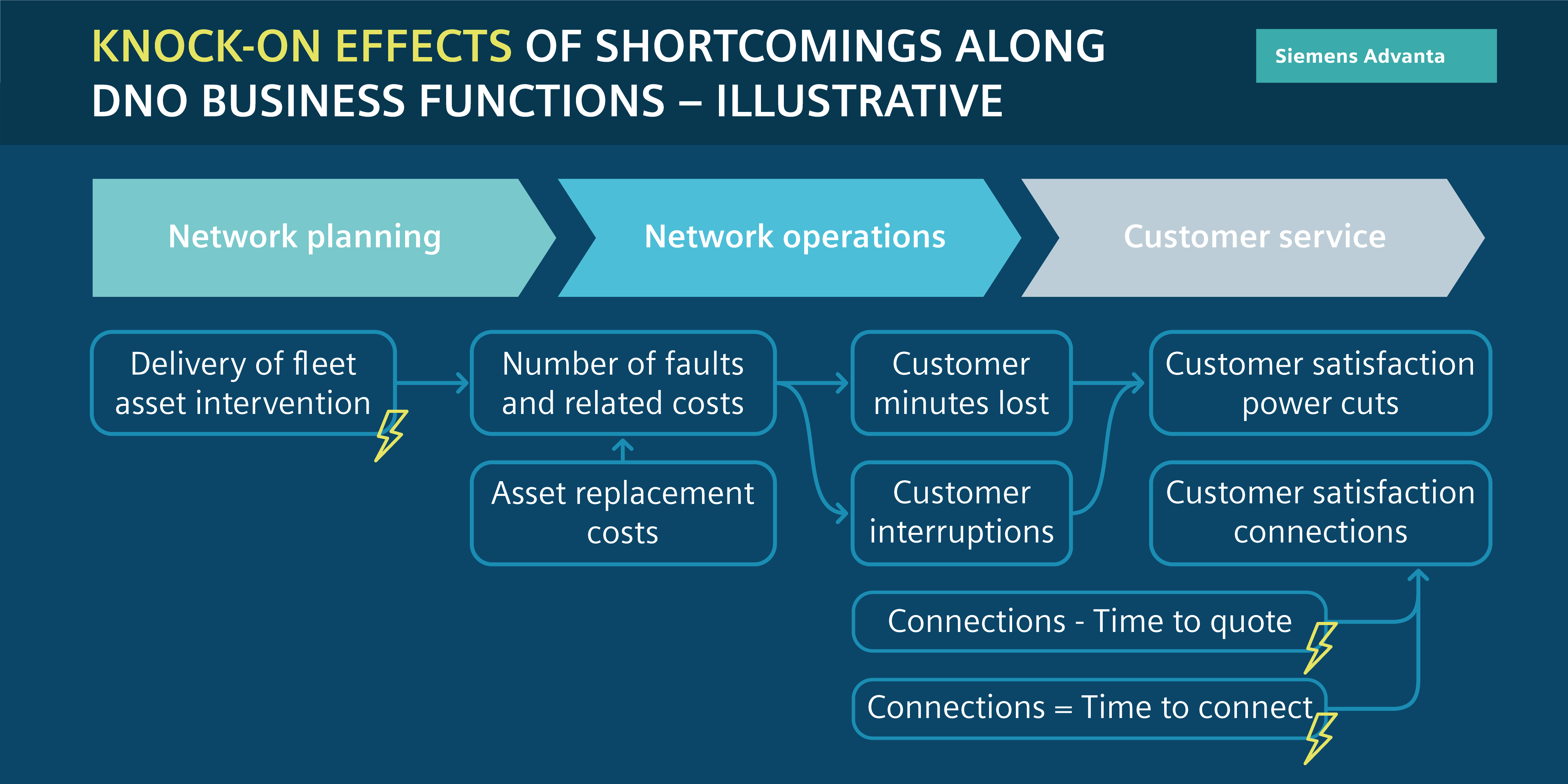

To explore the concept of 360 business impact further, let us take a specific example: heightened vulnerability of network assets due to sub-optimal network planning. In this example we’ll consider three key departments of the utility: 1) network planning, 2) network operations and 3) customer services.

- Suboptimal network planning can intrinsically increase the risk profile of the asset fleet throughout the network. 360 business impact reflection considers the effectiveness of asset intervention programmes, how asset risk is determined and the replacement/upgrade of each asset managed.

- The outcomes of this shortfall roll into network operations. Higher asset risk is likely to increase the number of faults and related costs of the network, potentially decreasing the operational lifetime of fleet assets and in turn increasing asset replacement cost.

- With increased faults come increased outages, impacting the customer in terms of minutes lost and supply interruptions. These factors are likely to come back to the customer services department, which must respond to stakeholders, both customers and regulators, as to the network performance.

- Such topics can additionally be reflected in the time to quote and connect of the connections department.

(Digital Core) Process + Solution = Outcomes

The cause and effect of decisions and activities is a constant within any operational environment and, as noted previously, digitalisation is not a silver bullet. However, what can be provided is richer, more powerful insight, using data from existing systems, manifested within new use cases, to solve current and future business challenges. As an inclusive and accommodating methodology, understanding the specific circumstances of each client, the Siemens Advanta Digital Core ensures a financially appropriate outcome is realised with clear investment rationale.

By linking the enabling and value creation activities, built upon existing client systems, and addressing specific business challenges using current and available data, it drives and unlocks impactful use cases as part of a tailored solution for your business.

Free whitepaper

Discover the Internet of Things and the challenges that need to be solved in a digital transformation. Get insights how to create value when optimizing processes or generating new business models out of data.

Our expert

Eight Key Challenges for Digital Transformation to Succeed

Eight Key Challenges for Digital Transformation to Succeed

According to the Harvard Business Review, Siemens is among the top global players for digital transformation along with firms such as Amazon, Netflix, Microsoft, and Intuit, to name just a few. Since the dawn of the digital age, Siemens has been at the forefront of digital automation, vertical software leadership, and, more recently, the Internet of Things (IoT). This means that as an organization, Siemens offers unique insights into the challenges that need to be met for digital transformation to succeed, because the company already stumbled over several roadblocks itself. If digital transformation strategies are not put in place, or enacted poorly, then companies will fail. After all, around half of Fortune 500 companies have disappeared since 2000. The same fate could befall any organization that fails to meet the challenges for digital transformation today. What are they, and why are some not as obvious as others?

Obvious business challenges of digital transformation

First, it will be best to look at some of the most obvious business challenges with digital transformation. They are a good benchmark of what every organization will need to overcome to succeed in the digital future. They are also a good starting point to think about digital transformation before the less obvious challenges start to become more evident.

One – Developing new services and products

Perhaps the most obvious of all challenges for digital transformation involves identifying new services and products to support a business's core portfolio. New customer demands force businesses to develop new products and services. However, companies often struggle to find the right solutions that fit their original business strategy and product portfolio. To take a highly successful example, Netflix began as a DVD and Blu-ray rental-by-mail firm in 1998, a service it still offers. Netflix's commitment to digital transformation in the 2000s meant it initially offered an online ordering system for its physical products. Soon, however, it had completed its digital transformation into one of the world's most popular digital streaming services, not just offering on-demand access to its customers but producing exclusive content for it as well. New business models that go beyond the traditional core business, such as Anything as a Service (XaaS), can be one digitally enabled evolution for a traditional business. A holistic data strategy can support the evaluation of the value of data for a business and identify new untapped business potentials.

Two – Digitizing internal processes and new tool implementation

Another quite obvious business challenge with digital transformation addresses the goal to optimize internal processes and procedures. While the development of new digital products and services is very much outwardly focused, transforming processes are about focusing on internal structures. In many organizations, this might boil down to adapting internal processes so that they can function in a newly implemented digital environment. This might mean, for example, analyzing where exchanging traditionally used tools to digital ones will work, such as human resources (HR) tools. For instance a digitized self-service portal for booking leave or assigning availability for shifts could make it much easier to track worker numbers in real-time rather than relying on old-fashioned paper-based systems.

Equally, leveraging customer data to simplify and accelerate business processes can help firms to run more efficiently. For example, Artificial Intelligence (AI) systems might be deployed in manufacturing businesses to ensure supply chains are one step ahead of the game. AI-driven sales forecasting might help with inventory and financial planning, but it could also inform buyers that they'll need to order certain components to meet future orders even before they are done deals. In short, process automation is about operating with less wastage and greater efficiency, something that affects every company's bottom line. However, not every process should and can easily be digitalized. The secret lies in identifying the right areas and tools in which digitalization provides value not only to the organization itself but also to its customers.

Digital transformation key challenges that are more hidden

There are also some less obvious challenges organizations need to face today during their digital transformation. Although many digital transformation challenges faced by organizations and their potential solutions are, in fact, relatively clear, some might not be. What are those hidden challenges, and why are they sometimes not so easy to identify within certain organizations?

Three – Developing a holistic digitization strategy and north star

Today, every digital transformation strategy needs to be based on a holistic digital approach that does not play around on the sideline. By adding a 'off-the-shelf' digital offering here or there, some organizations might feel as though they have done enough to adapt to the digital age. However, it is only by adopting a comprehensive strategy that true transformation will be achieved. Of course, any transformation, digital or not needs to fit the overall business strategy. Otherwise, business goals will not be achieved. This doesn't mean that everything other than a root-and-branch adoption of digital technologies will be enough if an organization wants to succeed. This means that its core business, as well as its organizational structures, processes, and technologies, need to be part of the transformation strategy.

Think of it like following the north star in the night sky. Although there might be a lot of change happening around it, progress in one direction is possible by sticking with the fixed point in the distance. This is why a holistic approach is often less obvious to organizations that want to change. Many will try to alter one or two things and question why a more comprehensive approach is needed at all. However, unless digital technologies are deployed throughout the organization, from the business management team to the people and organizational structure as well as the operational processes, competitors are likely to outperform further down the line. In short, for digital transformation to work, it needs to be truly transformative in every aspect.

Four – Gaining the commitment of top leaders

In fairness, digital transformation leadership challenges come in many forms. The most essential one to grasp will be gaining the commitment of business decision-makers to go about transformational change. Unless the management team is on board with a holistic approach to organizational transformation, it will be much harder to achieve the desired outcomes. In other words, the key decision-makers need to be committed to all of the initiatives that will form the digitization strategy. Even more crucial, they'll need to see it as their highest business priority.

For those driving digital transformation from below, keeping the top management on board is vital. Therefore, chief information officers will need to continue extolling the virtues of digital transformation in commercial terms. Once digital transformation begins, there should be no turning back or wavering among the top level of management. Equally, company bosses need to foster enthusiasm among their middle management teams if the project is to come to fruition in a timely manner. Business owners will need to ensure they have the buy-in of lower management levels as well as ordinary employees. Sometimes appointing champions or ambassadors of digital change can make all the difference in ensuring this sort of buy-in occurs.

Think of it like following the north star in the night sky. Although there might be a lot of change happening around it, progress in one direction is possible by sticking with the fixed point in the distance.

Five – Obtaining external capabilities by strengthening your partnerships and ecosystem

The next hidden challenge that needs to be met is how to obtain the external capabilities you'll need for your organizational transformation to succeed by leveraging your partner ecosystem. Some organizations will have some of the digital competencies they will need to transform in-house already. Others won't. Therefore, you need to understand your own core competences first and complete it with strong partnerships afterwards as even the largest organizations cannot do it alone. Regardless of the number of recruits an organization takes on board to complement its current skillset, outside partners will need to be brought in as well. This may mean a transformation in management culture too, of course, if the organization in question is not used to outsourcing some of its key processes. There are alternative strategic approaches some organizations might also like to consider. For example, companies don't always need to outsource to secure the capabilities to strengthen their ecosystem. Instead, they could look at joint ventures with partner businesses or even analyze their options with regards to mergers and acquisitions. If the skills a business needs are already abundant in a competitor, it might be worth considering to adapting it.

Six – Altering employee mindsets and ways of working

Although it is fair to say that systems, processes, and managerial buy-in are all crucial to meeting the challenges of digital transformation, there is something else businesses need to consider: people. After all, it is people who will be at the core of any successful digital transformation exercise. Unless your own staff gets on board with the concept and understands its benefits from a very early stage, it will not be the success it could be. What does this mean in practical terms, though? To begin, education is at the core of explaining why a digital transformation strategy will be better for the strength of the organization as a whole. People may feel threatened by adopting a new way of working or of increasing automation, potentially putting them out of work. However, if they are taught to realize that without a digital transformation process, the business does not have a viable future, then they'll soon come to understand why such change is needed. In other words, they need to realize that digital transformation is in their best interest and beneficial for all stakeholders.

Organizations can create better awareness about digital transformation by being open about the process. Secrecy rarely helps in meeting the challenge of persuading people about this sort of transformation. As transformation plans begin to roll out, organizations will want to alter their employee's mindsets. This won't happen unless staff members feel empowered with the digital tools they're now expected to use. In short, it means investing in high-quality employee training so staff can adapt to the new way of working. In some cases, decentralizing decision-making to a departmental level can help people to feel more in control of the change process. Agile ways of working may be introduced thanks to digital technology, but it may still take a period of adjustment to ensure full commitment. People still often want human interaction when they're at work, so it's important to give employees time to adjust their mindsets and habits. The bottom line is that employee buy-in is crucial. Therefore, without educating your people about the new technologies and processes they'll be expected to use, your transformation simply won't work.

Seven – Keeping hold of the ownership of business digitization