Revving up Automotive Manufacturers for the Circular Economy

Revving Up Automotive Manufacturers for the Circular Economy

According to the World Economic Forum (WEF), the automotive industry is “dramatically overshooting its estimated carbon and resource budgets.” Automotive manufacturing is a major contributor to a global industry that requires the extraction and processing of more than 100 billion tons of materials every single year, which causes 90% of biodiversity loss and water stress, and about 70% of the world’s carbon dioxide emissions.

Moving from a linear to a circular economy will reduce this burden on the planet’s resources, minimize waste, and give the most pioneering manufacturers a competitive advantage. The WEF predicts that circular economy will yield up to USD 4.5 trillion in economic benefits by 2030.

However, to benefit from the circular economy, automotive manufacturers need to get ahead of the curve on future regulations, sustainability goals, and customer expectations.

All signs point to a circular economy

The circular economy replaces the traditional extract-create-dispose linear economy with a regenerative model, built around recycling and re-use of natural resources. By maximizing the lifetime of finite resources, it reduces consumption and waste. This is particularly relevant for the automotive industry as it moves to replace the internal combustion engine vehicle (ICEV) with battery electric vehicle (BEV).

As the International Energy Agency (IEA) notes, BEVs require more than six times the mineral inputs of ICEVs. Considering the need to electrify the world’s existing stock of

1.3 billion ICEVs by 2050, with the total global vehicle stock projected to grow to 2.2 billion by 2050, such resource requirements are neither sustainable, nor any longer bearable.

But the imperative to move to a circular economy is not exclusively an environmental one. Global supply chain challenges have created shortages in semiconductors, leading to sales losses of more than 30% for automotive manufacturers.

Further pressure is approaching in the form of EU regulation. Brussels is set to impose minimum material recovery rates for battery raw materials such as nickel, lithium, cobalt, and copper in 2025, with increasing mandatory minimum levels taking effect in 2030 and 2035. According to the Nickle Institute, “Any company placing batteries on the EU market will have to comply with the manifold requirements in the regulation, independent of whether they operate in Europe or elsewhere in the world. All players will have to ensure that their upstream processes in mining and refining the materials, chemical processing, conversion into cells as well as assembling the batteries comply with the targets and requirements set by the legislation.”

Manufacturers should not wait to implement circularity. The circular economy offers a means of gaining a significant competitive edge in a market where nearly two thirds of customers are willing to pay more for sustainable products.

The time to kick off your journey towards circular economy is now. Buckle up. It may be a bumpy ride.

Navigating the road to circularity

By offering traceability through data transparency, digital transformation will provide the means to achieve true sustainability in automotive manufacturing. However, to achieve actual business value and leverage digital solutions in the best way, some key imperatives must be considered.

1. Creating full transparency over your vehicle’s lifecycle

Assets like the digital product passport, as introduced by the European Commission’s European Green Deal and Circular Economy Action Plan, will be essential tools for developing resource-efficient and environmentally friendly products in the future. These product passports will need to incorporate a wealth of data about how a product is built, used, and maintained, and how it may be altered throughout the different phases of a circular car’s lifecycle.

Automotive manufactures must collect data from every aspect of the value chain to create data maps and a connected digital ecosystem. This will give manufacturers and other stakeholders a fully transparent view of emissions, resource use, and sustainability.

Creating full transparency and traceability throughout the vehicle lifecycle with, for example, a digital vehicle twin will be vital in not only complying with regulations but also in reaching carbon net zero and in enabling new business models. To get there, organizations must capture digital twins for both their vehicles and the respective components and parts materials. This will help functions within an organization to extract the relevant data needed for R&D, compliance, procurement, and strategy to maximize the individual impact and make well-informed decisions.

2. Innovating new and profitable ways to recover strategic materials

The industry needs to find new ways of securing primary materials so that demand can be balanced, and materials are readily available. Shortages of semiconductors, magnesium, and wire harnesses have been exacerbated by recent challenges in the global supply chain, and they serve to highlight the difficulties that exist in guaranteeing the quality, security, and reliability of strategic materials.

The way to overcome future shortages of strategic materials is to act within an ecosystem. Partnerships with downstream players, such as dismantlers, recyclers, or shredders, can help to secure components and materials for product manufacturing by increasing the ratio of secondary materials. If automotive players work together within their ecosystem, they can create digital solutions that enable efficient dismantling and recycling processes.

Digitalization and automation have the power to transform the dismantling stage to enable product lifecycle extensions, as well as innovative strategies for remanufacturing, repurposing, or recycling. In short, these actions will help create closed loops of components and materials manageable on digital marketplaces, thus embodying the very idea of a circular economy.

3. Identifying and implementing circular business models

Companies need to evaluate both the opportunities and dangers of transforming into new business models. While circularity can help automotive players tap into new business, changing the mechanics and performance KPIs of revenue generation has its pitfalls and can often meet resistance within an organization. For that reason, automotive manufacturers must carefully design their transformation to circularity.

The design must consider the entire lifecycle of the vehicle to identify new perspectives on value which requires increased transparency. Innovating your business model requires defining future customer profiles in detail as well as respective monetization details. In a next step, businesses need to evaluate what aspects within the business ecosystem can move towards a circular business model. New revenue streams might arise through extending the vehicle lifecycle, by building networks in platform models, or from “as-a-Service” (aaS) models to increase the usage of a single product. Extended vehicle lifetimes, for example, can help drive different perspectives across an organization. Assessing the effect of circularity actions on existing business models can help identify new opportunities to create value for customers across the automotive ecosystem. Partnering with organizations that offer access to existing circular business models and aaS models can be a good starting point when it comes to analyzing which new business opportunities make sense for customers. Automotive players can then prioritize use cases and define a respective roadmap.

As an example of what’s possible, Chinese automobile manufacturer NIO has already pioneered the battery-as-a-service model through battery swapping. Under this model, customers don’t own the battery but pay for electricity and battery use either on a pay-as-you-go basis or by subscription. This means that increased battery range – by itself environmentally undesirable and more costly – is no longer an issue and opens the market for more economical and environmentally friendly BEVs.

4. Leveraging Design-for-Circularity for products

There is little doubt that a combination of future regulations and customer expectations will steer companies in the direction of secondary material quotas. This can only be achieved by reassessing existing product design and architecture.

Original Equipment Manufacturers (OEM) must analyze the impact and footprint of a vehicle along the entire product lifecycle to gauge the current circularity of their products, components, and materials. Such an analysis of product lifecycles can help manufacturers formulate a product vision, value proposition, detailed product circularity requirements and future product concepts.

By implementing a modular architecture for vehicles, manufacturers can enable efficient maintenance and dismantling processes encompassing reuse, remanufacturing, or recycling, all of which are prerequisites for a truly circular approach. The dismantling of components and the separation of materials – for example, from wire harnesses and interconnectors – will be facilitated by standardizing material compositions, which is likely to deliver higher quality secondary materials.

It is worth remembering at this stage that innovations in product design and architecture have an impact across entire organizations, so senior management must lead the process for it to be successful. This leadership includes providing close support for changes in skill sets and job descriptions. Outside of an organization, these innovations also impact the whole lifecycle and, therefore, require cross-stakeholder partnerships with all partners and suppliers within the ecosystem.

Better resilience and sustainability found with circular economy

From what we have seen, circularity has the power and potential to deliver enhanced resilience and represents the key to a sustainability success story within the automotive industry.

A circular model can provide value chain resilience and offer protection against the sort of supply chain dangers that have hit the industry so hard. Increased resilience will enable organizations to mitigate operational risk and business interruption by designing new strategies for sourcing material resources and components. Keeping recycled resources within the automotive ecosystem frees manufacturers from resource dependency and shields operations from the inevitable future scarcity of raw materials.

The circular vehicle approach can deliver competitive advantages too. First movers will take a pioneering role in automotive manufacturing and will be in a position of thought leadership when it comes to use cases and business models in the automotive ecosystem. They will be more successful in attracting and retaining forward-thinking talent, and their improved sustainability will help to attract investment. Furthermore, circularity will allow manufacturers to develop new circular business models, access new markets, and diversify customer segments.

A circular approach allows for a sustainable business set-up putting first movers ahead of the curve when it comes to future regulations around emissions and material use. Slow movers risk non-compliance and potential fines.

It can also drive concrete business target setting and performance while giving OEMs the ability to leverage long-term visions to steer and monitor the relative success of circularity models in different business functions and regions.

Closing the loop with digitalization and data

OEMs, suppliers, and ecosystem players need to make strategic choices to mitigate future obligations and disruptions. But they are well advised to take full advantage of the immediate and long-term benefits of transitioning towards a circular economy that digitalization can unlock.

The goal is to close the end-to-end loop and maximize the full business potential of reusing materials and components, and to minimize industry’s impact on the planet. But to mitigate the risk, effort, and cost involved in something that has a deep impact on every aspect of a company’s operations, OEMs can kick off their transition to circularity by focusing on specific components or materials and building upwards from there.

Right now, external momentum and stakeholder requirements are dictating the future of the automotive industry. Players still can shape their position in the race towards a sustainable future. A holistic circularity mindset is key to taking a proactive and progressive role and maximize societal and business value.

Now is certainly not the time to apply the brakes.

Free whitepaper

Identifying digital service opportunities to unlock business potential in the digital age. Download our whitepaper to learn how to develop comprehensive data strategies to identify new business opportunities and prepare your company for the digital age!

Our expert

Expert

Additive Manufacturing’s Somewhat Surprising Role in Sustainability

Additive Manufacturing’s Somewhat Surprising Role in Sustainability

Additive Manufacturing and 3D printing are key enablers for more sustainable production, supply chains and services. In fact, the global additive manufacturing market is projected to grow by almost 24 percent between 2023 and 2025, and the market for 3D printing is expected to almost triple in size between 2020 and 2026. With everything from airplane parts to hearing aids created through additive manufacturing, it is clear that this technology is special and has the potential to dramatically impact business practices and address sustainability demands.

Before looking more closely into how additive manufacturing is driving a more sustainable tomorrow, it is good to take a step back and examine current manufacturing challenges. At the core of the need for improvement is that customers want everything faster and with more flexibility in quantity, which puts a strain on traditional development, production, and distribution channels. Meanwhile, the business leaders need to balance that demand with a clear need for sustainable practices and processes. In general, taking care of resources, providing greater efficiencies throughout the entire supply chain, and developing a more circular economy are all things the manufacturing sector must pull together to achieve sustainability success.

In addition, the new CO2 certification process in Europe puts additional pressure on manufacturers and supply chains. Paying for CO2 emissions clearly changes the cost-change paradigm. Producing emissions while manufacturing as well as shipping a product around the globe will become an expensive game. Tackling this issue will require a radical rethinking of the whole value chain.

Digitalization is the game changer

To dramatically overhaul the value chain, address customer demand, and reach sustainability goals, manufacturers must undergo a digital transformation. Connecting the real and the digital world provides manufacturers with the data and insights needed to make well-informed decisions on how to optimize processes and increase efficiencies.

Digitalization offers multiple opportunities to gain a competitive advantage by improving product design, factories, supply chains, and after-sales services (spare parts) with digital twin solutions. By mimicking the product or whole supply chain in the digital world, manufacturers can simulate, test, and predict scenarios in real-time while optimizing production processes and operations. Digitalization creates the necessary transparency for better decision making through access to data. Consequently, digitalization is the foundation of many of the sustainable manufacturing processes that are already in use today – everything from low-energy robotics to modern additive manufacturing methods.

Additive manufacturing is known to be a technology which is “digital by nature,” meaning that the process itself would not work without digital technology connected to it. At the process level, 3D printing has the power to alter production, supply chain, and post-sales support practices throughout the manufacturing sector.

Three areas additive manufacturing drives sustainability

The sustainable importance of additive manufacturing is more obvious in some areas than others. Here are a few known benefits of this technology:

1. Improving Resource Efficiency During Production Processes

A key advantage of 3D printing can be experienced during production. Digital methods save natural resources through more efficient processes. The parts 3D printers produce are close to their final intended shape. Barely any material needs to be removed in contrast to grinding or milling production methods.

The accuracy of today’s digital printing methods means that products are made right the first time with little need for rejections or modifications post-production. Since there are no molds or other tools required in 3D printing (compared to on-demand technology), the requested order size is made without any overproduction, waste, or additional storage costs.

Overall, resource efficiencies are ensured thanks to a combination of simulated printing processes before production runs, optimized print pathway automation, and the potential to use digital warehousing techniques to validate which parts are – or will be – most in-demand.

2. Saving Emissions By Reducing Supply Chain Lengths

Supply chain length reduction means establishing a less costly and greener supply chain. Additive manufacturing enables the creation of parts and products closer to the end consumer and could even allow for printing in customers' homes. By decoupling manufacturers from global logistical operators, it also helps to make supply chains more resilient and less susceptible to international or weather events, as well as reducing the carbon footprint. The lower supply chain costs of additive manufacturing might even outweigh the higher costs in the location of production. Emissions associated with road haulage and international shipping will be vastly reduced. Localized 3D printing hubs will be able to bundle several production runs to make transportation to end users even more efficient and sustainable.

Another key to additive manufacturing’s sustainability capabilities is that it produces fewer parts than traditional manufacturing. The thumb rule is that if a conventionally manufactured component consists of 100 parts, the same additively manufactured component can potentially consist of only 10 parts or even less. This shortens the value chain extremely including the complete energy consumption.

Think of it this way – fewer parts and production steps require less logistical expertise to move goods around the world. Additionally, fewer machines need less space / storage, less resources, and in the end less energy.

3. Enabling Smart Repairs and Upcycling Options

The after-sales aspects of additive manufacturing should not be overlooked when considering sustainability. For one thing, additive manufacturing technologies such as cold spraying or laser melting can help to lengthen product lifecycles by reproducing worn-out parts or even worn-down sections of them. For example: With a local 3D printing service, customers can obtain the necessary part and replace it, thereby extending the product's lifespan, even improving the part’s performance, or enabling new features. Maintenance services can be strongly optimized, as parts can be produced whenever and wherever needed, making the process way more effective, saving a maximum of time.

To enable this process, manufacturers need to have the relevant files available in a digital warehouse that allows end users to select the part(s) needed and print them directly. Since customers can access the parts in real-time, there is no need for warehousing of spare parts.

Taking energy efficiency in product design to new heights

Most of us can understand how additive manufacturing drives sustainability by improving resource efficiency during production or how it can save emissions by limiting the length of the supply chain. But there is one area where additive manufacturing boosts sustainability that may not be as obvious – the product design and its performance when it comes to energy.

3D product design can improve energy efficiency of products like no other technology can, not just in production but over the course of its lifecycle. Manufacturers may be surprised how easily 3D printers produce complex structures. This not only saves material resources, but it also saves the energy used to generate the material. With additive manufacturing it is also possible to produce significantly lighter products. Less weight means lower fuel consumption and lower distribution costs.

The biggest energy savings are achieved through flow-optimized design and maximization of thermal energy absorption capability. This means that, simply by optimizing parts of the bigger product slightly through complex geometries only additive manufacturing is capable to produce, it might already improve its energy efficiency significantly.

For example, with an aerodynamic part in a turbine produced through additive manufacturing you can manufacture near-shape cooling channels right below the part surface. With the increased efficiency in cooling the turbine can run at a high temperature creating lowering energy costs over its entire lifespan. In this situation, additive manufacturing optimized not only the part but the entire product, in this case the turbine.

But additive manufacturing can even increase sustainability and energy efficiency for already sustainable technologies. Take the electric motor, for instance: by printing components more precisely, the effectiveness of the engine can grow even more – to new heights.

Think, do, act – How to make additive manufacturing work for your business

A word of caution - leaders should not apply additive technology just to say they can. The technology needs to serve the business needs, solve problems, and entail significant benefits for production processes.

Here are a few things to keep in mind for successful additive manufacturing:

It’s not all about technology. While additive manufacturing can dramatically change a manufacturing business’ level of sustainability, it is not all about technology. In fact, the confidence and support of the people in your organization can make or break your success. Leaders are encouraged to remember that there is a human component regarding changes that will be inevitable when moving from legacy production methods to more sustainable 3D printing processes. Good change management programs are essential.

Optimize and design new part(s) first…based on business purpose and then print the optimized version for actual value. There is no point in copying the initial traditionally produced part. In fact, doing so, might even be more expensive. Instead, the value of additive manufacturing lies in using the right simulation tools like digital twins and Artificial Intelligence to achieve application-optimized geometries and printing them very precisely.

Invest in the infrastructure. Manufacturing enterprises must invest in the necessary infrastructure to benefit from additive manufacturing processes and the greater sustainability they can generate. Some businesses will inevitably decide to purchase 3D printers and the associated digitalization tools that go with them. However, it is also extremely convenient for manufacturers to outsource 3D printing requirements at a lower cost due to shared resources. Sharing the resources of an expert in additive manufacturing with other organizations means even more sustainable outcomes can be achieved because fewer resources need to be retained in-house for printing products, parts, and prototypes. In some cases, depending on the individual situation (location, ecosystem, and customers), there will be no need for a factory in the first place.

Shape business strategy around sustainable goals and scale accordingly. Senior managers and executives must reassess corporate strategies if they are to find the success of additive manufacturing. Furthermore, meeting the demands of customers will require the adoption of services in a portfolio more closely aligned to 3D printed solutions. Producing 3D printed product designs is the first step, but manufacturers also need to consider material choices carefully because that will directly impact future sustainability and distribution.

Putting it all together

Additive manufacturing successes and advocates have reframed the story from “the technology reducing machines in production” to focusing on its potential to expand manufacturing opportunities. It may become a competitive advantage for some manufacturers. It may change the rulebook for production. It may be the answer for radically improving your business strategy. It could be the critical action your business needs to address the societal imperative to deliver a more sustainable future. What’s stopping you from finding out?

Free whitepaper

Have your thoughts ever circled around the question: edge or cloud – cloud or edge? Download our whitepaper and learn which factors to consider when unlocking the full potential of your IIoT journey!

Our expert

Author

How Digital Twins Deliver the Holy Grail of Connected Supply Chains

Building Resilience: How Digital Twins Deliver the Holy Grail of Connected Supply Chains

Listen to the blog here:

For CEOs of industrial manufacturing firms, one of the biggest concerns arising from the COVID-19 pandemic has been supply chain disruption. One study put the average cost to large businesses (those with revenues above USD 1bn) at around USD 184m in 2021.

Throughout 2020, the number of organizations experiencing 20 or more supply chain disruptions increased by a factor of six, according to the Business Continuity Institute’s 2021 Supply Chain Resilience report. This ranged from the Suez Canal blockage to container pileups in Shanghai and other major ports. If this wasn’t enough, ongoing climate change issues as well as geopolitical changes were the missing cherry on top. The same report found that the proportion of senior management showing a medium or high commitment to supply chain risk rose by nearly 10 percent to 82.7%. This goes to show that these global influences have the effect of transforming supply chains into revenue assurance drivers rather than cost reduction pillars.

Faced with this increasing volatility, uncertainty, complexity and ambiguity, the number one priority for sector leaders is to build resilience into the supply chain. Due to the pandemic leaders’ priorities shifting to business continuity and their realization that connectivity is the golden ticket, the challenge lies in a successful way to accomplish this.

The Holy Grail – connectivity across the supply chain

The global supply chain market is expected to experience a compound annual growth rate of 11.2% from 2020 to 2027 – a market value surge from USD 15bn to USD 37bn. With the added speed bump of supply chain disruptions, it’s time to build resilience into your supply chain, and business leaders are reaching for plentiful and readily available technological developments to do so. Currently, the IIoT-based solution showing the most potential when creating a resilient supply chain is the use of digital twins to mimic supply chains and productivity networks.

In recent years, the digital transformation of supply chains has made them increasingly dynamic and complex. Catalyzed by the pandemic and other previously mentioned supply chain hurdles, manufacturers have sought out new ways to optimize supply chains to ensure transparency. To do so, in-depth understanding and visibility of the entire end-to-end ecosystem of suppliers and customers – their needs, strengths, weaknesses and potential risk factors – is the Holy Grail.

This ideal of a fully connected ecosystem providing real-time data starts by connecting your own supply chain. Only once you have complete visibility of your own end-to-end operations, connection with the wider ecosystem can be achieved, enabling you to create a holistic overview and transparency from customer to supplier.

Based on this holistic overview, you need to decide on your own business goals and adjust your digitalization strategy accordingly. Easier said than done? Not necessarily. The important thing is not to drown in the ocean of possibilities and to keep your eye on your business goals, letting them dictate the level of detail your digital solution requires.

Digital twins – the kick starter for connected supply chains

It’s estimated that up to 93% of all IoT Platforms will contain some form of digital twin capability by 2027. So what exactly is a digital twin? And how does it tie in with a connected supply chain? To put it simply, a digital twin is a virtual representation of a physical product or process. By feeding it with data, it can be used to model the current situation in real time, test ‘what if’-scenarios for the future and, in some instances, even provide ‘best practice’ to the modelled disruption. As such, it provides predictive insights, highlights areas of weakness or potential failure and enables timely preventative action.

By incorporating the latest technical innovations (eg multi-physics simulation, AI, data analytics and machine learning), digital twins can demonstrate the impact of usage scenarios, environmental conditions and other variables to improve the resilience of a supply chain. The digital twin is therefore the ultimate goal in connecting your supply chain, yet you need to learn to walk before you can run. Start by determining the digital journey most adequate for reaching your business' set goals and drivers. Luckily, there are a few maturity levels you can reach before chasing the Holy Grail of the digital twin, and there is likely a data solution for every organization and budget.

To provide visibility and transparency on an operational level, applying a digital map or model might suffice, as it provides basic insights into your operations. However, if you want to leverage data to simulate and explore various possible scenarios and the effects of changes before implementing them in the physical supply chain, a digital shadow might be the best approach. However, only a digital twin can create enough insights to enable real-time connection and provide concrete simulations for operational, tactical as well as strategic decision making.

How to implement a digital twin fit for your goals

The key to realizing this ideal scenario is leveraging the correct data in the correct way by the correct people. However, as with any form of digitalization, there are several factors to consider when starting the journey to executing a digital twin.

Firstly, it’s crucial to always have your goals in mind: the business outcome you want to achieve should be the foundation for your decision as to which data model to use. For certain organizations, it may not be necessary to apply an end-to-end digital twin at the very beginning of your digital transformation journey. Trying to navigate through the buzzwords and promises from solution providers and staying true to your core needs is therefore an important first consideration. Applying technology just for the sake of applying technology is never the solution!

Secondly, a digital twin is only as good as the data it gets fed. Therefore, you need to gather useful data and that’s the tricky part. When creating the digital twin, connecting your internal data is advised, as this is the data that’s readily available to you. However, it’s important not to fall into the trap of data overload, which can result in too many insights slowing down and clouding the decision-making process. Once you have an internal connected supply chain in place, you can start reaching out to your ecosystem to further increase connectivity. It’s essential to take the time to understand relevant data management solutions for your business goals and ecosystem.

Everybody knows that data is the new gold in business, and companies are often reluctant to give it up lightly. This results in a potentially complex process of connecting your full ecosystem, as you need to convince all stakeholders about the joint value that can be created through sharing knowledge and creating transparency. As soon as they’re fully connected and sharing their data, you can collectively create the most detailed digital model possible, which will benefit everybody along the chain.

However, in reality it’s unlikely that every member of your ecosystem will share the data needed to simulate a complete supply chain digital twin, but that does not mean the end of the line for your digital twin journey. The good news is that there is a sophisticated workaround to help you overcome this particular roadblock: artificial intelligence (AI). Through AI, it’s possible to model the missing data and thus fill in gaps in your data lake. Furthermore, other data sources can be fed into AI to derive expected impacts to the supply chain from striking events, for example the news of a flooding in a particular region in the world can be overlaid with your supplier base and the digital twin can preempt potential impacts and solutions.

Everybody knows that data is the new gold in business, and companies are often reluctant to give it up lightly.

Making the process match the insight

Now that your data is in place and connected, the true benefit of a digital twin emerges. Real time connection and seamless data flow will enable direct transparency of your data, and customized visualization, dashboards and alerts will allow for rapid decision making. The only question is, will your decision-making processes be able to keep up with this increased speed of knowledge?

Data digitalization and process optimization need to be harmonized, as data without a process is useless, and a process without data is inefficient. Future supply chains will be a combined learning network of humans and technology, so alongside building your digital twin, it’s important to invest in the creation of a flexible workforce willing to adapt its skillset to facilitate a bionic supply chain. After all, the most powerful intelligent network is still the human mind, and it’s fundamental in deriving and acting on the benefits of a supply chain digital twin.

Enabling and benefitting from the factor of the future

When applying connected supply chains in the industrial manufacturing environment, it is important to shed light on how their connection to the green, lean, and digital factories of the future will look like. In this specific context, the successful creation of supply chain digital twins depends on the quality of data from every factory, warehouse, or nod within the supply network. This means that it is best practice to successfully develop digital twins of your factory in the first place. This will make the trick for the whole network as data could be provided seamlessly.

At the same time, it is crucial to understand that the factory of the future and its successful operations heavily depend on seamless data flows, processes, connectivity, and agility on a large scale in order to ensure individual productivity, robustness, and delivery excellence. Ever changing markets, customer requirements and supply disruption can only be managed sustainably by building agility and reactiveness into the mix. The supply chain digital twin can be the dealmaker in this context enabling the transparency needed beyond one’s own facilities. In the end, the factory of the future, being green, lean and digital in nature, is both enabler and benefactor from the creation of a supply chain digital twin. Seamlessly, connected supply chain can build the basis for factories and whole networks to decarbonize operations.

Unlocking the potential of supply chain digital twins

Increased connection and digitization open the possibility of creating supply chain digital twins, but it’s not actually the digital twin that creates the value for your business. A digital twin is simply the vehicle you need to enable a fully connected supply chain, and the strategic connection with your individual business goals is the key that makes your vehicle perform. As a result, your entire ecosystem will gain a competitive advantage.

Siemens Digital Industries Logistics (DI LOG) has already paved the way towards a comprehensive digital supply chain twin with their end-to-end resilience solution. This platform helps both Siemens and its partners to proactively manage supply chain and operations based on real time tracking and data-driven alerting functionalities for all involved parties within the network.

Free whitepaper

Based on our unique experience in digital factory environments, we identified several company as well as use case specific factors to make the groundbreaking decision between edge and cloud. Download our whitepaper and learn which factors to consider when unlocking the full potential of your IIoT journey!

Our experts

Author

An Easier Ride: Customer Expectations with Autonomous Driving

An Easier Ride? How to Meet Customer Expectations with Autonomous Driving Technology

What started as mere science fiction is now becoming a reality. Fully autonomous driving capabilities and even Robo-Taxis and Shuttles are already being introduced in some markets, complementing the more basic Advanced Driver Assistance Systems (ADAS). The future is here, now, and we can grasp it with our bare hands.

After a relatively long period of hype, the technology is now rapidly maturing and becoming increasingly prevalent. Many drivers already rely on ADAS features, such as automatic emergency braking and lane departure warning and correction systems. While this technology makes driving even more convenient for consumers, most automotive players are still uncertain about customers’ specific autonomous driving needs and concerns.

To market autonomous driving technologies effectively, automotive players need to understand a wide range of factors relating to questions such as: How are customer expectations evolving? What are the specific pain points, and how can they be effectively mitigated? How much do customers value autonomous driving features and what is their willingness to pay for different solutions? How relevant are established brands to market these solutions to customers and are there regional or other demographic differences?

To shed some light on these questions, we recently conducted the Autonomous Driving Consumer Survey 2022. We surveyed more than 2000 participants from three regions, namely the US, Europe, and China, through a representative online panel. Our findings reveal sentiments that may raise some eyebrows but will undoubtedly give valuable food for thought to all kinds of stakeholders involved in making autonomous driving a reality. This includes, for example, car manufacturers, technology companies, but also (local) authorities, and research institutions.

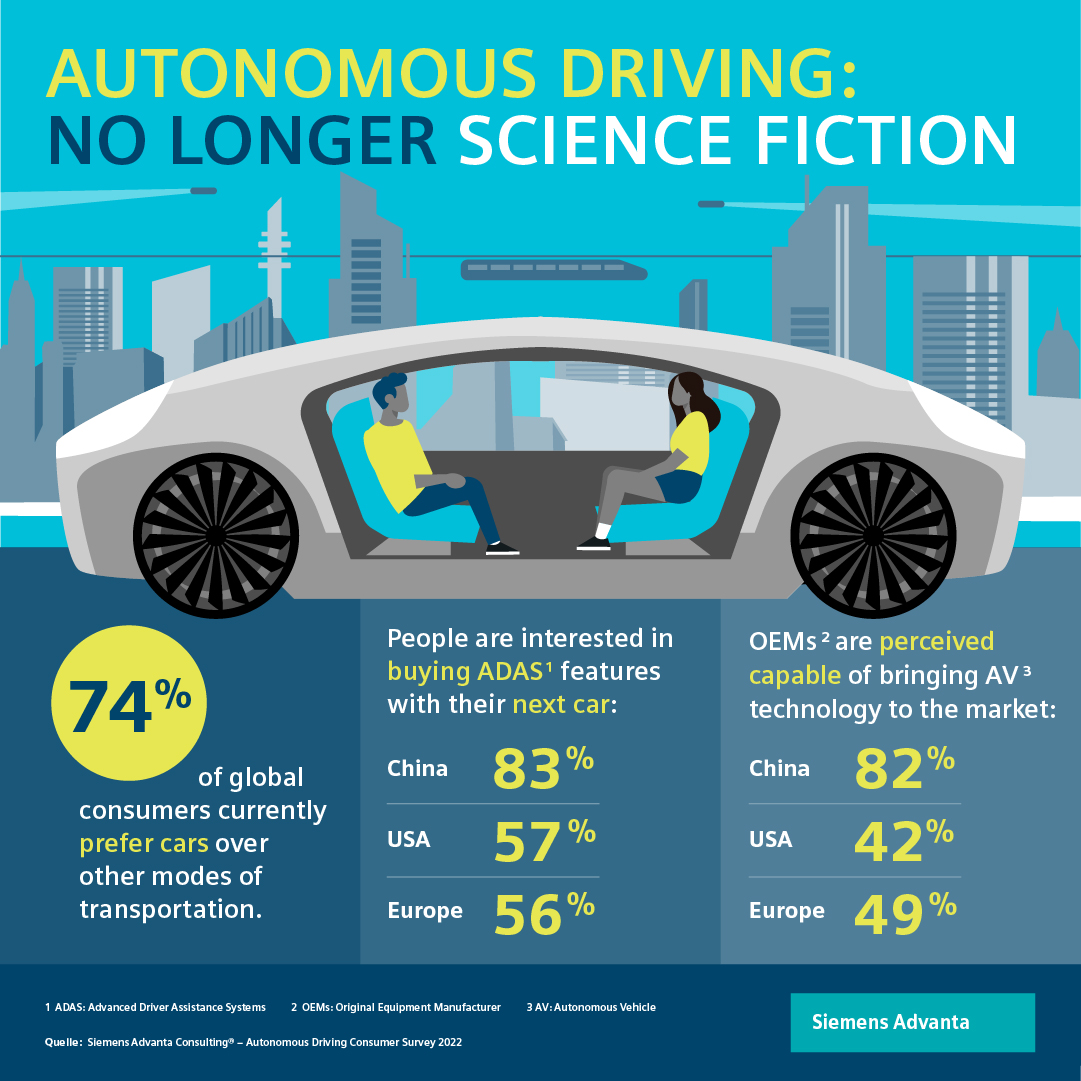

Cars and brands are still a subject of desire

Our results show that, without a doubt, people still love cars. 74% of consumers surveyed globally expressed a preference for cars over alternative modes of transport under current conditions. Even under ideal conditions (e.g., perfect availability and reliability, safety and cost, of alternative modes of transportation), the majority (59%) of respondents prefer cars. Cars will, therefore, likely stay relevant in the foreseeable future.

However, the role of currently leading car manufacturers in the future of mobility has often been questioned over recent years. Many have predicted that traditional OEMs will become increasingly irrelevant. Our results contradict this notion by showing that customers have high perceptions of traditional OEMs’ abilities to introduce AV technologies to the market. Chinese consumers are especially confident (82%), followed by Europeans (49%) and Americans (42%). Furthermore, most consumers have more confidence in traditional OEMs than in new tech companies in this regard.

On the contrary, new electric vehicle (EV) makers such as Tesla, divide regional opinions. In the US, consumers are more confident in these companies (60%) than in traditional OEMs (38%). Chinese consumers have comparatively more balanced perceptions, assigning 68% and 63%, respectively. European consumers, however, have similar faith in both new EV OEMs (52%) and traditional OEMs (52%). Contrary to common perception, these findings highlight the high relevance of both cars and traditional car manufacturers to consumers.

Driving automation needs an image boost

Chinese consumers are especially interested in ADAS, with 83% intending to purchase these features with their next car. Furthermore, 87% of them would go so far as to switch to a different car brand if that meant securing better ADAS implementation.

In Europe and the US, however, enthusiasm for ADAS is substantially lower. 56% of Europeans and 57% of Americans are interested in purchasing ADAS features, while 44% of Europeans and 49% of Americans would consider switching car brands in exchange for improved ADAS features. Still, the results highlight that ADAS features are a key differentiator for OEMs, even in these markets.

More importantly, manufacturers in Europe and the US need to establish why consumers are reticent. When asked about the reasons, the most common responses revolved around the arguments “unawareness of features” or “the system is too expensive.” These findings imply leeway for a better explanation of ADAS features and their benefits to consumers and/or finding alternative bundles or pricing models to address respective concerns.

Addressing such consumer concerns and reducing uncertainty should be a top priority for manufacturers before marketing the technology.

When asked about the reasons for their doubts, customer's most common responses revolved around the arguments “price of systems” or “unawareness of features”.

“How to pay” as a key question

There are essential factors to consider when trying to overcome obstacles for vehicle or feature purchases: pricing and payment models and differing preferences between consumer groups.

The attitudinal differences between China and the West are also evident in pricing and payment models. For connectivity services, 78% of Chinese consumers accept new payment models (e.g., pay-per-use or subscription-based), compared to just 42% of American and 34% of European consumers. However, even more striking is the difference in uncertainty in this regard, with 9% of Chinese, 29% of American, and 31% of European consumers who are not sure of whether to accept such payment models. The acceptance of new payment models for functions on demand diverges similarly (China 75%, US 36%, Europe 30%) and shows comparable rates of consumer uncertainty.

There are also important preference differences between consumer groups for other demographic variables, such as age. In the US and Europe, acceptance is lowest in the over-60s and highest in the under-30s. While this is not surprising, it’s the acceptance rates among the over-60s in China that are striking. A massive 65% of these older consumers accept new payment models, compared to only 22% of American and 15% of European over-60s. OEMs need to be aware of such demographic differences while ensuring that each payment model’s benefits are crystal clear to their consumers.

What OEMs must do to overcome these differences

What do OEMs need to take away from the messages consumers are conveying? For us, it nails down to three different imperatives.

1. Develop products that fit customers’ needs

OEMs must sharpen their focus on products that circle around customers’ needs. Developing autonomous driving features for the sole purpose of doing it won’t bring a competitive edge. Manufacturers need to realize how to make autonomous driving technologies as comfortable, easy to handle, and therefore as desirable as possible. Manufacturers should ensure their product strategies reflect consumer needs on, for example, smartphone integration and connectivity services, especially in China.

2. Develop clear pricing models that fit customers’ needs

As previously mentioned, customers’ wishes towards pricing models differ strongly, for example between regions and generations. Customer centricity and proximity are vital to addressing customer preferences and reducing uncertainty in this regard. OEMs and other automotive players should offer tailored pricing models to relevant customer sub-groups to maximize their chances of successfully positioning their solutions in the market.

3. Educate!

One of the key challenges identified in this survey is that consumers, especially in Western markets, are often somewhat reluctant to the new offerings and indifferent in their preferences. Therefore, automotive players need to advance their efforts to explain the benefits of the technology and the advantages of new payment models. This will be crucial to ensure high adoption rates and stable revenues early on. If people know “what is in it for them,” they will be more likely to press the purchase button.

Human behavior dictates highway ahead

Similar recently conducted surveys show that the ‘lack of consumer demand’ is not a barrier for autonomous driving technology adoption. Our findings support this notion. The demand is there, it just needs to be untapped. The process of getting there is simple: stay close to your customers and educate them as thoroughly as possible to tackle potential obstacles along the way.

With increased awareness, the potential to gain business value from autonomous driving is not something from a sci-fi movie anymore. It’s just around the corner.

Who knows? Maybe flying cars or time machines are next!

Download the survey

How do consumers perceive autonomous driving these days? Will the new technology influence their purchasing and mobility decisions? We recently conducted a survey asking more than 2000 participants globally this exact question. Find our key learnings here.

Our expert

Author

What OEMs Can Learn from Tesla’s Aftersales Approach

What OEMs Can Learn from Tesla’s Aftersales Approach – and What is the Company’s Achilles’ Heel

Listen to the blog here:

Tesla is a fairly new company compared to the larger and more established original equipment manufacturers (OEMs). While traditional OEMs have been around for decades, Tesla only released its first all-electric car as recently as 2008. However, to many, Tesla car technology often appeared to be one step ahead of the rest of the car manufacturing industry ever since.

Perhaps this is why we have seen Tesla stock prices soar. Investors seem to see Tesla more as a software company similar to Google or Apple rather than an automotive manufacturer and therefore value Tesla at a price-earnings ratio of 358 versus Volkswagen at 4.7 and BMW at 4.9. They tend to like forward-thinking companies with a strong vision of the future even if feasibility of that vision has yet to be demonstrated.

Tesla's success lies in the fact that it is perceived to be a leader when addressing CASE trends, namely connected, autonomous, shared and electric mobility. Its undoubted focus on data systems and the ability to leverage the full potential of digitalization is what makes the company a strong performer in today's market. Nevertheless, this focus on digital technology is just a part of the story.

Still, there have been multiple discussions in the automotive industry, as well as on Wall Street concerning the ability of Tesla to fully deliver on the promise it shows. To do so, Tesla must not only grow its fleet to maintain market share in a booming market for electric vehicles, but also further improve its profitability: Margins on new vehicle sales are often limited due to heavy price competition and the inability to reduce material cost.

Accordingly, it might be worthwhile to shift focus to aftersales as the future driver of profits. However, despite its superior position and high expectations, Tesla does not (yet) generate any profits with its aftersales business. While the 'average' OEM heavily relies on aftersales for their overall profits, Tesla still shows a deficit in their annual report.

This prompted us to take a closer look at Tesla’s approach on aftersales to better understand strengths and weaknesses.

Success factors of Tesla’s automotive aftersales process

We identified five different aspects that are essential for Tesla's aftersales setup.

Improving customer experience over the air

Leveraging the so called 'closed data loop' throughout its digital systems, Tesla is able to improve its product offering to the consumer even while it is in their possession. It can do this in almost the same way that Apple, for example, by issuing an upgrade or software update to the customer without the hardware needing to be brought into a service center. From the start, Tesla has focused on collecting data and using it for enhanced decision-making to continuously improve its products. This closed data loop has led to an irrefutable perception of sustained value and reputation among consumers. There is an associated risk with this success factor, however, which should not be overlooked: Since more data is collected and more functions can be manipulated over the air, the data security risks increase, as well. Furthermore, as vehicles sustain their perceived value for longer, future new car sales may be in danger since older but upgraded vehicles are still cutting edge.

Enabling hardware iterations

One major advantage is Tesla's ability to rapidly iterate its hardware. Being relatively close to the customer means that the firm can be very responsive when dealing with customer feedback and demands. Nonetheless, more product variance means increased cost of complexity. This could become a liability in the longer term, if it is not managed very carefully: Each introduced variant must be serviced and maintained throughout the product lifecycle. Establishing a strong Product Lifecycle Management will be essential for OEMs of the future if they want to control complexity costs while rapidly adjusting to customer desire. It can even be beneficial to design the vehicle in a way to avoid hardware changes. This can be achieved by realizing functions via software rather than hardware and by slightly “overequipping” the car. This approach would then later use the additional computation power, bandwidth or sensors / actuators to implement additional functions via the closed data loop.

Adapting to legislative constraints

Tesla chose a high-risk, high-reward strategy with respect to the various legislative and regulatory constraints it faces in different markets. This strategy allows the company to make very quick progress with nascent technologies, such as autonomous driving systems. Assessing the risks of potential legislation in areas like autonomous driving and data privacy has been cornerstone to Tesla's success so far. However, it necessarily exposes Tesla to significant liability risks. In many cases Tesla will set the standard by being the first. But what happens if legislation demands a different approach later on? As an example, Tesla currently faces minimal legislative coverage in the way it locks in customers to its systems and services. As the discussion around the “right to repair” demonstrated vividly, future legislation in markets, such as the EU, could open up competition and undermine the “closed ecosystem” strategy. If Tesla continues in this potentially risky manner but plans sufficient mitigation for future legislation, then it should be able to enjoy continued success.

Embracing a start-up mentality

Despite the rapid growth it has experienced, Tesla has successfully managed to maintain its “start-up mentality” in its governance setup. Unlike most major car makers, the company does not have a highly complicated governance operation. Indeed, Tesla is still running numerous strategic decisions through the firm's headquarters. This means the company can operate in an extremely agile way. However, with increasing sales volumes abroad and the potential for different legal restrictions, the central approach might complicate satisfying local customer demands. Also, as more and more spare parts are needed, establishing a local supply chain is becoming increasingly practical. Consequently, it might become even more attractive for Tesla to shift away from the centralized approach – while OEMs on the other side need to become more agile.

Tesla has successfully managed to maintain its “start-up mentality” in its governance setup.

Service footprint and quality as Tesla’s Achilles' heel

In our analysis it became obvious that the company's service footprint and quality is not such a clear-cut case and might even be Tesla’s Achilles’ heel. Tesla is working to establish a lean service network and can provide mobile solutions to its customers. However, success in this field is limited: still, Tesla’s aftersales support needs significant improvement. Customers, for instance, criticize having to wait very long for appointments, low availability of spare parts, difficulties to reach customer service as well as low quality of the work provided. A 2019 study of Bloomberg showed that roughly 20% of customers claimed to be dissatisfied with timelines of service and adequacy of repairs. Interestingly, between Q4 2019 and Q4 2020, Tesla grew vehicle deliveries by 60% (from 112k to 180k) while store and service locations grew by 20% only.

The underlying problem seems to be a structural one: Tesla’s fleet has been growing at a pace which the aftersales network simply couldn’t keep up with. Spare parts are scarce due to most resources being used for vehicle production. The prioritization of new vehicles sales was right to grow the fleet and capture a significant market share. Now, as the BEV market booms, Tesla must continuously increase output to at least retain their current position. At the same time, it is imperative to build a strong aftersales network and significantly improve customer experience. This requires strong investments which of course will have a corresponding impact on Tesla’s balance sheet. However, the cost of failing to invest in the aftersales network might not be financial only. It could put the firm's closed ecosystem approach at risk as they would have to rely more on third-party partners to handle service requests. Dissatisfaction could ultimately also impact new vehicle sales.

Overall, Tesla is leading the pack in four out of the five dimensions we investigated. Tesla's Achilles' heel turns out to be the service footprint and quality. OEMs seeking to optimize their aftersales setup will want to learn from Tesla's best practices while playing to the strengths and quality of their existing service networks. Development potentials lie in closing the gap between them and Tesla for software and hardware product improvements, agile mentality and fast legislative adaption. At the same time, they should leverage their advantage in the service footprint and quality to provide superior customer experience. So, what should OEMs focus on immediately?

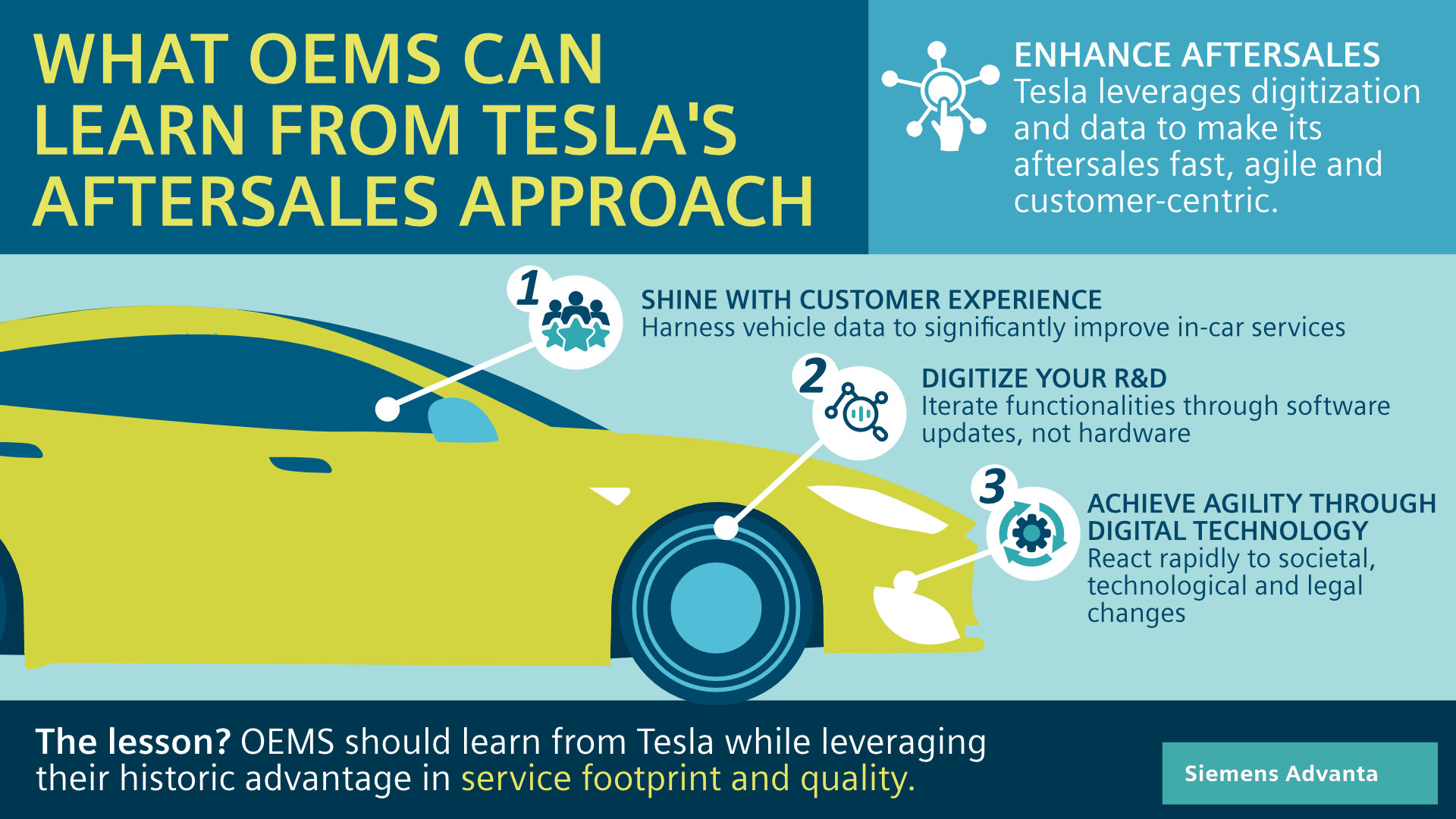

What can OEMs learn from the Tesla example?

The main thing that OEMs can take from the case of Tesla is that they ought to leverage digitalization even more than they currently do. Tesla clearly shows several best practices and market-leading processes with respect to customer-centric operations. Because of its world-class data-driven business systems, its operational model is able to provide rapidity of action in the marketplace that few others could even hope to match. This means that OEMs can learn from Tesla's best practices regarding digitalization in three distinct ways:

Shine with customer experience

It is not just in the automotive sector that customer experiences are now closely entwined with their digital experiences. However, in car manufacturing, there is a specific way that OEMs can harness data to improve their customers' experiences. This would include leveraging data drawn from vehicles in the field to continuously seek new ways to improve software and in-car services. Doing so opens the door to the creation of new or additional revenue streams. Will customers pay for software upgrades and new digital services? The likelihood is they will, especially if the customer experience is demonstrably improved by such offerings. What's more, OEMs can benefit from direct-to-customer sales with this model and not rely on dealerships or other third parties.

Digitizing research and development

Secondly, OEMs should learn that the feedback data they obtain from the fleet that is on the road is invaluable to their future R&D processes. With data flowing in almost constantly, analyzing it well will mean being able to quickly iterate product features that have the highest customer relevance or demand. OEMs must make this data easily accessible to product designers to enable well-founded decisions. Furthermore, R&D teams should shift to implementing new functionalities in software updates – rather than with hardware – to allow greater speed with the rollout of new features, such as autonomous driving systems, for example.

Utilize digital technology to revise risky behavior

Finally, OEMs should learn from Tesla's corporate governance model and set up a more agile organization, one that is more able to react rapidly to technological change. Digitalization means embracing a fast-moving world in which risk-taking behaviors can be beneficial as long as they're based on solid data. Unforeseen developments in society, technology, and legislation need a governance structure that is prepared for them, and only big data analysis can help to inform the future size and shape of any commercial operator in the automotive sector. For most OEMs that will mean to tear down the silos that have established over time. With the fundamental shift we see in automotive, fundamental innovation is required: Salespeople must work with R&D and product management to find a solution for one global problem instead of focusing on many smaller local topics.

Why automotive aftersales service remains crucial in the digital world

In summary, Tesla is a shining example of how OEMs can challenge the status quo. At the same time, the weakness in aftersales service footprint and quality as their potential Achilles heel demonstrates the value of grown structures and established networks. Although Tesla’s growth is breathtaking, there are limitations on how quickly they can build a strong aftersales presence.

The strength of traditional OEMs has been with their existing production and sales volume. This has allowed them more room for strategic action in building a sustainable and profitable aftersales network. OEMs should seek to exploit this natural advantage to convince clients with superior service as they introduce more and more BEV vehicles. At the same time, they should follow Tesla’s example and leverage their current aftersales networks to help them unlock the potentials of digital transformation and significantly improve their aftersales by digital means.

Free whitepaper

Read our whitepaper to learn how to develop comprehensive data strategies to identify new business opportunities and prepare your company for the digital age!

Our expert

Author

In Technology We Trust

In Technology we Trust: How Can your Company Ensure its Tech is Ethical?

Listen to the blog here:

As the global pace of digitalization accelerates, businesses are becoming ever more immersed in technology, regardless of sector or core activity. But the rush to establish a use case and demonstrate the Return on Investment (ROI) has tempted many to overlook the ethical implications of technology.

But what exactly is ethical tech?

The World Economic Forum defines it as technology with a clear moral dimension. It should be designed and deployed with sufficient forethought to account for and promote human and corporate values, ethics and norms with fairness and transparency at their heart.

1. What benefits can ethical tech offer transitioning organizations?

First, it’s a golden opportunity to promote and safeguard a trustworthy reputation and avoid damage. It’s clear that there is a huge and proven potential of digitalization as a force for good within both business and society. However, mistakes happen as the field of Artificial Intelligence (AI), for instance, is fairly new and undefined, and many companies and institutions are still experimenting. These mistakes attract a lot of media attention, such as Amazon’s HR program that evaluated job applicants’ resumes to the detriment of women, or Facebook’s AI robots that had to be shut down after they started speaking to each other in their own language. Consequently, such cases raise general unease over the use of AI in decision-making and are cause for concern. Nonetheless, it’s important to state that these mistakes give a boost to development. It’s up to us to learn from them fast and establish improvements to build ethical tech in business and society.

Developing and embedding an ethical technology mindset in your organization when undergoing a digital transformation is crucial, since the consequences of an ethical tech incident can be substantial. With evolving digital technologies, ethical standpoints must evolve, too. What effect does it have on your customers, partners, shareholders, and employees? In the long term, an ethical tech company can enjoy competitive advantages by the chance to earn the trust of stakeholders by promoting human values.

How can you embed ethical tech into your digital transformation from the very start?

2. Transparency with data

Conveying a clear message on how you use data, and why you use it, should be a priority for executives committed to transparent operations. With ever growing quantities of data collected and stored from an increasing number of devices and sensors, an organization’s capacity to interrogate and analyze that data to gain valuable business insights becomes more enhanced by the day.

For instance, consumers’ personal details are now routinely collected and combined with an array of information harvested from their digital footprint. This might include social media posts, the route driven to the office, the buying history, internet search histories, and so on. The importance of data should not be underestimated; with society claiming the right to shine a light inside business practices to confirm whether corporate values align with their own, proactively ensuring transparency in how data is used becomes a business priority. This is also true for companies operating in the B2B sector since stakeholders are increasingly interested in ethical tech in the entire supply chain.

How can you establish data transparency?

An organization’s approach must be guided by a moral and human compass. To become an ethical tech company, leaders first need to establish and publicize company values. These should be based on customers’ expectations of openness and consent; The guiding principles of the General Data Protection Regulation (GDPR) illustrate that for the European Union: lawfulness, fairness, transparency, integrity, and confidentiality. That gives some guidance for the use of new technologies involving data and AI to strengthen our democracies, give people a voice and make meaning out of data to create a better future. Second, it should be ensured that the way data is used aligns with the organization’s values.

The overarching imperative for digital organizations should be to work on building trust in the security of that data and promote transparency around its usage. And that starts with policy and procedure. That’s why it’s important to build a robust data usage. This involves categorizing data methodically and keeping close tabs on all employees who have access to it. Everybody can then be aligned around your company’s approach to accountability for data, how that data is used and how it’s protected.

As a crucial part of ethical tech, cybersecurity should be baked into your plans from the beginning, with digital transformation risk assessment undertaken as your project is being developed. It should feature at every stage and needs to be preventative, detective and defensive. This reflects the reality that security is a multi-faceted and on-going challenge, and one that responsible and ethical tech companies rely on to build trust in their use of data.

By gaining user trust, companies will be able to gather more and more data to enhance their specific offerings. Many argue that the real value for users and customers will be lifted when companies start collaborating more in ecosystems, rather than trying to reap small gains through acquiring more data than their competitors. However, moving from ego system to ecosystem doesn’t mean that you share your data indiscriminately with everyone. Ecosystem means that you share information only with trusted partners who have a common and aligned approach to collaboration, where it is clearly defined who contributes what to achieve a common goal – for the good of companies and its clients.

With society claiming the right to shine a light inside business practices to confirm whether corporate values align with their own, proactively ensuring transparency in how data is used becomes a business priority.

3. Respect stakeholder privacy

A commitment to an unambiguous approach to privacy will help to build stakeholder trust in the protection of data. Historically, big data has been characterized by a ‘catch-all’ approach to maximize data collection, allowing organizations to quantify an individual’s everyday life to the benefit of the company collecting the data. Because organizations have been keen to exhaust all its inherent value, it’s not been uncommon to sell on or share customer data in a secondary market.

But most customers don’t fully understand the specific purposes behind collecting and sharing personal data. A fear that many users have is that their information is accessed by unknown parties and that their everyday choices are being tracked, ultimately undermining their trust in the privacy of their data. Though being mostly illegal but hard to trace, algorithms designed to influence political opinion, or to promote “fake news”, are presenting us with ever more dangerous applications that have the potential to erode privacy.

How can you establish stakeholder privacy?

Go out of your way to demonstrate good behavior and compliance, and actively seek to banish opaque policies that technically tell the truth, but don’t quite tell the whole story. Carte-blanche to use data as you like is no longer acceptable, and if your organization has plans to sell personal data onto third parties, your customers need to understand that in full, actively give their permission, and be prompted to grant that permission at regular intervals.

Giving stakeholders control over their data builds transparency and aligns your organization’s everyday activities with the values it outwardly promotes. This is already a legal requirement in some jurisdictions; in the EU, for example, the GDPR outlaws any processing or use of data that an individual has not given consent for. In fact, it explicitly states that “data subjects” can withdraw consent whenever they want, and those who hold the data are obliged to comply.

4. Build trust in technology

A variety of more sophisticated technologies, including AI and machine learning (ML), continue to move into everyday life. According to The Harvard Gazette, global corporate spending on AI software and platforms is expected to top USD 100bn by 2024.

In addition to some of its most visible and benign uses in buying recommendations on websites or in translation tools, AI is also already used in a wide array of more critical scenarios, from helping medical diagnoses and assessing mortgage applications to keeping driverless cars safe. As a result, human oversight is instrumental, not just to ensure that disaster can be avoided in the event of technology breakdown, but to act as ultimate arbiter of a technology that is still likely to produce further ethical dilemmas. In short, ethical tech requires humans to be responsible and accountable for the final decision, not AI. Complex decisions should be more transparent, with the roles of AI and human intervention clearly visible in the process.

How can you establish technology trust?

Organizations must establish processes to ensure that they and their stakeholders know exactly what technology is being used, where it’s being used and how. Creating trust among clients, partners and employees is dependent on ensuring methodical and consistent human oversight of critical systems.

That’s why you should encode your organization’s values. Digital technology can be developed to take account of biased training data which results in algorithms and AI decisions so that the technology operates within the bounds of your company’s values. With so much riding on client and customer trust in the fairness and ethics of modern digital systems, encoding ethical values so that they can be assessed and measured against technological business operations will help bridge the potential trust gap.

One way around developed biases is to explain how AI decisions are made. For example, with medical diagnoses that rely on AI, healthcare companies have examined ways to give each diagnosis a confidence score based on a variety of contributory medical and lifestyle factors, allowing clinical staff to follow the workings of algorithms and introduce the benefit of their medical training and experience into that diagnosis if needed. AI is not replacing human beings, it’s enhancing them. But human beings are still in charge.

Taking it a step further, Explainable AI (XAI) is bringing further transparency to decision-making. Defined as a system that can explain its decisions, as well as the rationale for those decisions and some notion of how it might behave in the future, the self-learning AI platforms that power driver-less cars, for example, now have the ability to “explain” their choices. In this case, choices such as changing lane or accelerating or braking for no apparent purpose – and how factors influencing those decisions – are weighted. Yet, research on XAI is still fairly young and many questions remain unanswered, leaving applicants of AI with the sometimes tricky trade-off between the performance benefits of an unexplainable state-of-the-art model and an explainable, but lower performing, commodity model.

Ultimately, leaders must decide how to put their company values into practice to guarantee stakeholder welfare through ethical tech. The global tech industry can only build trust by using technology in a responsible way that promotes transparency and a purpose to that technology that focuses on the good it can bring about for all of society.

5. Guide ethical tech from the top and from the bottom up

There is an opportunity for leaders to gain a significant competitive advantage by making trust a business-critical issue.

How can you establish this?

It’s equally important to drive ethical tech both from the top of your organization, and from the bottom up, too. Leaders need to communicate their company’s values and ethics, formalize them in policies and make sure technology use is aligned with those values. That process can be set in motion by making sure employees understand the commitment and dedication to ethical technology. When leaders communicate that clearly, it helps others throughout the company to buy into that sense of responsibility, and will inform ethical decisions aligned with company values.

Digital technology use cases that are specific to your company can help employees test your decision-making framework against real-life scenarios, and that framework can be used to question and adapt the way individual employees make responsible decisions. In turn, employees are then more disposed to develop a natural ethical mindset of their own, one that is more likely to manifest itself in all facets of their roles.

And that’s where the bottom-up approach comes in; by taking your cue from the Tech for Life movement – which establishes a “code of honor” for the tech community regardless of a person’s status within a corporation – you can help foster this bottom-up movement in the direction of socially responsible tech based on a human moral compass. After all, although it needs to be guided from the top in the design stage, ethical tech is a responsibility shared between each and every one of your employees across all functions.

Remember, data regulations exist to enforce broad minimum standards of protection; for example, the EU’s GDPR can penalize data misuse and breaches with fines of between 2% and 4% of worldwide annual revenue, or flat fines of EUR 10m to EUR 20m respectively, whichever is higher. Similarly, for the use of AI, the EU is acting as a driving force to establish legislation and we can expect laws and regulations to come soon. But if ethical tech comes from the bottom up and from the top with conviction, those values and ethics will infuse every decision with responsible ethical corporate values, policies and procedures that guarantee even higher standards around data use.

From the bottom, from the start & from the top

Ethical safeguards, policies and procedures can only go so far. To truly master the art of building trust in a burgeoning tech landscape, you need to devise ways to equip employees with a mindset sensitive towards ethical standards. The role of leaders today is to embed those values into the culture of their organization, from the bottom, up and from the top, down. That way, you’ll gain trust in how you use and collect data, in how your technology is deployed to make decisions, and in the privacy of all stakeholders; top-down and bottom-up leadership will ultimately help weave an ethical technology mindset through the fabric of your digital transformation to prioritize the relationship between technology and human values. Everyone involved in tech should apply human principles guided by an ethical compass to ensure that tech is used in a responsible way.

So, set out today to make sure your organization is becoming an ethical tech company in parallel to embarking on your digital transformation; start at the planning stage, apply ethical tech standards iteratively depending on your industry and business, and your efforts can offer a competitive advantage in the form of the trust of stakeholders, clients, and investors alike.

Free whitepaper

Download our whitepaper and learn how to develop comprehensive data strategies to identify new business opportunities and prepare your company for the digital age!

Our expert

The Route to Connected Vehicles of the Future

The Route to Connected Vehicles of the Future: How Edge & Cloud Ecosystems are Paving the Way

Listen to the blog here:

The number of connected vehicles around the world is growing rapidly. It's estimated that by 2025, when 100% of all new vehicles to market will be connected, there will be more than 400 million connected passenger vehicles alone. More connected cars require connected vehicle ecosystems in smart cities to function efficiently. The market is expected to see a compound annual growth rate (CAGR) of 17% between 2019 and 2027, amid increasing population density in urban areas. According to the UN, nearly 70% of the world’s population will live in cities by 2050. So, the performance of modern networks to support connectivity is becoming even more critical.

Whether automotive industry players will be successful or not depends on how they leverage ecosystems and combine technologies like edge and cloud computing. In tandem, they can deliver a wealth of benefits, including safe and reliable autonomous driving, energy optimization and real-time navigation, as well as new data and subscription services.

To pave the way for connected vehicle ecosystems, read on!

1. Why connected vehicles and their ecosystems will fuel the future

So what, exactly, is a connected vehicle? It’s one that can be linked to different services and devices via wireless networks. This includes other connected car technology such as software, entertainment and communications, or parts of infrastructure such as traffic signals, emergency centers and navigation aids, as well as other vehicles, and even bicycles, cyclists and pedestrians.

A connected vehicle ecosystem refers to everything that will connect to the car via smart-city platforms. It’s the sum of every fixed or mobile device or sensor that can connect to tomorrow’s cars. It will be able to collect and process information on everything from location, weather and driving conditions, to parking availability, congestion or hazards ahead.

In short, both will become part of tomorrow’s inner-city networking with a seamless and continuous exchange of information and data via fixed devices, sensors, and via the edge and automotive cloud services.

As 5G grows, and eventually gives way to 6G a decade or so later, those connected vehicle ecosystems will be key to providing state-of-the-art vehicles with the ability to become sentient machines. They will rely on the transfer of data through wireless communications for everything from situational awareness to predictive maintenance.

How will this benefit users?

Broadly speaking, the term “users” will include not just passengers: fleet owners, smart cities, original equipment manufacturers (OEMs) and original equipment suppliers (OESs) will all stand to gain, too.

Connected vehicle technology will offer services including driver assistance, safety features, entertainment, well-being, as well as vehicle and mobility management. Vehicles could receive rapid product iterations over-the-air to further improve software functions. Users will be automatically connected to ecosystems to enable easier road charging and reactive traffic monitoring and management – improving the driving experience significantly.